3D scanning is revolutionizing reverse engineering by creating highly accurate digital models of physical objects. This advanced technology simplifies the process of analyzing, replicating, and improving existing designs, leading to faster product development and greater innovation. With 3D scanning, businesses can achieve unmatched precision and efficiency in their reverse engineering projects.

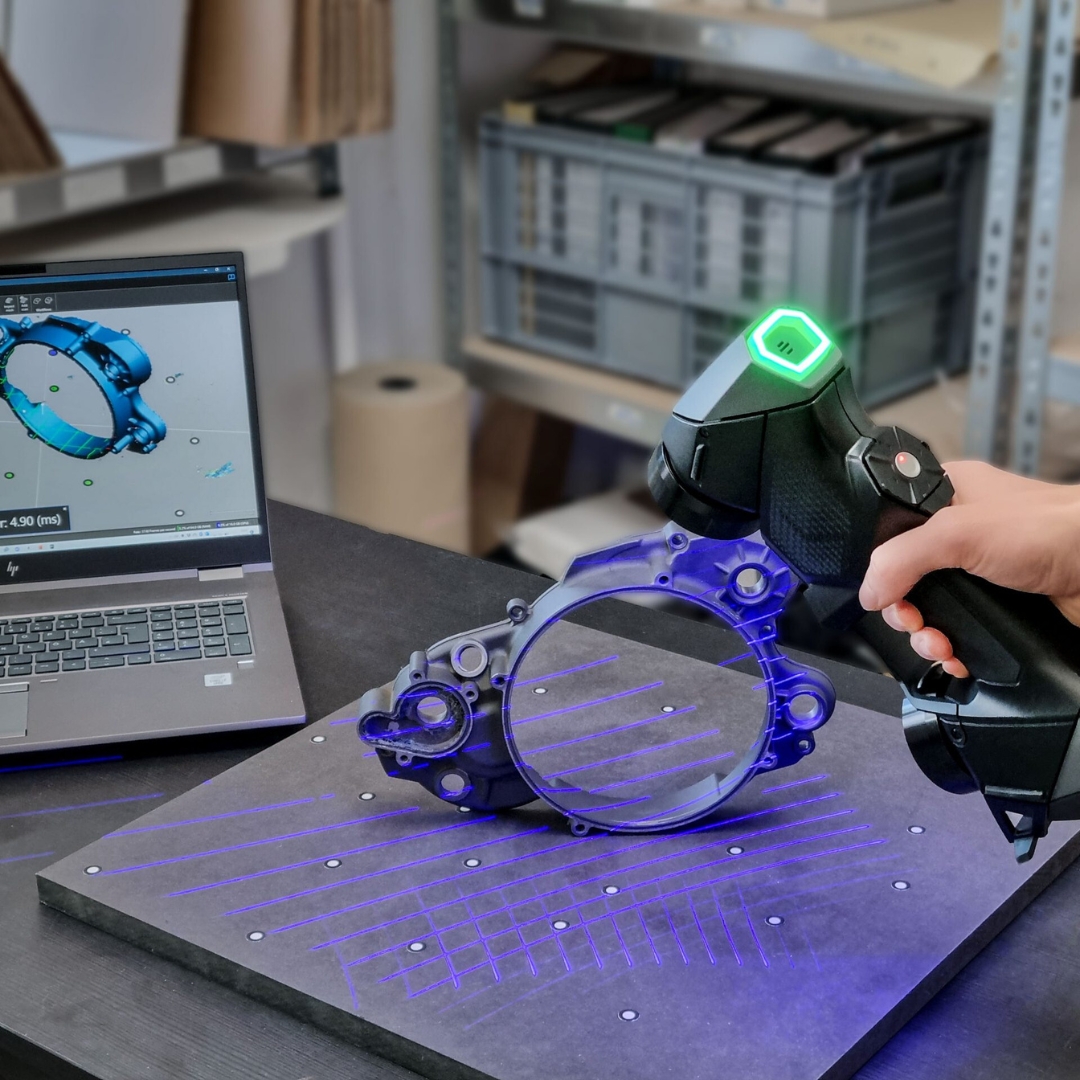

3D scanning is a cutting-edge technology that captures the shape, size, and details of physical objects using lasers or structured light. It is widely used for reverse engineering, quality inspection, CAD (Computer-Aided Design), and 3D printing. Whether the object is large, small, simple, or complex, 3D scanning delivers precise and detailed data. Additionally, this technology can be used on-site or remotely, depending on the client’s requirements.

