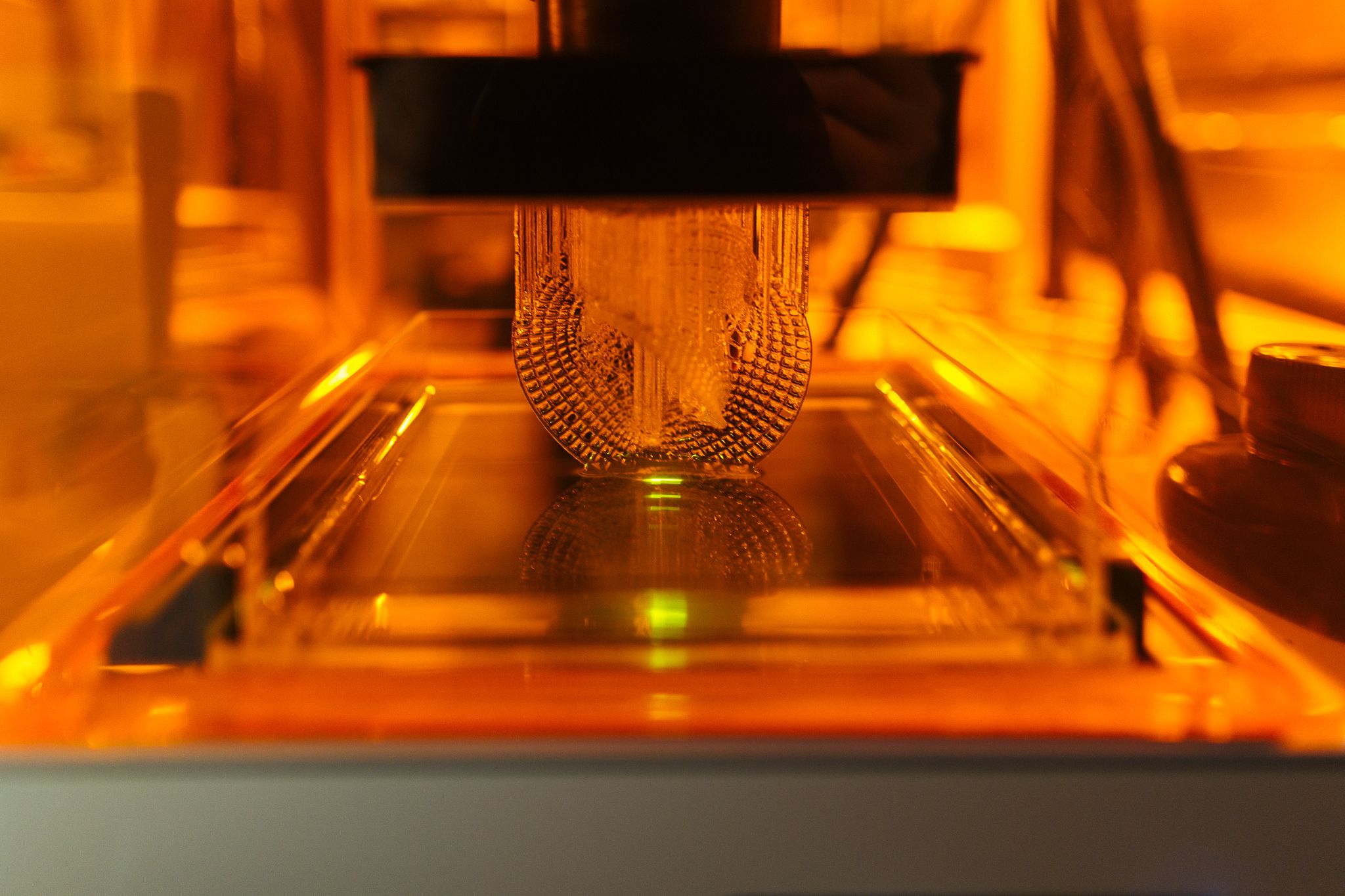

Resin 3D printing, also known as vat polymerization, stands as a cutting-edge technology in additive manufacturing. Renowned for its capability to create intricate objects with precision, it remains a top choice for applications requiring high resolution.

Two primary technologies, stereolithography (SLA) and digital light processing (DLP), dominate the realm of resin printing. Despite both employing photopolymer resin, their distinction lies in the light source and curing method utilized to construct 3D objects layer by layer.

Stereolithography (SLA):

SLA uses a focused laser to cure the resin layer by layer. It achieves great precision and smooth surface finishes. SLA printers can make intricate details. They can also make complex shapes.

Digital Light Processing (DLP):

DLP printers use a projector with a high-res image. It cures a whole resin layer at once. This method offers faster printing times than SLA. But, it may result in slightly less defined details.

Resolution:

In the past, SLA outperformed DLP in terms of resolution. However, advancements in projection technology have made DLP comparable to SLA. SLA printers typically offer larger build volumes without compromising print resolution.

Surface Finish:

SLA printers use laser tracing outside contours, resulting in excellent detail. The minimum feature size is determined by the size of the laser spot, typically ranging from 0.03 mm to 0.15 mm. SLA printers tend to produce smoother parts compared to DLP printers, which may exhibit a pixelated effect on complex surfaces.

Accuracy:

Both SLA and DLP processes boast the highest deposition accuracy among 3D printing methods. However, for parts intended for medical or mechanical applications, SLA-printed parts usually require post-processing to ensure optimal mechanical properties.

Advantages of SLA Compared to DLP:

- Smoother Surfaces: SLA parts typically exhibit smoother surfaces compared to those produced by DLP printers. This is particularly evident on curved surfaces, where SLA achieves a higher level of detail and smoothness.

- Larger Build Volumes: SLA printers can have larger build volumes. They do not lose print resolution. This means SLA can make large parts with high precision and detail. This makes it good for a wider range of uses needing big parts.

Summary

Projet considers 3D printing service as a key factor to the success of fast adoption of AM in manufacturing, We offer a range of capabilities, including 3D printing technologies such as FDM, SLA, and SLS, along with various solutions like rapid prototyping, mechanical design, and reverse engineering. We eagerly anticipate the opportunity to support your company in its processes.

Connect with Projet:

If you’ve had a positive experience with Projet that you’d like to share, please reach out to us at enquiry@projettech.com. We eagerly anticipate hearing from you.

For additional information, visit our website for comprehensive details about our services and contact information. Our friendly team is ready to assist you at any time.