What’s Vacuum Casting?

Vacuum casting, also known as urethane casting or polyurethane casting, is a popular manufacturing technique used to create high-quality prototypes and small production runs. Similar to injection molding, this method involves casting urethane resin into a cavity formed between two silicone mold halves.

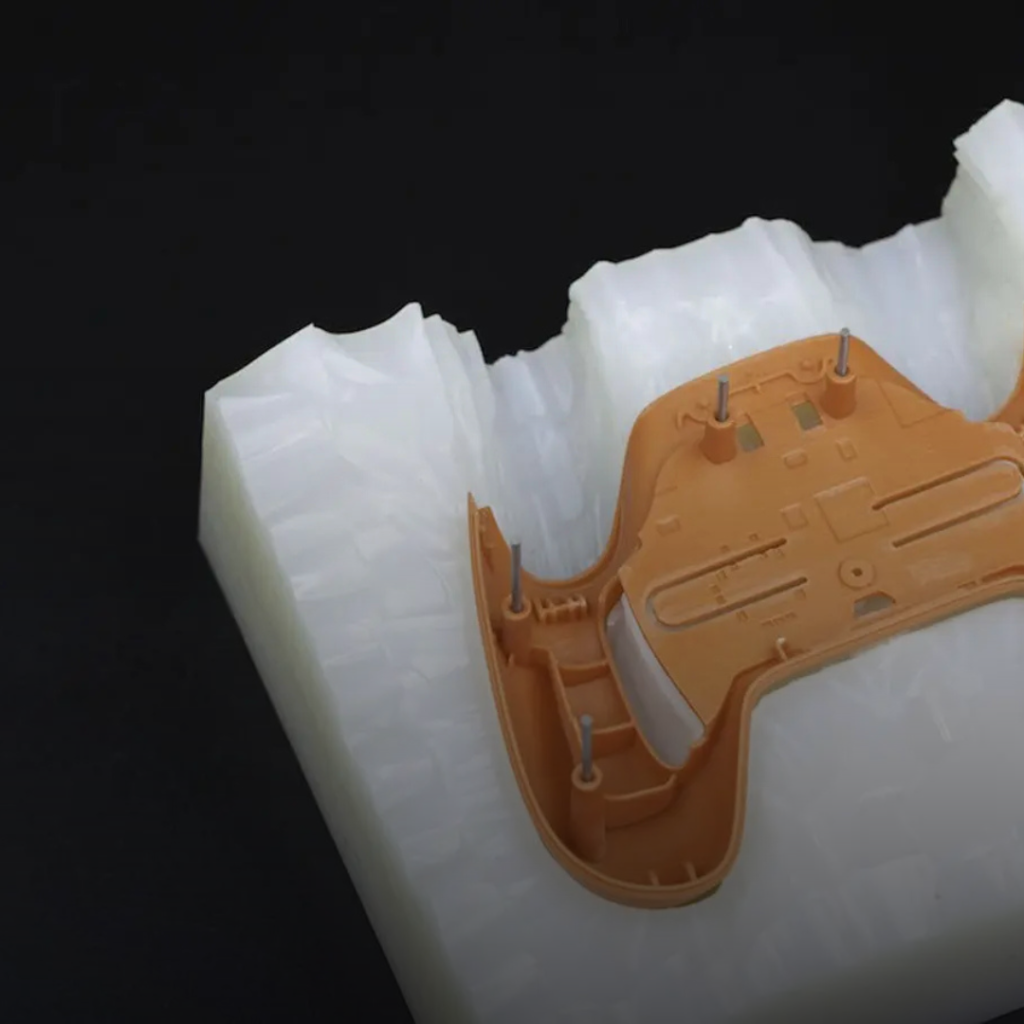

The process begins by creating a silicone mold around a master model. The mold is then carefully sliced into two parts, allowing the master model to be removed. A gating and ventilation system is added to ensure proper resin flow.

Afterward, a urethane-based resin is poured into the mold cavity and cured under a vacuum, preventing air bubbles from forming and ensuring a flawless final product.

Vacuum casting is especially useful for industries like automotive, aerospace, and electronics, where precision and quality are crucial.

Note: Vacuum casting is better known as urethane casting or polyurethane casting in the US.

Why Choose Vacuum Casting for Medical Device Manufacturing

Material Versatility

Medical devices usually use different types of plastics, each with certain characteristics. The silicone molding technique supports most of the commercially available plastics and resins. This includes ABS like, TPU like, PP like, POM like, PC, PA like, and PMMA (Acrylic). That’s why it has a range of applications just in the medical industry.

Cost-Effectiveness for Small Batches

In medical device manufacturing, especially when you’re in the development phases, cost is crucial. You don’t want to spend a lot on prototypes and tests. Here, vacuum casting is better than other rapid manufacturing techniques.

It has a low setup cost; you only need a master mold and resin materials. The silicon itself is cheaper. Moreover, one mold is enough to make up to 25 copies. And unlike other machines, you don’t have high-powered machines that consume significant electricity. So, overall, a low-operational cost.

Speed of Production

Speed of production is also vital in the medical field. Researchers require a process with a faster turnaround for testing hypotheses in the shortest time possible. Compared to techniques like injection molding with 2 to 3 weeks lead time, vacuum casting reduces this to 10 to 15 days.

Flexibility in Design Changes

In die casting, permanent metal molds make design changes difficult and expensive. However, silicon molds are cheaper and easier to prepare. After making a certain batch, you can recreate or make amends in the mold design with a little cost.

Industrial Applications of Flame Retardant Materials

Automotive Industry

Flame-retardant materials play a crucial role in the automotive industry by ensuring compliance with fire safety regulations. These materials, such as flame-retardant ABS plastics, are commonly used in interior components like dashboards, upholstery, and wiring harnesses. By reducing the risk of fire during collisions or electrical malfunctions, they enhance vehicle safety and durability.

Electronics Industry

Flame-retardant materials are critical in electronics to protect sensitive components and ensure products comply with fire safety standards. These materials are widely used in circuit boards, connectors, and housing materials to minimize fire-related failures and electrical malfunctions, enhancing both safety and longevity.

Consumer Products

Flame-retardant materials are also found in everyday consumer goods such as furniture, appliances, and electronics. For instance, flame-retardant materials in upholstered furniture and bedding help prevent ignition and slow down fire spread, providing an extra layer of safety in homes and workplaces.

Here are some common applications in the medical field, along with specific examples of devices and vacuum cast parts:

| Application | Examples |

| Prosthetic Components | Customized prosthetic limbs |

| Medical Enclosures and Housings | Casings for ECG machines, defibrillators |

| Custom Orthotics and Braces | Ankle braces, custom shoe insoles |

| Hearing Aid Components | Earmolds, inner casings |

| Dental Devices | Dental impression trays, orthodontic retainers |

| Respiratory Therapy Devices | Parts for nebulizers, oxygen concentrator components |

| Surgical Instruments and Tools | Endoscopic tools, scalpel handles, clamps |

Collaborate with 3D printing bureau to choose the best material and optimize build orientation for your project’s needs. Explore our 3D Printing Materials Guide to learn about various plastic and metal materials across technologies.

Discover more about additive manufacturing at projet.my. For assistance, reach out to our applications engineer at enquiry@projettech.com or try our instant quote for immediate pricing feedback.