Stereolithography (SLA) 3D printing is a widely used resin-based 3D printing process known for creating highly accurate, watertight prototypes and durable end-use parts. SLA printers deliver smooth surface finishes, intricate details, and a variety of advanced material properties, making them ideal for producing finely detailed and reliable components across various industries.

What Is Stereolithography (SLA) 3D Printing?

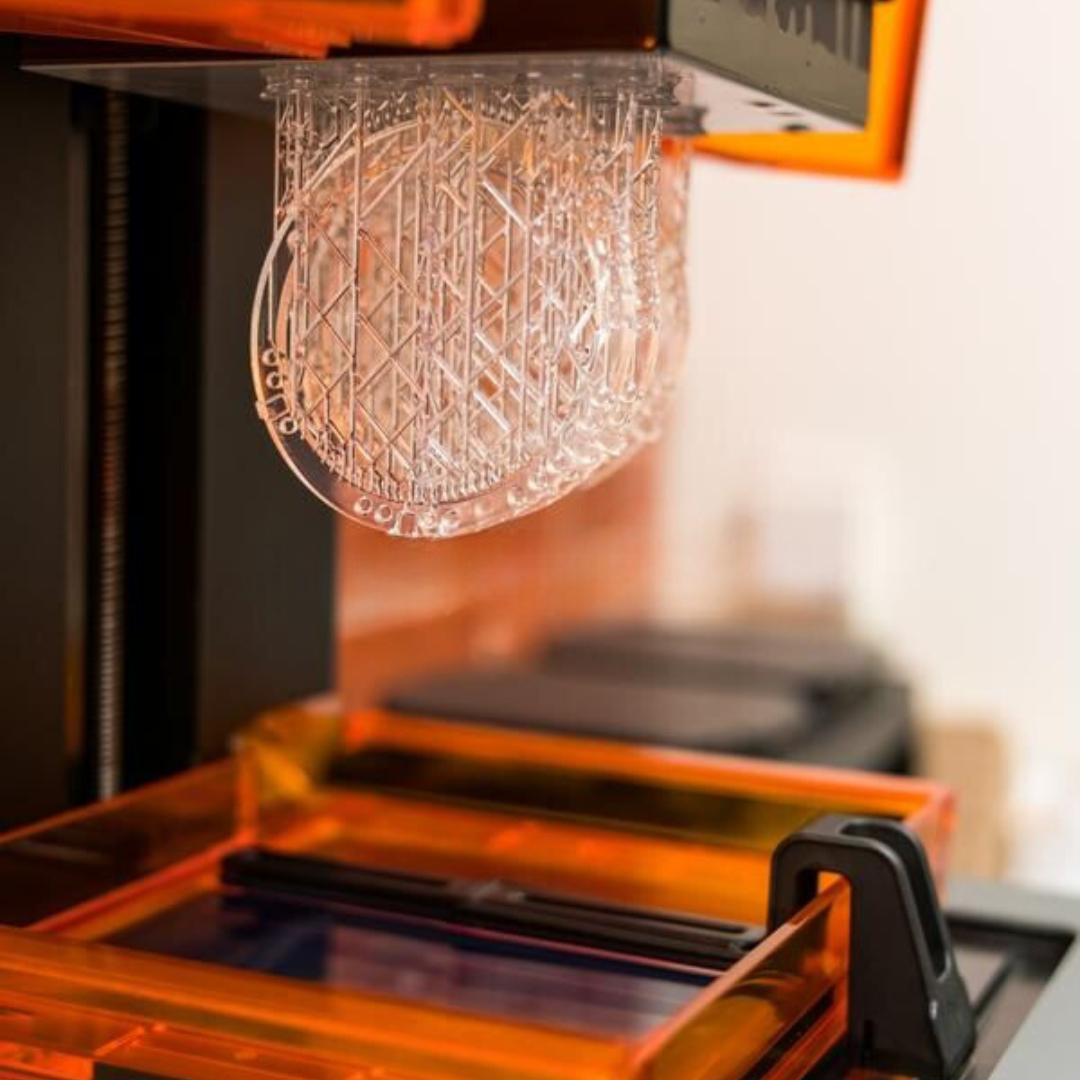

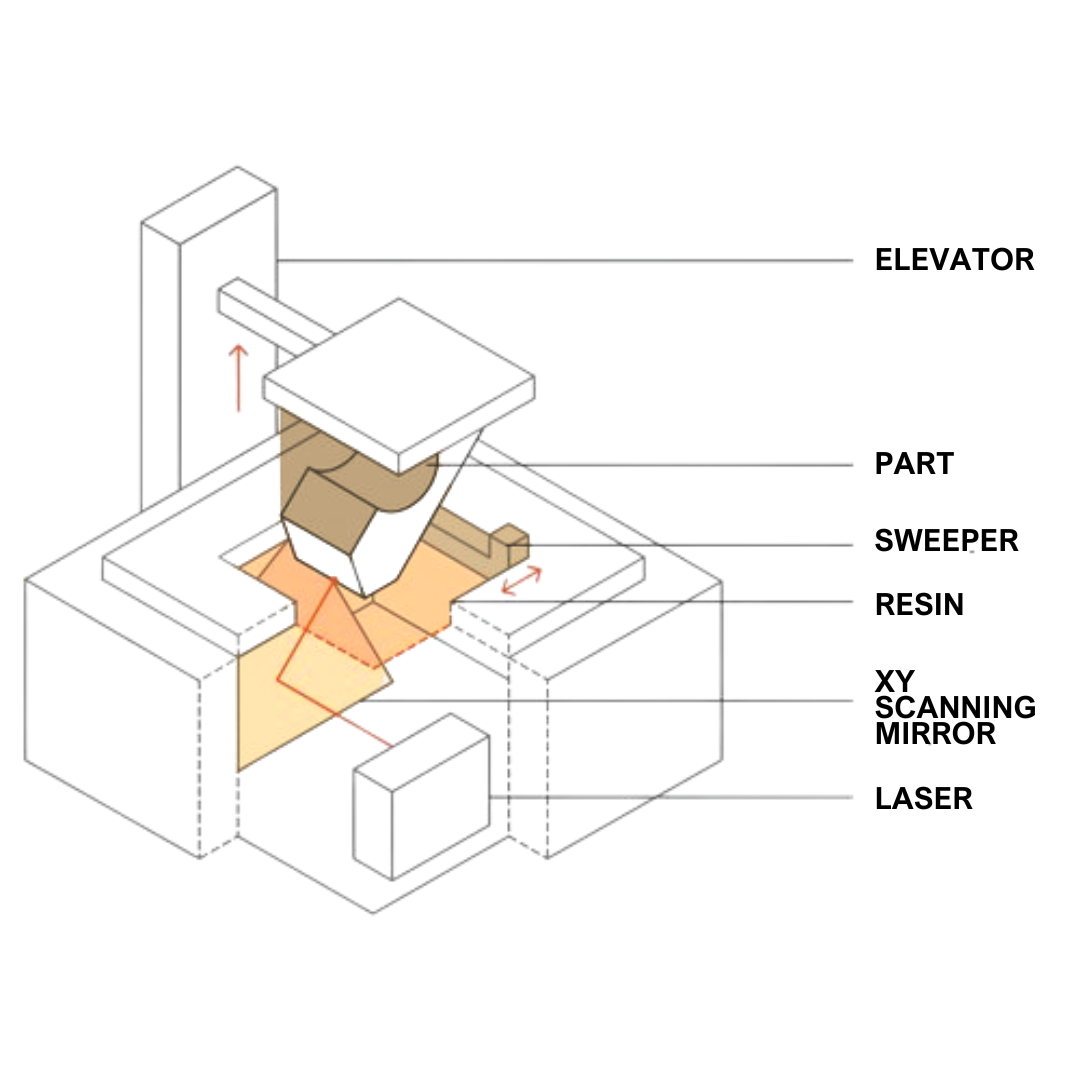

SLA (Stereolithography) is a 3D printing technique using a UV laser to solidify layers of photosensitive resin in a bath, forming the part upside-down layer by layer. As the build plate rises, the object appears to grow from the resin.

