Why Tooling Matters

Tooling comes in all shapes and sizes—from jigs and fixtures to end-of-arm tools (EOAT). The right tooling helps your team work efficiently, improve product quality, and hit production targets. But designing, sourcing, and manufacturing custom tools with traditional methods can be expensive, slow, and limiting.

With additive manufacturing (3D printing)—a solution that allows you to create the tooling you need quickly, affordably, and with unprecedented design freedom.

Common Tooling Challenges

Traditional tooling often comes with hurdles that can slow production and inflate costs:

High Costs – Custom tools, especially complex designs, can be expensive to machine. CNC milling or outsourcing adds up quickly.

Long Lead Times – Waiting weeks for a tool can halt production and delay projects.

Design Limitations – Conventional machining forces compromises in shape, ergonomics, and functionality.

Inventory Management – Rarely used tools take up valuable storage space and can become obsolete.

Skilled Labor Shortages – CNC operators and skilled machinists are in high demand, limiting internal capacity.

Let’s explore how additive manufacturing solves each of these challenges.

Challenge 1: High Costs of Traditional Tooling

Machining complex fixtures or soft jaws can be costly, especially for low-volume or one-off projects. Additive manufacturing changes the economics by enabling cost-effective, low-volume production with no geometric constraints. You can create lightweight, ergonomic, and highly functional tooling at a fraction of the cost of traditional methods.

Example:

Few company reduced fixture costs and lead times by ~80% using 3D printing instead of machining, allowing them to offer more competitive injection molding services.

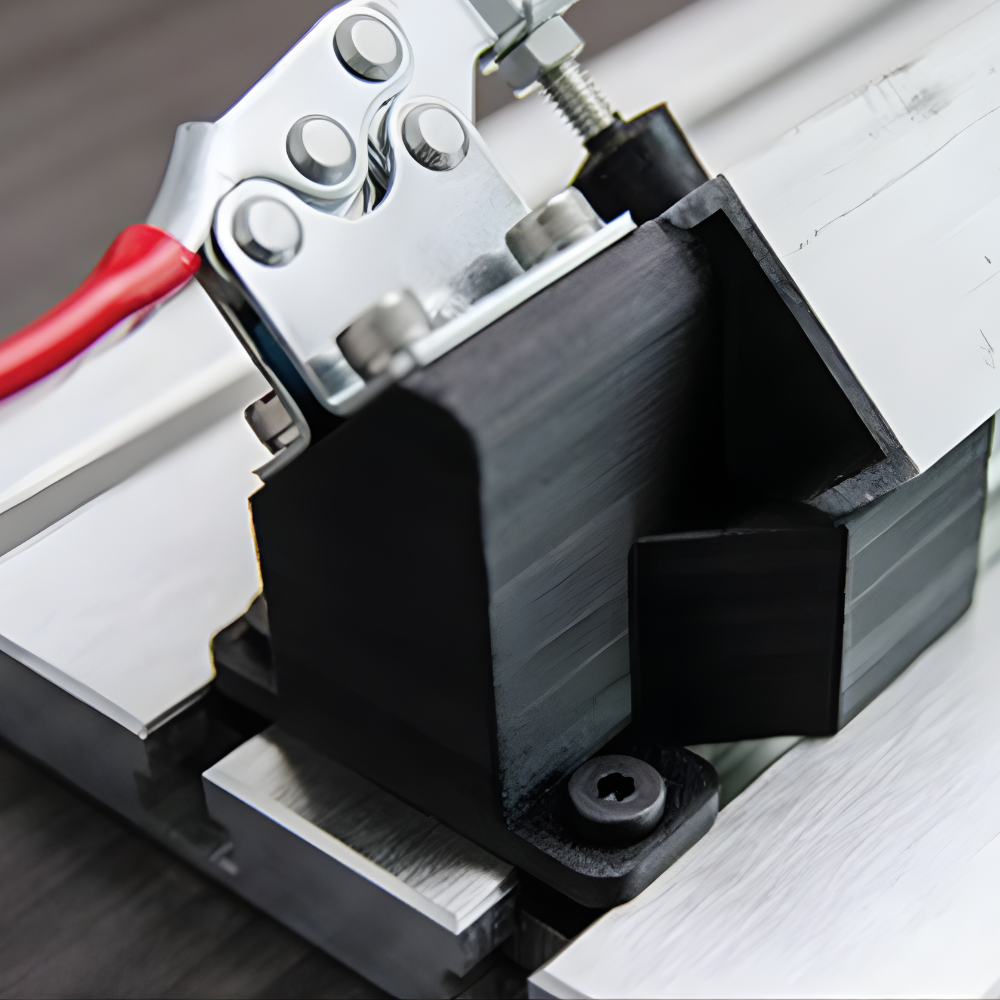

They leverages FDM 3D printing to produce workholding fixtures that traditional machining couldn’t achieve.

Challenge 2: Long Lead Times

Traditional tooling can take weeks or even months to manufacture. Delays stall production and impact revenue.

Solution: Print EOATs and custom jigs in-house. A 3D printer can produce tools overnight, letting engineers quickly iterate designs and maintain production schedules.

Example: Custom end-of-arm tooling for robotics can now be designed, printed, and deployed faster than ever, cutting weeks off the project timeline.

Challenge 3: Design Limitations

Machining constraints often force designers to make “good enough” tools instead of optimal ones. Traditional tooling may be heavy, awkward, or less ergonomic.

Solution: Additive manufacturing removes these constraints, enabling complex geometries, lightweight structures, and ergonomic designs. Tools can be customized to fit the user, the task, or the workflow perfectly.

