What is difference between jigs & fixtures?

Are you confused about the difference between jigs and fixtures? These two terms are often used together, but they are not interchangeable despite their similar functions. Let’s explore the subtle differences between these manufacturing tools and understand how they enhance manufacturing quality, reduce production costs, and facilitate automation.

Key Differences Between Jigs and Fixtures:

While both jigs and fixtures are essential in manufacturing, their primary functions and characteristics differ significantly:

- Function:

Jigs: Guide the cutting tool.

Fixtures: Hold the workpiece. - Mobility:

Jigs: Generally mobile & can be easily positioned.|

Fixtures: Usually stationary & fixed to the machine. - Tool Involvement:

Jigs: Often involve the cutting tool in their operation.

Fixtures: Do not interact with the cutting tool directly. - Complexity:

Jigs: Can be more complex due to the need to guide the tool.

Fixtures: Simpler in design as their primary role is to hold the workpiece.

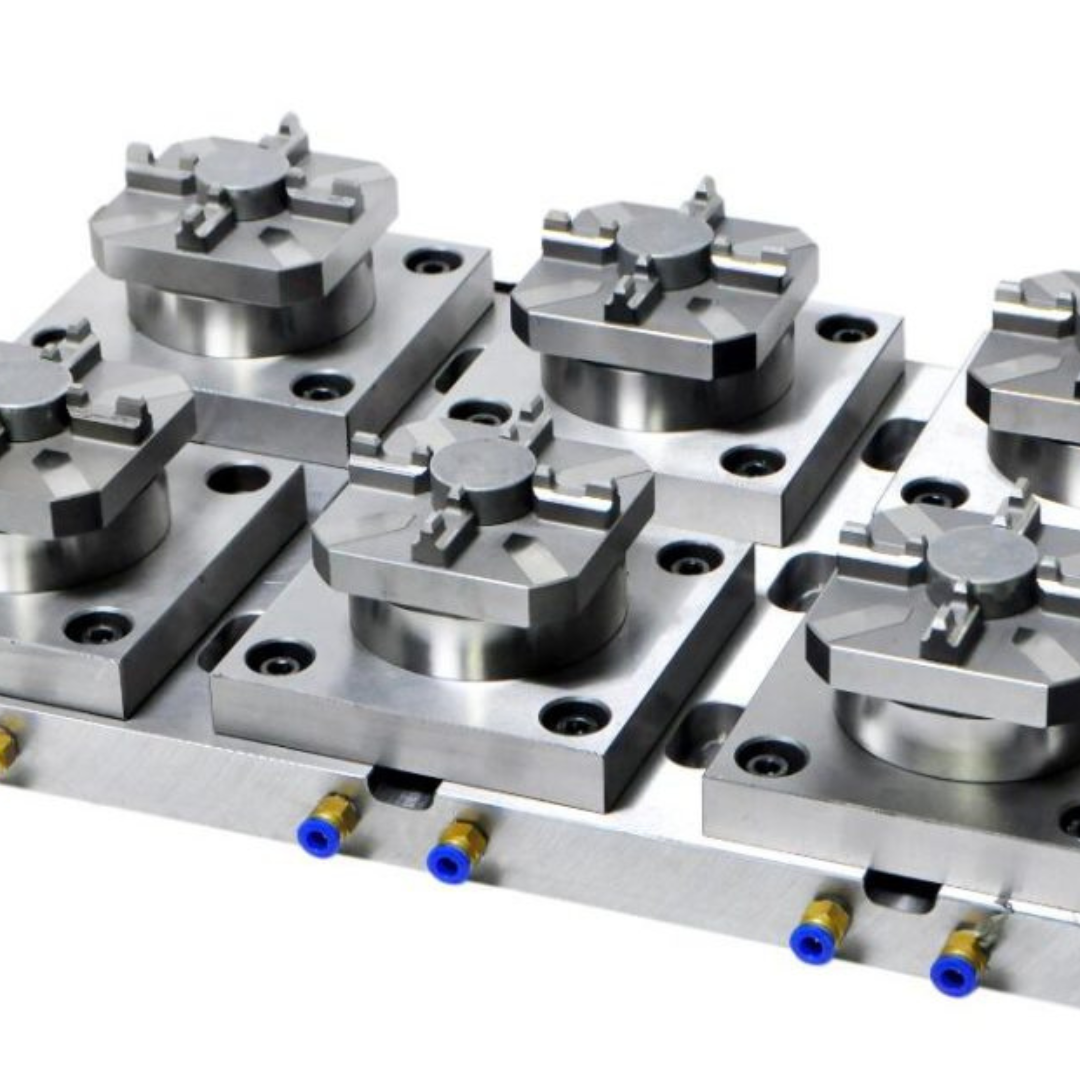

Fixtures

So, how does a fixture differ from a jig? While jigs guide manufacturing tools, fixtures hold a workpiece in a secure position, orientation, or location. For example, at Projet, a fixture is used to clamp a block of raw material inside a CNC machine. Similarly, the vice on your workbench is also a fixture.