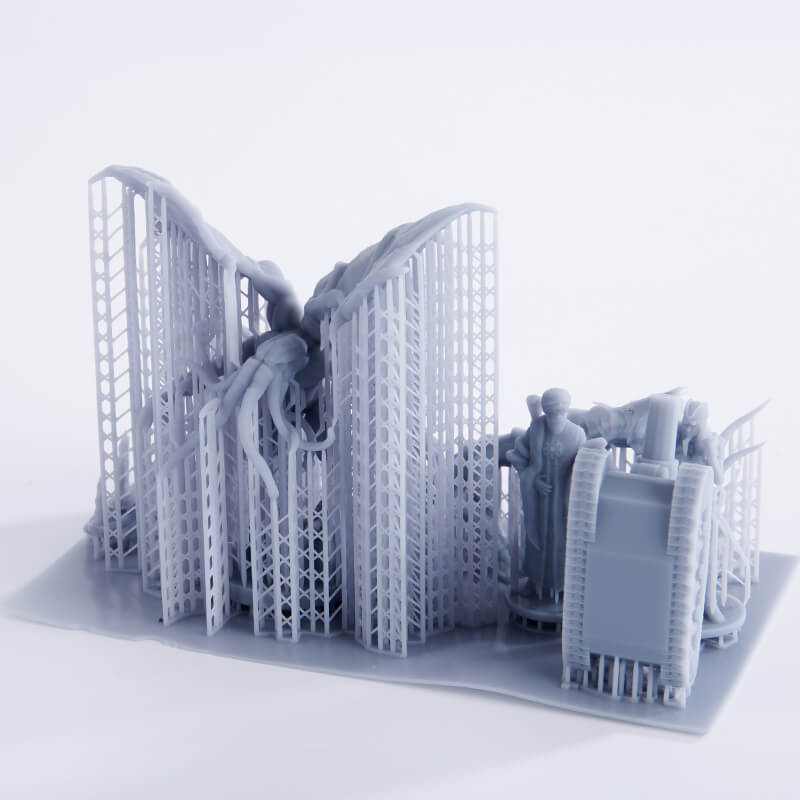

Supports play a crucial role in 3D printing by providing stability to overhanging sections of a model. Without them, these parts could sag, deform, or even fail during the printing process. By offering temporary structural reinforcement, supports ensure that the entire model prints successfully and maintains its intended shape until the print is complete. Post-printing, parts need UV exposure and an isopropyl alcohol wash for full curing.

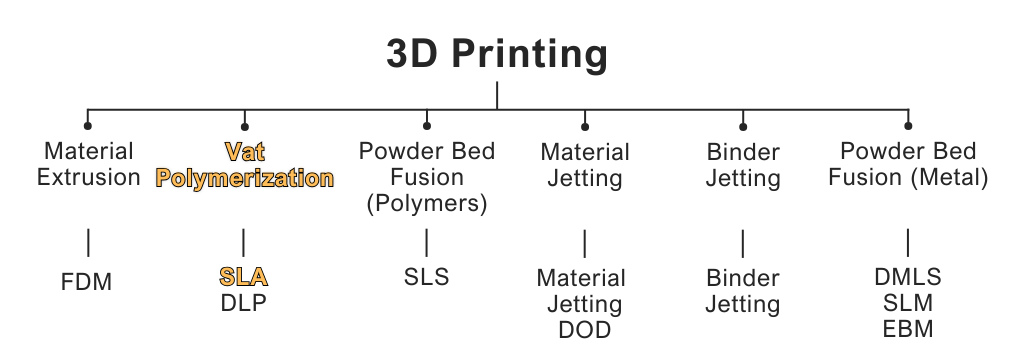

All 3 technologies use light to cure photopolymer resin:

- Stereolithography (SLA) uses UV lasers to selectively cure resin.

- Digital Light Processing (DLP) employs a digital projector to cure each resin layer.

- Liquid Crystal Display (LCD) uses an LCD screen to project targeted light patterns for curing.

SLA, a widely used vat photopolymerization technology, builds objects layer by layer by curing liquid polymer resin. It achieves this through an ultraviolet (UV) laser, which precisely solidifies each layer, eventually forming the complete object.

How Does an SLA 3D Printer Work?

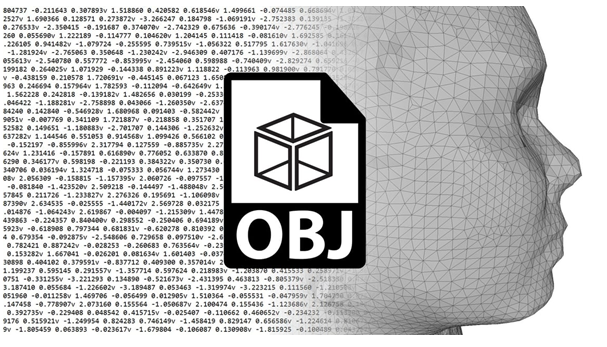

An SLA 3D printer uses a UV laser to cure liquid resin layer by layer. A 3D model is created with CAD software and sliced into thin layers.

