Metal 3D printing is a good option for a variety of applications, including prototyping, manufacturing, and creating custom parts. It can be the most affordable way to make parts for low to medium volume production.

3D printing has revolutionized manufacturing by offering a faster, more flexible alternative to traditional fabrication methods. This innovative process enables manufacturers to transform designs into complex metal parts quickly, easily, and at a significantly lower cost. With its efficiency and cost-effectiveness, 3D printing continues to reshape how products are designed and produced.

What is SLM?

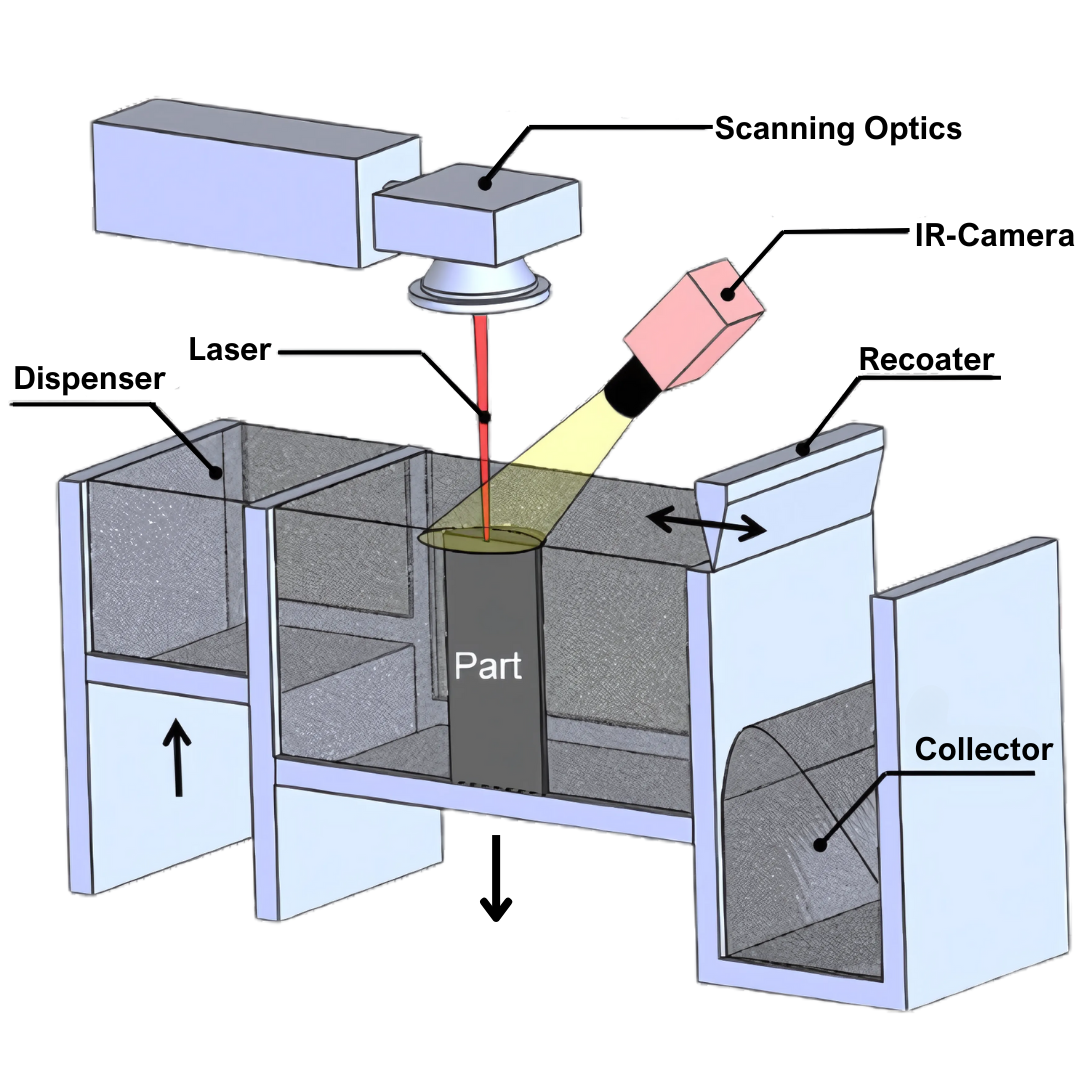

Selective Laser Melting (SLM) is a widely used 3D printing technique that belongs to the laser powder bed fusion family. In this method, a powerful laser melts metal powder, layer by layer, to build a 3D object.

The process is guided by a 3D CAD model, which directs the laser to fuse each layer of metal powder into a solid, uniform shape. This additive manufacturing technology is known for its precision, making it ideal for producing complex, high-strength metal parts with exceptional durability.

SLM machines rely on high-powered lasers to fuse the metal layers and create these detailed parts. After printing, an operator removes the completed part (or parts) from the powder bed, detaches it from the build plate, and then performs additional post-processing steps for a final finish.

3D Printing FDM , 3D Printing service Singapore , 3D Printing service KL, 3D Printing SLA, 3D Scanning Malaysia

How does selective laser melting work?

To print a 3D metal part, the process starts by preparing a digital 3D model and converting it into an STL file, which is then sent to the 3D printer. Inside the build chamber, metal powder is added and often pre-heated. A thin layer of powder is spread across a build plate using a specialized roller. A laser beam then selectively melts the powder to form the first layer of the part. After each layer, the build platform lowers slightly, and a fresh layer of powder is spread and melted, fusing with the previous layer. This layering process repeats until the final part is fully built.