Key Characteristics of Fixtures:

- Stability: Fixtures provide a stable and immovable base for the workpiece.

- Customization: They are often custom-made to fit specific workpieces and machining tasks.

Common Uses of Fixtures:

- Milling Fixtures: Hold the workpiece securely during milling operations.

- Turning Fixtures: Ensure the workpiece is stable during lathe operations.

- Grinding Fixtures: Keep the workpiece steady during grinding processes.

Jigs

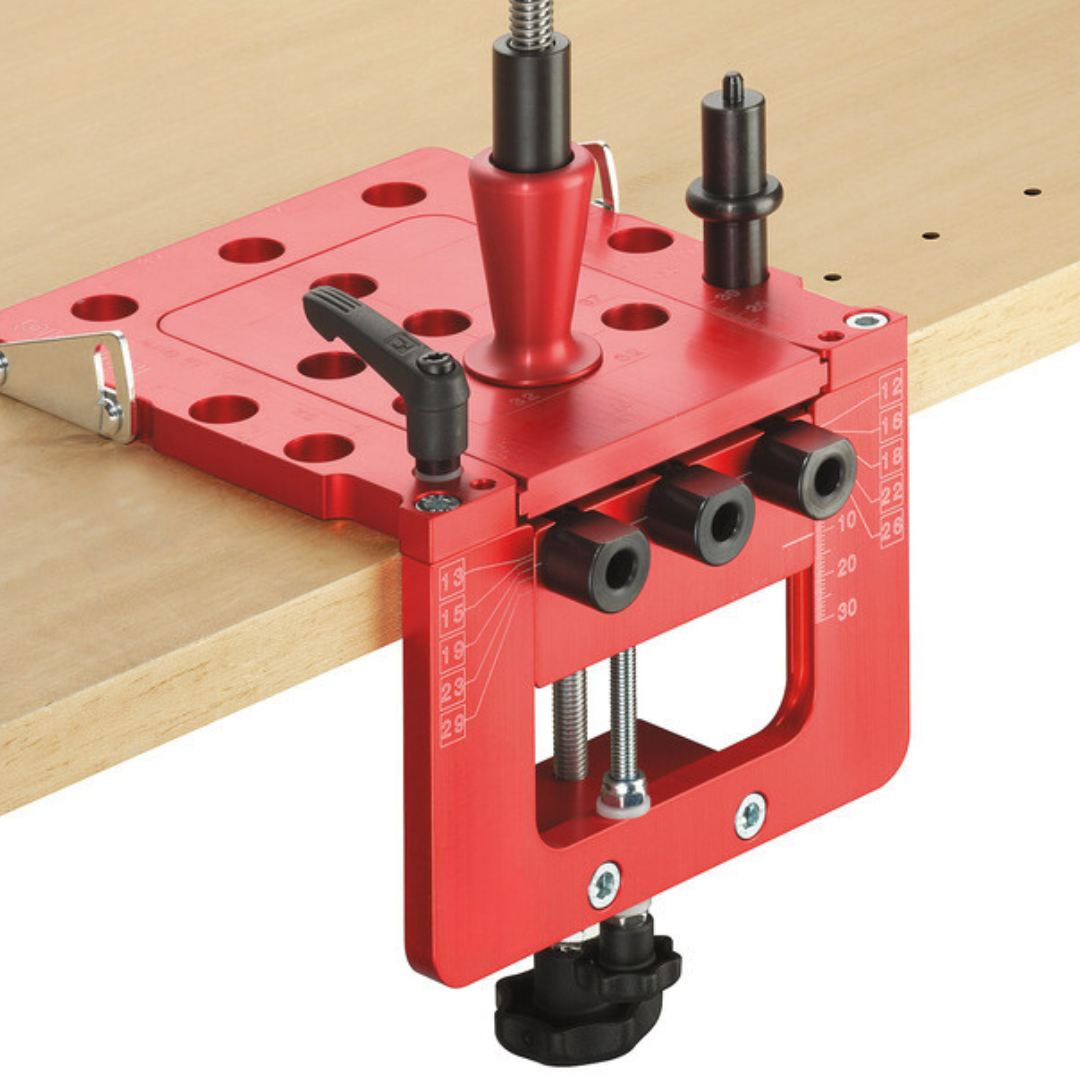

While you might associate the term “jig” with your weekend fishing hobby, it has a distinct meaning in the engineering world. In manufacturing, a jig holds a tool in position to perform a specific task, often ensuring accuracy and repeatability when drilling and tapping holes.

Key Characteristics of Jigs:

- Guidance: Jigs guide the tool, ensuring that the machining process is accurate.

- Tool Support: They often provide support to the cutting tool, enhancing stability and precision.

Common Uses of Jigs:

- Drilling Jigs: Used to guide the drill bit and ensure holes are drilled at the correct location and angle.

- Reaming Jigs: Ensure precise enlargement of holes to exact dimensions.