The printer directs the UV laser to solidify resin selectively, building each layer on the previous one to complete the print.

3D Printing FDM , 3D Printing service Singapore , 3D Printing service KL, 3D Printing SLA, 3D Scanning Malaysia

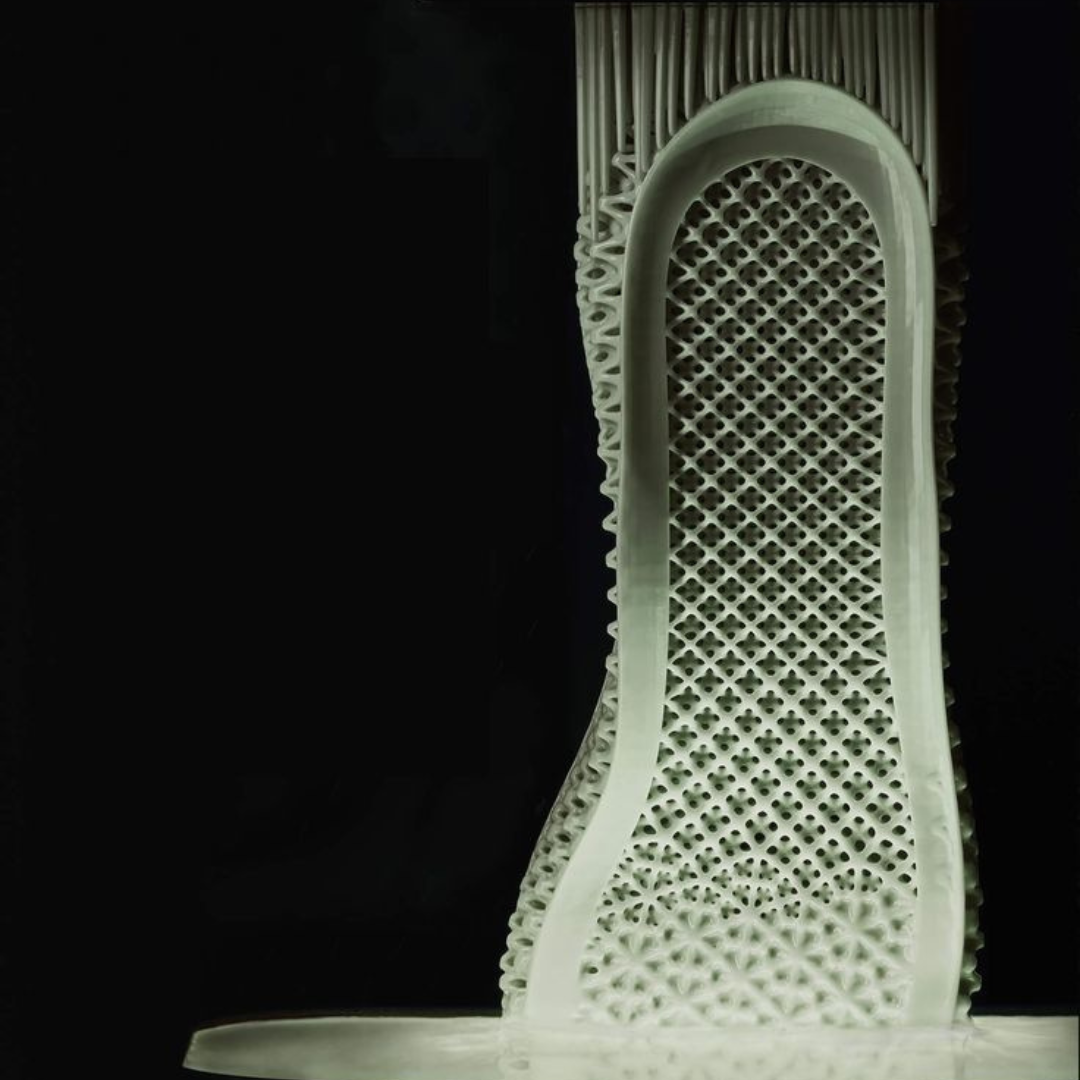

Support Structure Removal in 3D Printing

Support structures prevent the print from collapsing or deforming by providing temporary support.

