In an era where environmental consciousness is becoming increasingly crucial, businesses across various industries are seeking innovative ways to reduce their carbon footprint and embrace sustainable practices. One such innovation that holds immense promise is 3D printing, also known as additive manufacturing. Whether you’re in manufacturing, industrial design, aerospace, healthcare, or beyond, integrating 3D printing into your operations can propel your journey toward environmental sensitivity and sustainable development.

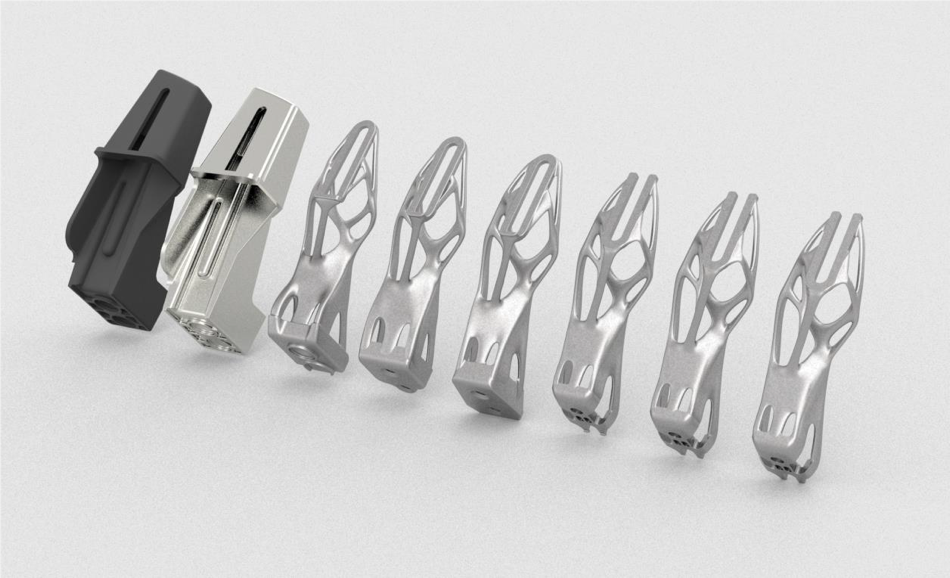

Traditional manufacturing methods often entail substantial resource consumption, generate significant waste, and contribute to environmental degradation. In contrast, 3D printing presents a paradigm shift by enabling the creation of parts, models, prototypes, tools, and final products through additive processes. Instead of subtracting material from a solid block, 3D printing builds objects layer by layer, using only the necessary material. This approach significantly reduces raw material consumption and minimizes waste production, marking a significant step towards sustainability.

The sustainability advantages of 3D printing extend beyond material efficiency. According to the U.S. Department of Energy, additive manufacturing has the potential to slash waste and material costs by nearly 90% while halving manufacturing energy consumption compared to traditional methods. These statistics underscore the compelling economic and environmental benefits that 3D printing offers to businesses worldwide.

*source : https://all3dp.com/4/7-ways-3d-printing-helps-you-become-eco-friendly/

Let’s delve into the environmental benefits and considerations of incorporating 3D printing into your business:

- Reducing Carbon Footprint

The transition to 3D printing can substantially decrease carbon emissions, with estimates suggesting a potential reduction of up to 5% by 2025. By optimizing energy consumption and minimizing waste, businesses can significantly mitigate their environmental impact. - Biodegradable and Renewable Materials

The materials commonly used in 3D printing, such as PLA and ABS, offer environmental advantages. PLA, derived from renewable sources like tapioca and corn, is biodegradable, while ABS, though derived from petro-plastic, is recyclable. This shift towards sustainable materials aligns with the growing demand for eco-friendly practices. - Extending Equipment Lifespan

One of the remarkable aspects of 3D printing is its ability to create spare parts for various equipment, thereby extending their lifespan. By facilitating repairs and replacements, businesses can reduce the premature disposal of machinery, contributing to resource conservation. - Addressing Supply Chain Challenges

The decentralized nature of 3D printing enables localized production, mitigating supply chain challenges associated with transportation and distribution. Companies can produce goods closer to their markets, enhancing efficiency and reducing reliance on long-distance shipping. - Minimizing Shipping Needs

As 3D printing services become more accessible locally, the necessity for extensive shipping diminishes. This shift towards on-demand production near the point of consumption not only reduces transportation-related emissions but also enhances logistical efficiency and cost-effectiveness.