Once completed, the part cools inside the build chamber, after which it is removed and separated from the build surface. Support structures are then removed, leaving the part ready for use. However, a post-processing step is typically needed to smooth the surface, as the initial finish may be somewhat rough.

SLM 3D Printing Materials

Aluminum alloys

Known for for their favorable properties, such as lightweight, high strength, and corrosion resistance. These characteristics make them highly sought after for a range of industrial applications.

- AlSi10Mg: A widely used SLM alloy, valued for its excellent weldability, high strength, and thermal performance.

- AlSi12: Known for its lightweight and higher ductility, ideal for creating complex geometries.

- A356: Offers strong mechanical properties and exceptional castability, commonly used in automotive applications.

- A357: Similar to A356 but provides enhanced strength and corrosion resistance, perfect for aerospace components.

- A6061: Features magnesium and silicon as key elements, ensuring moderate strength and superior corrosion resistance

Stainless Steel

Stainless steels are a group of iron-based alloys known for their corrosion resistance and are widely used in SLM 3D printing. They offer a combination of mechanical properties that make them suitable for a variety of applications.

Titanium Alloy

Titanium alloys are highly valued for their exceptional strength, low density, and high corrosion resistance. These properties make them ideal for demanding engineering applications. They find applications in aerospace, medical implants, and other industries requiring lightweight yet strong parts.

Tool Steels

Titanium alloys are highly valued for their exceptional strength, low density, and high corrosion resistance. These properties make them ideal for demanding engineering applications. They find applications in aerospace, medical implants, and other industries requiring lightweight yet strong parts.

3D Printing service malaysia , 3D Printing service KL, 3D Scanning Malaysia

What are the advantages of selective laser melting?

Complex Geometries:

SLM enables the creation of highly intricate shapes that are hard or impossible to achieve with traditional methods, enhancing performance in applications requiring lightweight, complex structures.

Design Freedom:

SLM bypasses traditional constraints, such as molds or dies, empowering designers to create optimized, innovative parts tailored to their functions.

Material Versatility:

SLM supports diverse metals and alloys, allowing engineers to choose materials based on specific mechanical, thermal, or chemical properties.

Lower Tooling Costs:

Without the need for molds or dies, SLM significantly reduces upfront tooling expenses, providing cost-efficient production.

Metal 3D Printing Applications

- Manufacturing Tools: Durable dies, punches, and cutting tools designed for high wear resistance.

- Molding: Injection molds and die-casting tools built to endure thermal cycling and corrosive materials.

- Automotive: Precision tools for stamping and forming metal parts in vehicle production.

- Aerospace: High-strength tools and components like brackets and engine parts, meeting rigorous industry standards.

- Medical Devices: Biocompatibility and easy sterilization for surgical tools and implants.

- Consumer Goods: Ideal for products like kitchen appliances and jewelry, offering durability and a sleek appearance.

- Tooling: Essential for molds and dies requiring a hard surface to extend their lifespan.

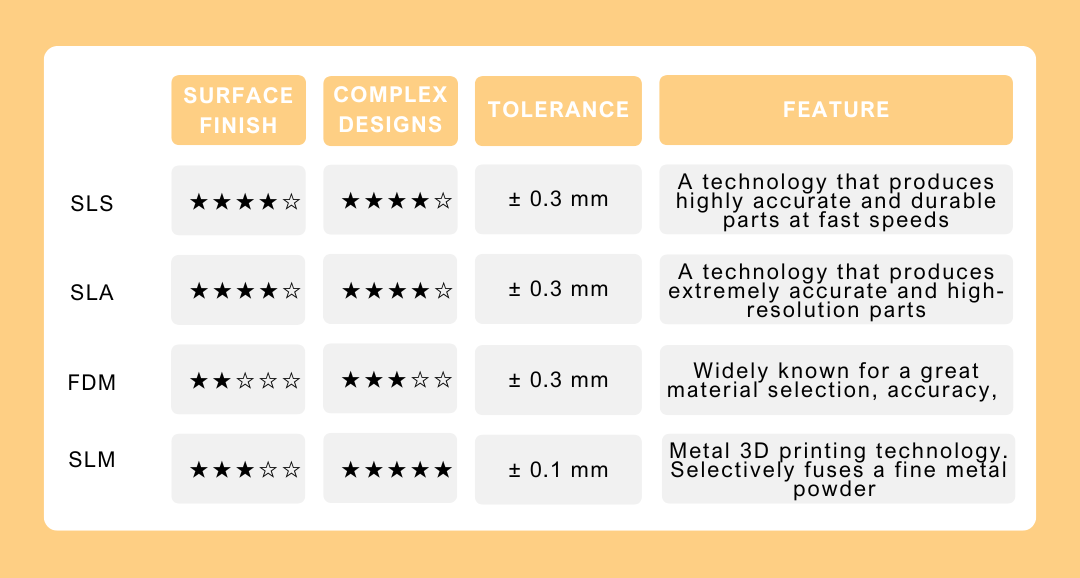

SLM vs. Competing Technologies

Most businesses that have invested in 3D printing use more than one type of 3D technology. Each has its own advantages and disadvantages, and the most complete workflow is typically one that can treat each technology as a tool to be used in different situations.

Collaborate with 3D printing bureau to choose the best material and optimize build orientation for your project’s needs. Explore our 3D Printing Materials Guide to learn about various plastic and metal materials across technologies.

Discover more about additive manufacturing at projet.my. For assistance, reach out to our applications engineer at enquiry@projettech.com or +604-2858 335.