1-Stop 3D Printing Service Provider Malaysia & Singapore

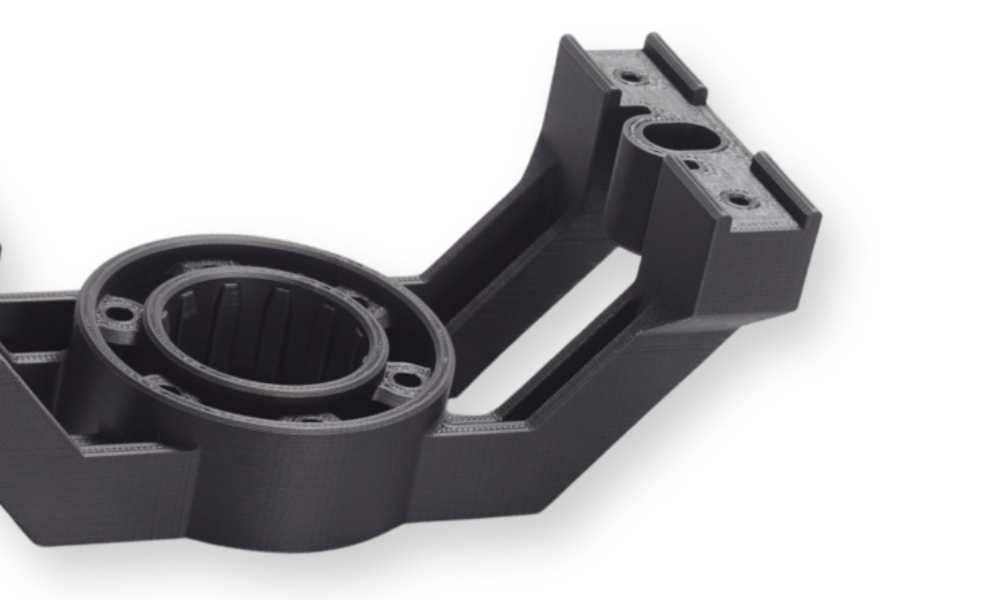

We offer one of the fastest and most comprehensive manufacturing solutions, including 3D printing services across Malaysia, covering Penang, Kuala Lumpur (KL), Selangor, and Johor, as well as in Singapore and other international regions. Our services is ideal for rapid prototypes and intricate functional parts for larger-scale production without MOQ. Projet’s facility is equipped with experience industrial design engineers and advanced additive manufacturing technologies, covering Fused Deposition Modelling (FDM), Selective Laser Sintering (SLS), Selective Laser Melting(SLM), Multi Jet Fusion (MJF), Projection Micro Stereolithography (PµSL), and Stereolithography (SLA). You can expect rapid delivery of finely-produced, precise and quality assured parts, your project is in capable hands.

Urgency Resolution Is Our Business

Whether quick prototypes or large-scale production parts, choose Projet’s 3D printing services with lead time from 1 day. We are your reliable one-stop centre for custom fabrication, offering a comprehensive selection of over 20 materials including thermoplastics and thermosets, plus over 5 post-processing techniques. Get your next project started with Projet by reaching out to our human touch customer service personnel for enquiry or try our online instant quote for immediate pricing feedback.

ISO 9000 Certified 3D Printing Service

Bring your ideas to life with fast, precise, and affordable 3D printing solutions with no minimum order.

We offer a wide range of additive manufacturing services – from FDM & SLA polymer parts to SLM metal parts, and high performance MJF & SLS printing.

Our precision applications are perfect for aerospace, automotive, medical, robotics, industrial, consumer electronics industries, and many more. We offer CoCs, material certifications, finishing certifications, inspection reports, and hardware certifications.

With more than 30 3D printers, we have unmatched capacity that reliably delivers parts within days. In addition to a broad material selection, we offer several post-processing options to improve cosmetics or enhance mechanical properties.

3D Printing Service Online for Custom Parts

On-demand 3D printing for rapid prototyping and production in as fast as 1 day. Just upload a 3D CAD file to get an instant quote on your 3D printing design. In our quoting platform, you can see real-time cost implications based on your choice of 3D printing material and resolution level.

Click here > https://projet.my/instant-3d-printing-online/

Frequently Asked Questions:

Get an online instant quote through our online system or receive a personalized response from our customer service team within 24 hours. Our team is available from Monday to Saturday, 8:30 AM to 8:00 PM, ensuring prompt and efficient service.

The recommended file formats are STEP (.stp/.step) and STL (.stl). Therefore, if your file is in a different format, you are encourage to convert it to either STEP or STL for faster processing time.

Several factors need to be taken into consideration, such as your part size, height, complexity, and the printing technology used, as they will affect the printing time. At Projet, we take pride in our efficiency that can complete in 1 working day.

We accept payment via bank transfer or on line payment through STRIPE payment platform

For corporate orders, please contact directly to our sales team via e-mail at [email protected]. We are more than happy to be your long term contract service bureau.

We ship your 3D-printed parts worldwide directly from our facility Malaysia, using FedEx or DHL for fast and reliable delivery.

We uphold the highest standards of confidentiality and data protection. Your personal or company information and intellectual property are strictly safeguarded. Your trust is our priority, and we are committed to ensuring the utmost privacy and security.

We offer comprehensive design services. Share your ideas, concepts, and specifications with us, and together, we’ll bring them to reality.

Our competencies

We are a highly dependable mechanical powerhouse with an extensive array of additive & subtractive manufacturing capabilities. Catering from one-off prototyping to low-volume production, we offer solutions that span from basic to industrial, including cosmetic finishing manufacturing.

FDM

- Broad material selections

- Aesthetics finishing

- Size up to 500mm³

SLA / DLP / PµSL

- Industrial-like material

- Detailed finishing

- Large size

SLS

- End-use product

- Engineering material

- Good performance & reliability

Surface finishing

- Surface roughness

- Painting

- Vaccum metalization