3D Scanning Malaysia , Reverse engineering 3D scanning , Best 3D Scanning Solutions Provider , Industrial Professional 3D Scanning

Benefits of Using 3D Scanners

Measure Complex Parts

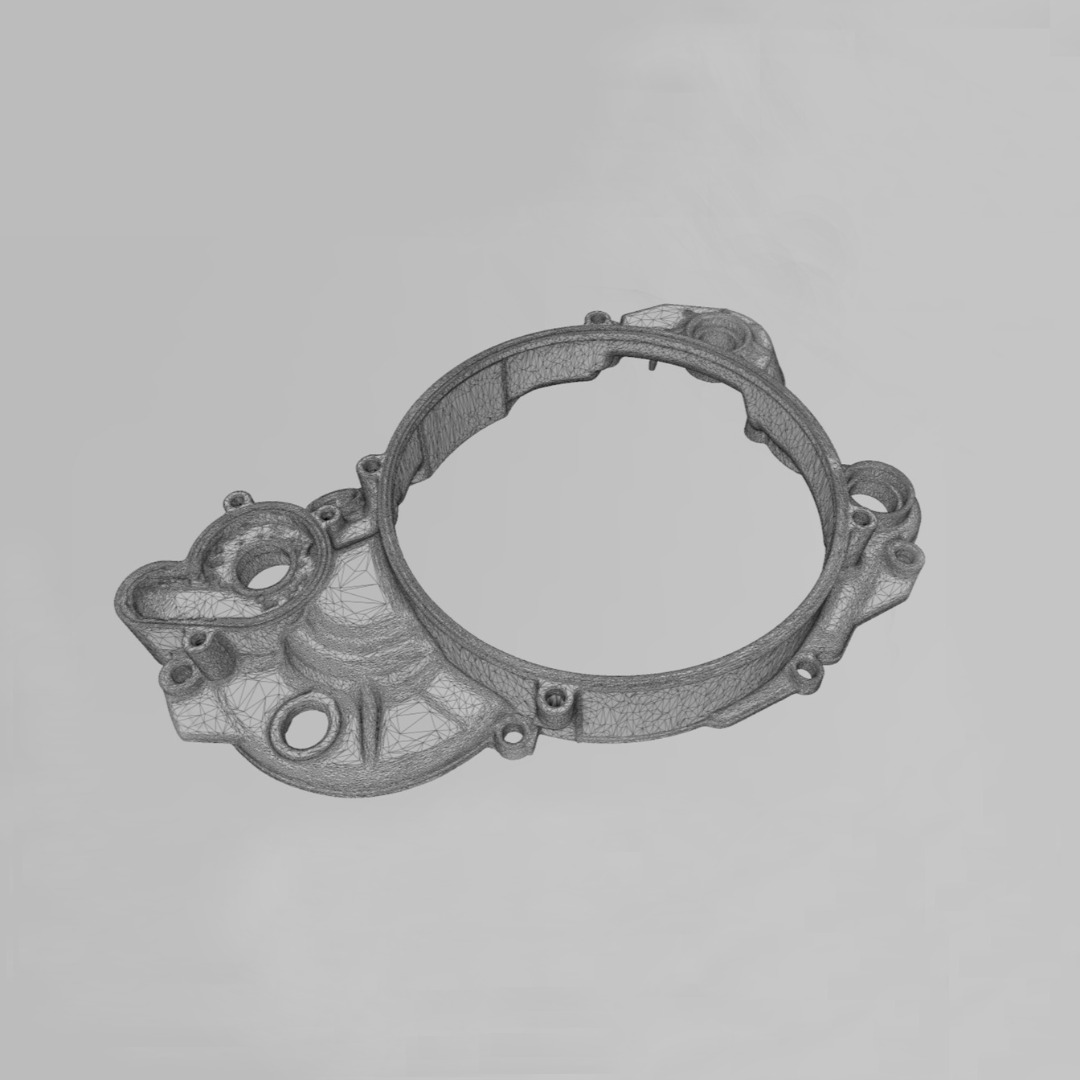

3D scanning is perfect for capturing intricate shapes that are challenging to measure using traditional methods. With laser scanning and non-contact technology, handheld 3D scanners can easily access tight spaces, intricate details, and hard-to-reach areas, such as gears or turbines. This capability allows designers to create highly accurate models and helps engineers develop new products based on existing parts more efficiently.