Example:

Prints custom jigs to reduce worker strain, improving productivity and safety:

~65% reduction in process time

300% increase in productivity

~85% cost savings vs. outsourcing

Challenge 4: Inventory Management

Rarely used jigs and fixtures occupy expensive storage space, and disposal can be a hassle.

Solution: Store digital files instead of physical tools. With 3D printing, you can maintain a digital inventory and print tools on demand.

Example:

Medtronic stores digital designs for medical gauges and fixtures, saving space and eliminating physical storage costs while still producing tools when needed.

3D Printing Service Malaysia , 3D Printing service Singapore , 3D Printing service KL , 3D Printing service Selangor, 3D Scanning Malaysia

Key Benefits of Additive Manufacturing for Tooling

Additive manufacturing provides measurable advantages for modern tooling:

Cost Efficiency – Lower production costs, especially for low-volume, complex parts.

Short Lead Times – Rapid production of custom tools and fixtures.

Design Freedom – Create optimized, ergonomic, lightweight tooling.

Lower Barrier to Entry – No need for highly specialized CNC equipment or complex setups.

Scalability – Print one tool or a batch without extra setup costs.

From jigs and fixtures to end-of-arm tools and investment casting master patterns, 3D printing enables faster, cheaper, and smarter production aids.

Real-World Applications

Injection Molding Fixtures – Faster, more affordable fixtures allow competitive pricing.

Robotics EOAT – Custom end-of-arm tools designed and printed overnight.

Medical Devices – Sterilizable jigs and gauges stored digitally.

Military and Aerospace – Lightweight, ergonomic tooling for field and production use.

3D printing isn’t just for prototypes. It’s a strategic solution for tooling, helping manufacturers save money, reduce lead times, and produce optimized, ergonomic tools. By leveraging additive manufacturing, businesses can focus on value-added work, improve efficiency, and stay ahead of the competition.

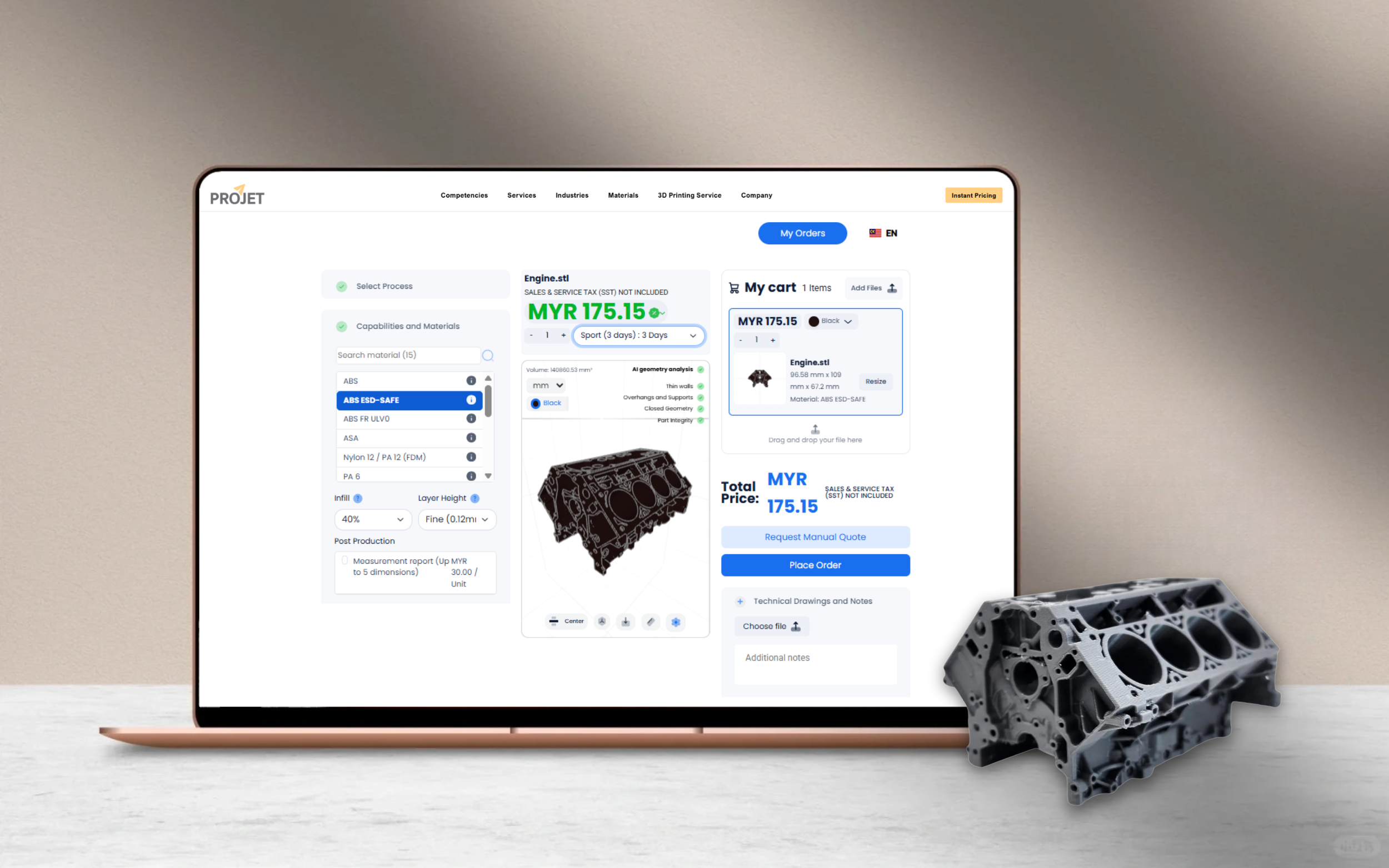

3D Printing Services

Instant Price