After finishing a 3D printing job, the next step is to remove the support structures to unveil the completed part. This task is usually done by hand and requires careful attention to avoid damaging the final piece.

Next step post-processing steps. These steps can include sanding, polishing, or painting. These finishing touches refine the part’s appearance and performance, ultimately delivering a high-quality final product.

Brief History and Evolution of SLA Technology

SLA 3D printing, or stereolithography, was pioneered in the early 1980s by Chuck Hull, who introduced this transformative technology. Hull invented and named the process, filing its first patent in 1986. This innovation sparked a revolution in additive manufacturing, laying the foundation for various 3D printing techniques that continue to shape industries today.

3D Printing service malaysia

3D Printing service malaysia

Applications and Uses of SLA 3D Printing

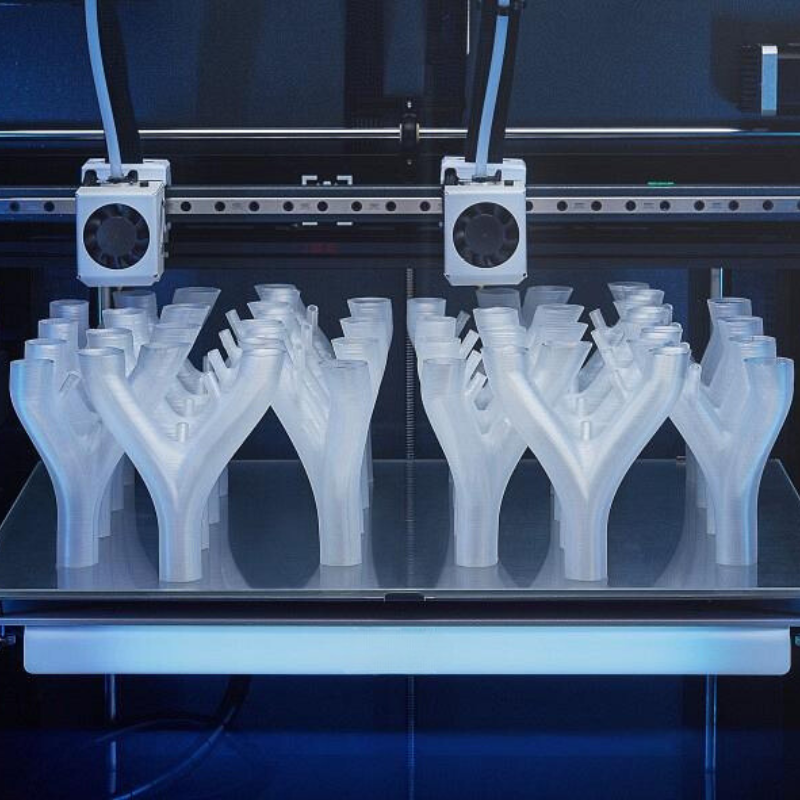

SLA 3D printing offers versatile applications across multiple industries:

- Prototyping: SLA printing produces precise models, ideal for engineering tests.

- Manufacturing: Creates functional parts suited for low-stress applications , Jig & Fixture .

- Engineering & Design: Hand-finished SLA parts make high-quality prototypes.

- Jewelry: Produces test models for jewelry designs.

- Dentistry: Manufactures dental models, soft tissues, and casting molds.

- Medical/Healthcare: Supports medical implant production with specialized materials.

- Aerospace: Create lightweight and intricate components for aircraft and spacecraft – from prototypes to tooling to end-use parts.

- Consumer electronics : Small electronic components, casings, and prototypes for consumer electronics devices

- Automotive : Rapid prototyping of vehicle components, including interior panels, engine parts, and prototype models.

- Sacrificial patterns: 3D printing is often used to create sacrificial patterns for metal casting tools, molds, and die casting.

What are the advantages of SLA 3D printing?