Type of Application of 3D Printed Parts

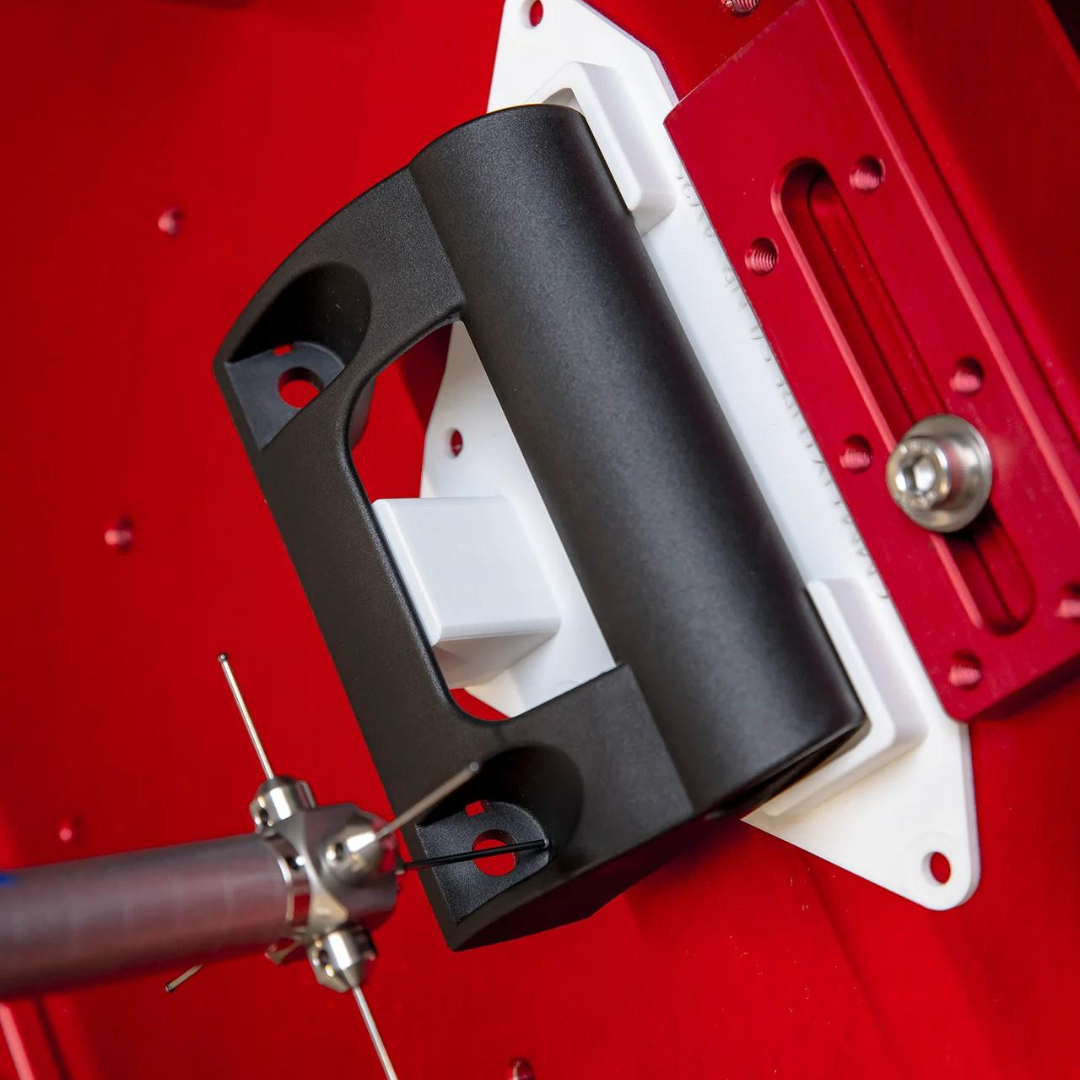

- Inspection fixtures : Specific equipment or tools that are utilized in quality control to position and hold workpieces in place

- Metrology fixture : Fixtures for co-ordinate measuring machines (CMM)

- Marking fixtures : Fixtures are implemented in manufacturing processes to create accurate and consistent marking on workpieces.

- Welding fixtures: Tools or equipment used in the welding processes to hold and position workpieces during welding.

- Assembly fixtures : Fixture design positions and holds parts during assembly, ensuring that the part accurately fits and functions properly

- Drill guide jig : Drill guide bushings are available in two types: press-fit and screw-in. Those designed specifically for use in plastics work best and significantly improve productivity in production.

- Go/No Go Gauges : 3D printed go/no-go gauges are invaluable for determining a part’s successful function when small differences in form and dimension are critical. These gauges are particularly useful when those dimensions cannot be easily or quickly assessed using calipers.

- Assembly jig: 3D printing custom assembly jigs reduces cycle times, enhances ergonomic workflows for assembly technicians, and improves consistency across production units.

Connect with Projet:

If you’ve had a positive experience with Projet that you’d like to share, please reach out to us at enquiry@projettech.com. We eagerly anticipate hearing from you.

For additional information, visit our website for comprehensive details about our services and contact information. Our friendly team is ready to assist you at any time.