How 3D Printing Solves FMCG’s Biggest Challenges

The global FMCG market is projected to hit $15.3 trillion by 2025, growing at 5.4% annually. In this fast-paced, trend-driven industry, standing out means staying ahead of shifting consumer demands—while balancing cost, innovation, and sustainability.

Enter 3D printing: a game-changer that accelerates product development, enables hyper-customization, cuts costs, and reduces environmental impact—all at once. For FMCG brands, it’s not just an advantage—it’s the future.

That’s where 3D printing comes in.

Also known as additive manufacturing, 3D printing constructs items through precise material layering based on digital blueprints. While the technology itself isn’t new, its recent democratization has sparked a paradigm shift—particularly in fast-moving consumer goods, where speed and customization are critical. By embracing 3D printing, FMCG companies can accelerate innovation, enhance product customization, cut costs, and reduce environmental impact, ensuring they remain competitive in an ever-evolving market.

The Benefits of 3D Printing for FMCG:

3D printing can offer many benefits for FMCG companies, such as:

- Rapid Prototyping and Product Development :

3D printing enables FMCG companies to quickly create prototypes and iterate on designs. This accelerates the product development cycle, allowing companies to bring new products to market faster. For instance, Coca-Cola used 3D printing to prototype bottle.

– Reducing Time-to-Market: By quickly creating prototypes, teams can accelerate the development process, allowing products to reach the market faster than traditional development methods.– Enabling More Iterations and Refinements: Rapid prototyping allows for rapid iteration and refinement of product designs based on feedback, enabling teams to explore multiple ideas and approaches before finalizing the design.

– Testing and Validating Product Concepts and Functionalities Efficiently: Prototypes provide a tangible representation of the product, allowing teams to test and validate concepts and functionalities early in the development process. This helps identify potential issues and make necessary adjustments before investing significant resources in full-scale production.

- Customization and Personalization :

FMCG companies can leverage 3D printing to offer customized and personalized products to consumers. This includes:– Personalized Packaging: Creating unique packaging tailored to individual consumer preferences or special occasions.

– Custom Products: Producing bespoke products that meet specific consumer requirements, enhancing customer satisfaction and loyalty.

- Complex Geometries :

FMCG companies can now design and manufacture intricate shapes and functionalities that were previously impossible with traditional methods. This capability enhances product differentiation and allows brands to stand out in crowded markets.For instance, Chanel utilized 3D printing to craft a distinctive mascara brush that provides enhanced volume and definition to lashes, showcasing the technology’s potential for innovation in the beauty industry.

- Sustainability:

FMCG companies can delve into eco-friendly 3D printing materials, thereby minimizing waste in contrast to conventional manufacturing methods. For instance, Mango embraced 3D printing to fashion a line of jewellery pieces utilizing sustainable materials, showcasing the technology’s capacity to promote environmental responsibility within the fashion industry.

- On Demand Production:

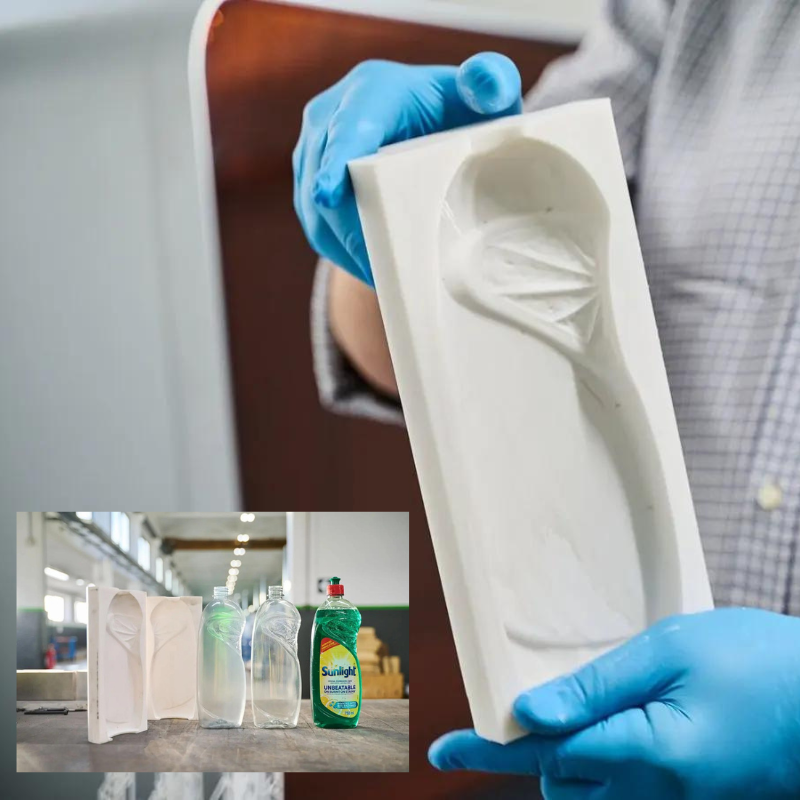

On-demand Production: FMCG companies can diminish their dependence on large production runs and mitigate inventory costs by manufacturing products closer to demand using 3D printing. For instance, Unilever employed 3D printing to fabricate on-demand molds for its Sunlight dishwashing liquid bottles, exemplifying how this technology enables agile and efficient production processes within the FMCG sector.

Comparison of 3D Printing Processes

| TECHNOLOGY | FDM | SLA | SLS | SLM | PµSL | MJF |

| Build size | W500 x L500 x H500 mm | W600 × L350 × H350 mm | W350 X L350 X H590mm | W150 X L150 X H150mm | W100 X L100 X H50mm | W350 X L350 X H590mm |

| Best lead time | 2day | 2day | 4day | 5day | 5day | 6day |

| Dimensional accuracy | ± 0.3mm or lower | ± 0.3mm or lower | ± 0.3mm or lower | ± 0.3mm or lower | ± 0.2mm or lower | ± 0.3mm or lower |

| Prototyping applications | Proof-of-concept prototypes from a wide range of materials. | Highly detailed visual prototypes. | Functional prototypes for testing and usability evaluations. | Metal prototypes with complex geometries. | Functional parts with small features and significant complexity. | High-fidelity functional parts for rigorous testing. |

| End-use applications | Non-visual end parts, including precision jigs and fixtures. | Small aesthetic, non-functional end parts. | Functional end-use components. | Fully functional complex metal components. | Functional parts. | Functional end-use components. |

Connect with Projet:

If you’ve had a positive experience with Projet that you’d like to share, please reach out to us at enquiry@projettech.com. We eagerly anticipate hearing from you.

For additional information, visit our website for comprehensive details about our services and contact information. Our friendly team is ready to assist you at any time.