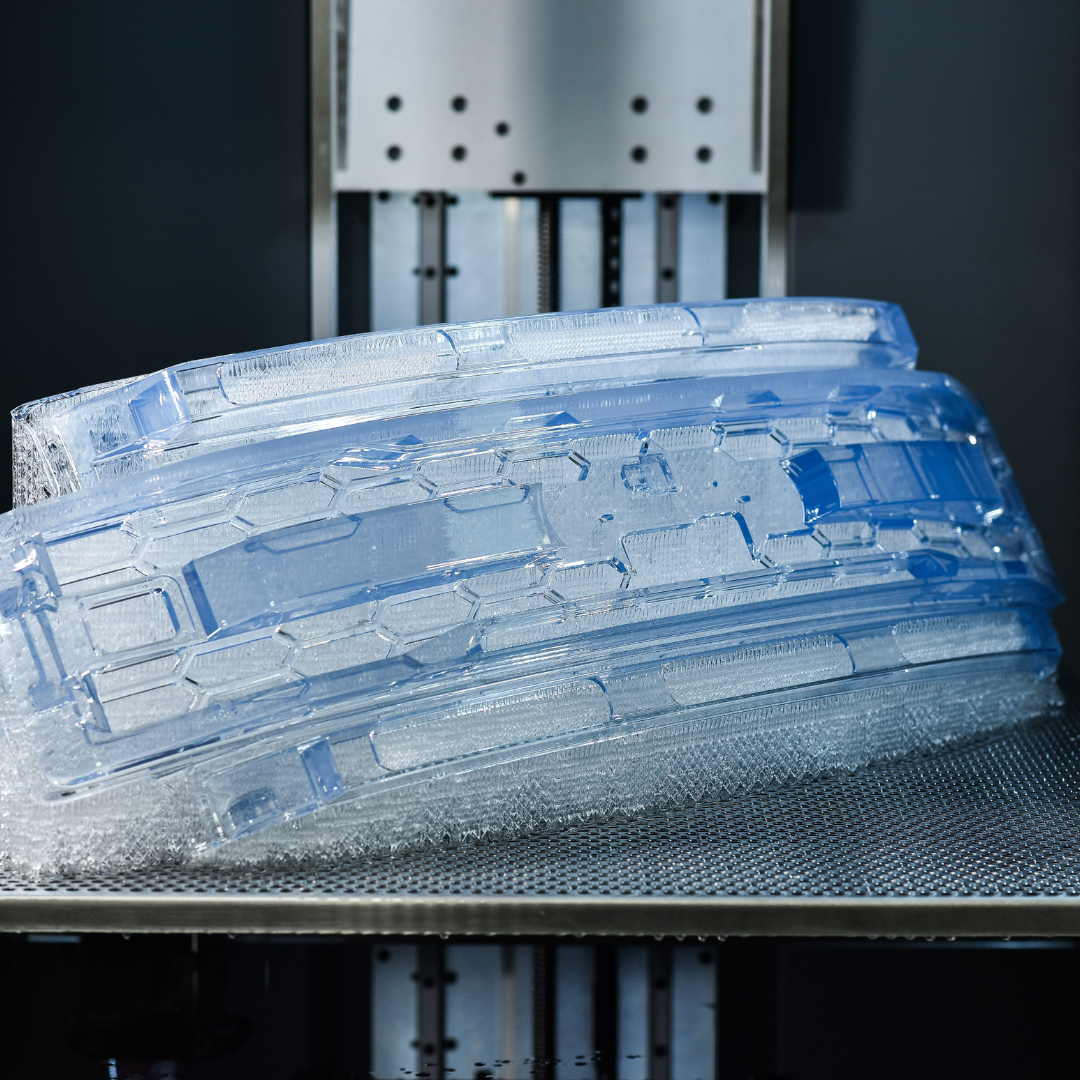

- High Dimensional Accuracy: SLA delivers precise, detailed parts with intricate features.

- Material Variety: Choose from specialty resins, like clear, flexible, and castable options.

- Reduced Waste: Liquid resin is efficiently used, with leftover material often reusable.

- Smooth Surface Finish: SLA-printed parts have exceptionally smooth surfaces, ideal for visual prototypes.

- Speed: SLA is among the fastest 3D printing methods, perfect for rapid prototyping and small-batch runs.

- Minimal Warping or Shrinkage: SLA printing maintains high dimensional accuracy with minimal distortion.

- High Resolution: SLA provides consistently high resolution across large prints, ensuring uniform quality.

Why Choose SLA 3D printing?

SLA 3D printing is growing in popularity for producing parts with exceptional detail, smooth surfaces, and high precision. This technology offers strong, versatile material options, making it a powerful choice for many applications beyond traditional manufacturing.With its ability to create highly accurate prototypes, SLA 3D printing is widely used in product development.

