The Revolution of 3D Printing

3D printing, also known as additive manufacturing, is revolutionizing the industry, particularly in the realm of custom tooling and 3D-printed fixtures. Traditional fixture creation methods are often time-consuming and costly. However, with 3D printing technologies such as FDM, SLS, and SLA, manufacturers can directly print plastic and composite fixtures from CAD files. This innovation significantly streamlines the design-to-production process, resulting in substantial time and cost savings.

What are Fixtures in 3D Printing?

Fixtures play a crucial role in 3D printing as specialized tools that securely hold workpieces in precise positions during manufacturing processes such as welding, assembly, or inspection. Jigs guide cutting tools, while fixtures stabilize workpieces, ensuring they remain in position throughout the printing process. By maintaining consistency and accurate placement, fixtures facilitate the success of tasks involving multiple parts.

Types of Fixtures

When it comes to fixturing, manufacturers use several main types. These include assembly, inspection, marking, metrology, and welding fixtures.

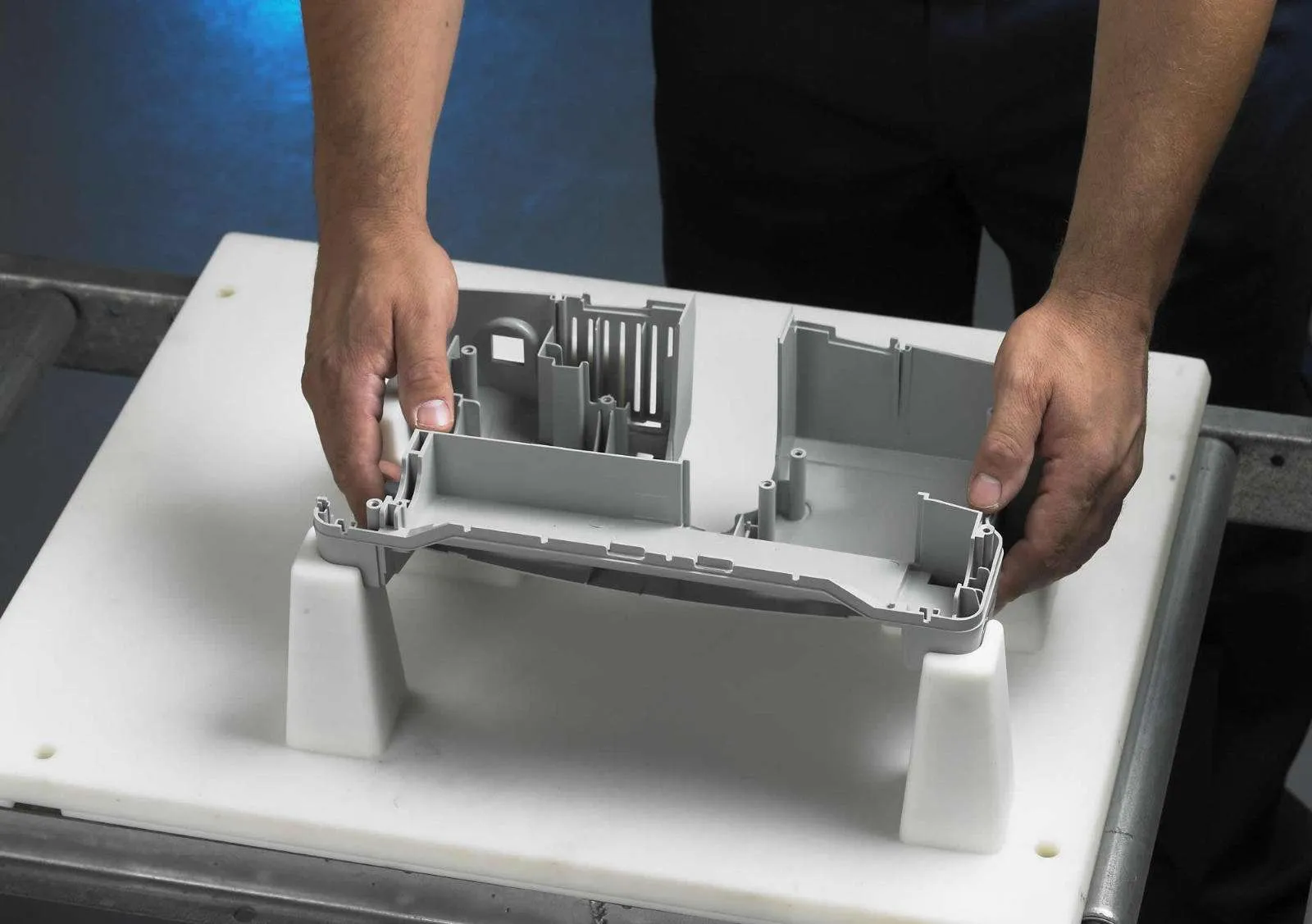

Assembly Fixtures:

Assembly fixtures play a critical role in accurately assembling components and products by securely holding parts in place to ensure precise fit and functionality during assembly. These fixtures offer numerous advantages, including faster assembly times, improved accuracy, reduced errors, and increased productivity. Widely utilized across industries such as automotive, appliance, electronics, and aerospace, assembly fixtures contribute to faster manufacturing processes and enhanced product quality.