- Reducing Carbon Footprint

Summary

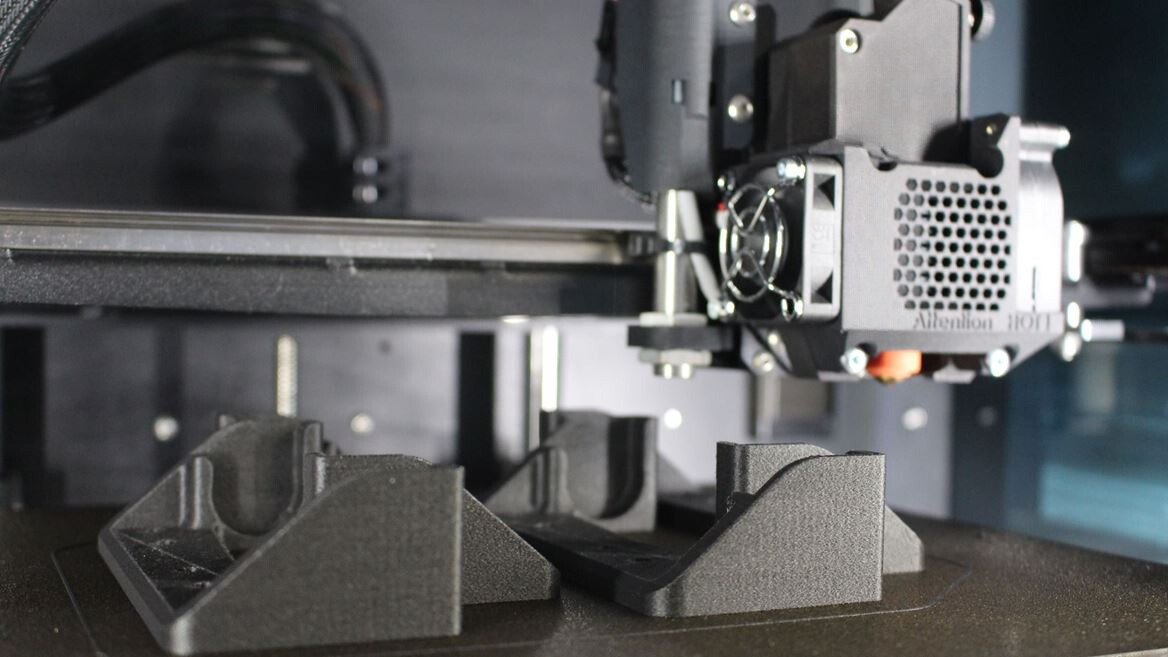

Projet firmly believes that 3D printing holds immense promise as a sustainable manufacturing solution. As industries continue to evolve, the integration of 3D printing into sustainable practices represents a crucial step towards building a greener and more resilient future. At Projet, we are committed to supporting this journey by offering a diverse range of capabilities, including cutting-edge 3D printing technologies such as FDM, SLA, and SLS.

Additionally, our solutions encompass rapid prototyping, mechanical design, and reverse engineering, providing comprehensive support to businesses seeking to incorporate sustainable manufacturing practices.

We are eager to collaborate with your company and provide tailored solutions to meet your specific needs and objectives. Together, we can embark on a path towards sustainable growth and make a meaningful contribution to a more environmentally conscious world. Contact us today to explore how we can assist you in integrating 3D printing into your sustainable initiatives and drive positive change for the future.

Connect with Projet:

If you’ve had a positive experience with Projet that you’d like to share, we’d love to hear from you! Reach out to us at [email protected]. Your feedback is incredibly valuable to us and plays a vital role in our ongoing efforts to enhance our services.

For further details, explore our other webpages for comprehensive information about our services and how to contact us. Our team of friendly professionals is standing by, eager to assist you. We can’t wait to connect with you soon!