SLA 3D printing is a powerful tool for product development and small-batch production. Its ability to create highly accurate prototypes makes it indispensable for designers and engineers. Its perfect for manufacturing tools, casting molds, and functional parts in small quantities.

This versatility makes SLA 3D printing a valuable asset for a wide range of industries.

What Materials are Available for SLA 3D Printing?

Our 3D printing service provides a versatile selection of SLA materials that mimic the qualities of thermoplastics, making them perfect for a variety of applications. These SLA resins offer properties similar to ABS or PC plastics, with options that range from standard and tough to flexible and specialized types, including heat-resistant, biocompatible, and transparent resins.

Thanks to their high resolution and smooth finishes, SLA-printed parts are excellent for a broad range of uses.

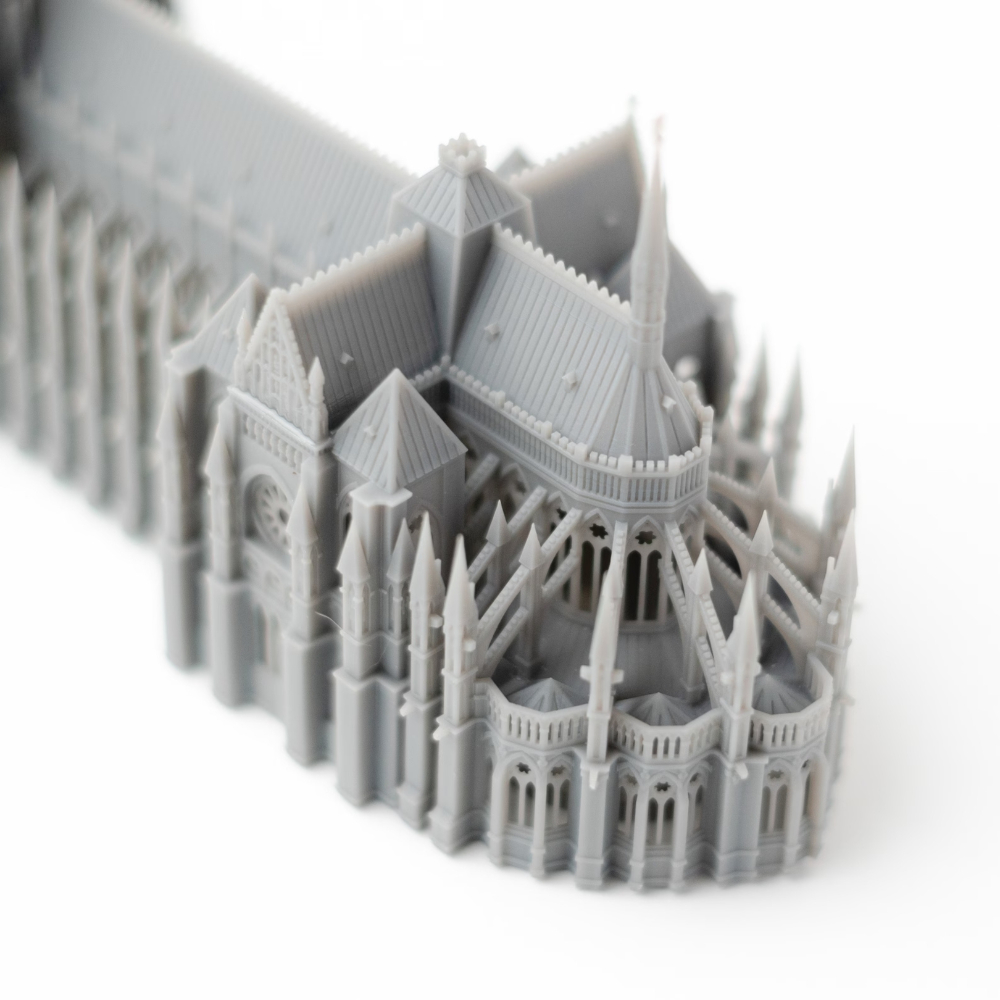

Image Gallery

Collaborate with 3D printing bureau to choose the best material and optimize build orientation for your project’s needs.Explore our 3D Printing Materials Guide to learn about various plastic and metal materials across technologies.

Discover more about stereolithography at projet.my. For assistance, reach out to our applications engineer at enquiry@projettech.com or +604-2858 335.