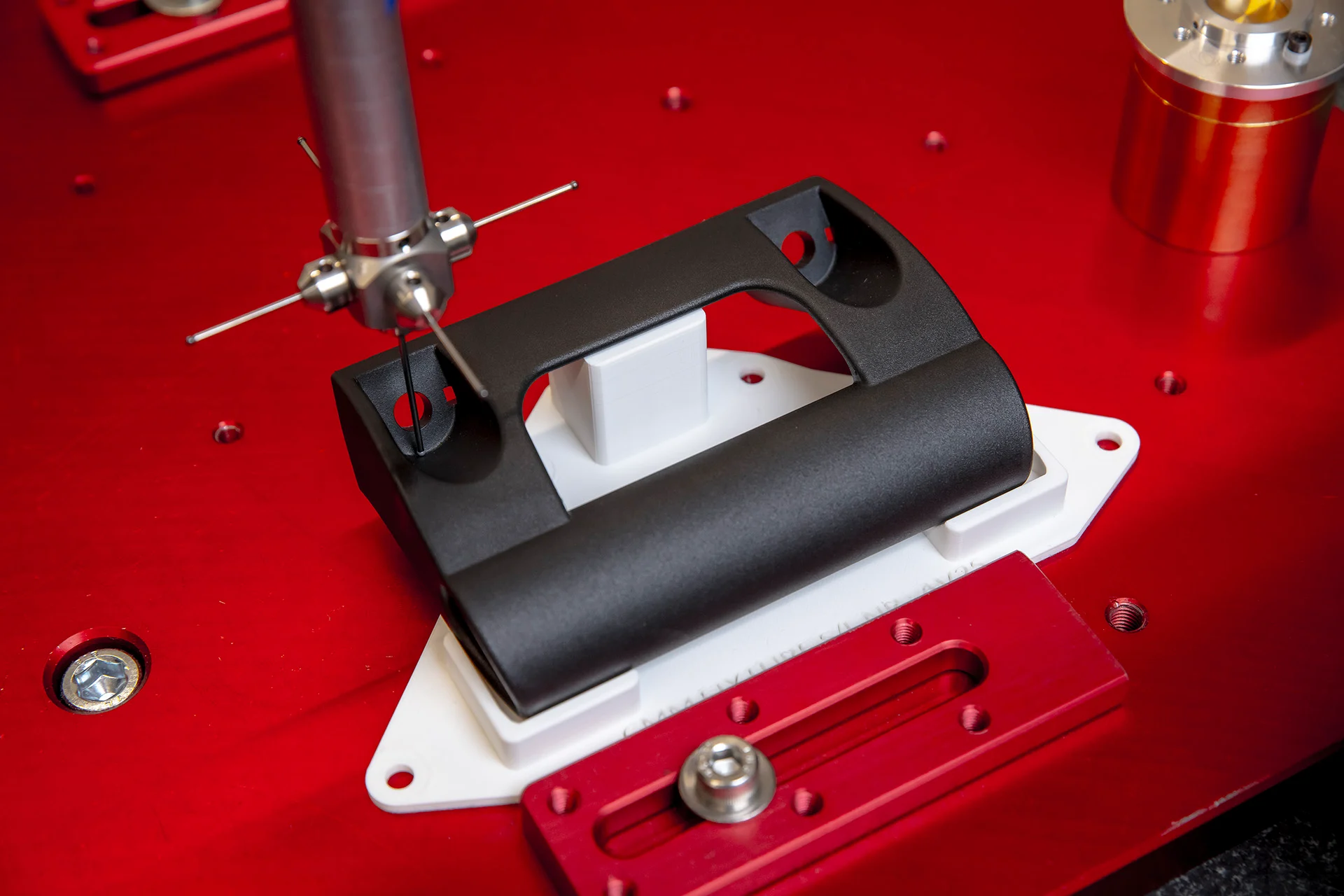

Metrology Fixtures:

Metrology fixtures, also known as coordinate machine measurement (CMM) fixtures, are essential tools for accurately measuring dimensions and performing other critical operations. These fixtures securely hold and position parts, probes, or workpieces during precision measurement tasks. Metrology, encompassing both practical and theoretical aspects, is the science of measurement.

Welding Fixtures:

Welding fixtures are essential tools in welding operations. They securely hold and position workpieces, ensuring stability and precise alignment for accurate welding. These fixtures significantly enhance weld quality, repeatability, and productivity across various industries including automotive, aerospace, construction, and metal fabrication.

Marking Fixtures:

Marking fixtures are integral to manufacturing processes, enabling precise and consistent marking on workpieces. They enhance the quality, efficiency, and repeatability of markings such as branding, serial numbers, product labeling, barcodes, and part identification. Laser marking fixtures, utilizing laser technology for precise and permanent marks, are particularly prevalent in industries such as aerospace, electronics, automotive, and metalworking. These fixtures play a crucial role in ensuring clear and durable identification and branding across various manufacturing applications.

Inspection Fixtures:

Inspection fixtures are specialized tools used in quality control to securely position and hold workpieces during inspection procedures, often in conjunction with a Coordinate Measuring Machine (CMM). These fixtures play a pivotal role in enhancing accuracy, repeatability, and efficiency throughout the inspection process. Widely utilized across industries such as aerospace, electronics, automotive, and precision manufacturing, inspection fixtures ensure reliable and consistent measurement outcomes.

Benefits of 3D Printed Fixtures:

- Reduced Lead Times: 3D printing drastically cuts lead times. It’s much faster than traditional tooling. Parts can go from a CAD file to a finished tool in hours or days, rather than weeks or months. This translates to faster production ramp-up and quicker time-to-market for new products.

- Lower Costs: There are no minimum orders, expensive tools, storage, or machining. Even single-use prototypes are affordable. On-demand printing eliminates the need for inventory, further reducing expenses. This makes 3D-printed fixtures ideal for low-volume production runs.

Rapid Prototyping and Iteration: You can make design changes fast. Just edit the file and reprint the fixture. This eliminates the need for extensive rework, enabling rapid prototyping and design iterations. We can explore more design ideas in less time. This will lead to better product development.

- Customization: 3D printing allows for custom tools. They can be for unique parts or processes. The tools include design-for-manufacturing from the start. Also, internal shapes can be complex. They can include moving parts. These parts optimize alignment and speed integration. 3D printing can make jigs for rare, obsolete, or unique parts. Traditional machining struggles with these parts.

Summary

Projet considers 3D printing service as a key factor to the success of fast adoption of AM in manufacturing, We offer a range of capabilities, including 3D printing technologies such as FDM, SLA, and SLS, along with various solutions like rapid prototyping, mechanical design, and reverse engineering. We eagerly anticipate the opportunity to support your company in its processes.

Connect with Projet:

If you’ve had a positive experience with Projet that you’d like to share, please reach out to us at enquiry@projettech.com. We eagerly anticipate hearing from you.

For additional information, visit our website for comprehensive details about our services and contact information. Our friendly team is ready to assist you at any time.