Enhance Creativity and Innovation

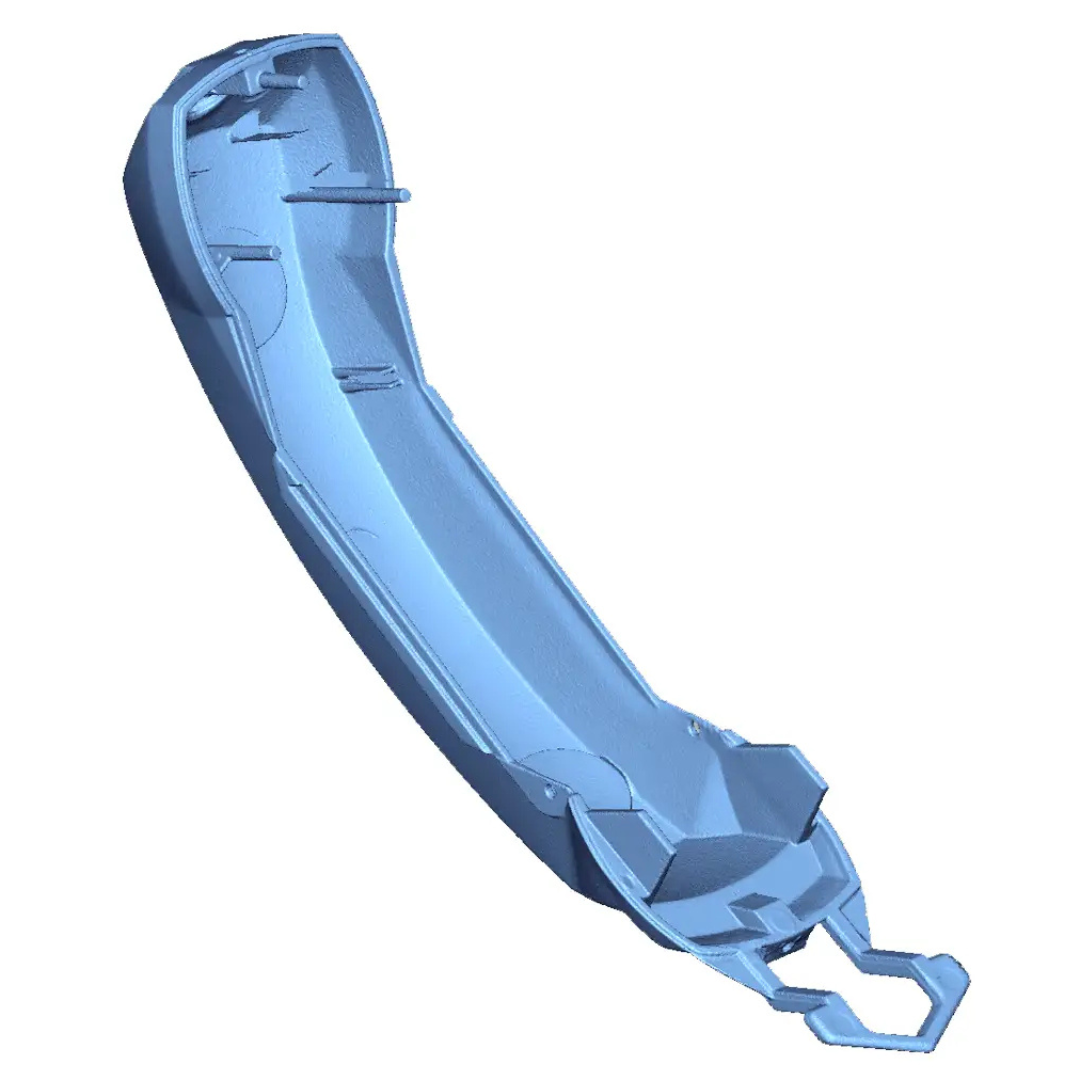

3D scanning plays a vital role in reverse engineering by enhancing creativity and innovation. Designers can use 3D scanners to explore new ideas by working with existing objects. For instance, scanning a car model enables them to modify its curves for better aerodynamics. Additionally, designers can combine scans of multiple objects to create unique, customized designs tailored to specific needs.

Save Time and Money

Using 3D scanning for reverse engineering saves both time and money compared to traditional methods. Instead of relying on manual tools like calipers or coordinate measuring machines (CMMs), which can be slow and complicated, a 3D scanner captures millions of precise data points in seconds. This not only improves accuracy and reduces errors but also speeds up the entire design process.

3D Printing FDM , 3D Printing service Singapore , 3D Printing service KL, 3D Printing SLA, 3D Scanning Malaysia

Selection Of Industries Benefiting From 3D Scanning Services:

Industrial Machinery

- Reverse Engineering

- Mechanical Design & Modification

- Tooling Design & Modification

- Rapid Prototyping

- Modeling and Design

Reverse Engineering Services

If you’re starting a reverse engineering project, it’s a decision you likely didn’t make lightly. It’s crucial to choose a service provider who not only understands your specific needs but also recognizes the challenges that come with such projects. These challenges can often lead to unexpected costs and delays. This is where our expertise stands out. We have successfully handled a wide range of projects, from machine components and plastics to engine block castings and more.

Our Reverse Engineering Project Team is skilled at analyzing your data and providing advice on the most effective course of action to help you reach your goals.

We offer flexible solutions, whether you need a comprehensive, all-in-one approach or assistance with manipulating STL file data. Regardless of whether your files are scanned by us or another 3D scanning service, we are ready to support you.

Unlike others who only provide basic step files, we take it a step further. We reverse engineer your scans into editable CAD formats, such as SolidWorks, making it easy for you to modify and refine your designs.

3D Printing service malaysia , 3D Printing service KL, 3D Scanning Malaysia

Why Choose 3D Scanning?

3D scanning is a game-changer for industries looking to improve efficiency, accuracy, and innovation. Whether you’re working on complex parts, exploring creative designs, or aiming to save time and costs, 3D scanning offers a reliable and effective solution. For the best 3D scanning services in Malaysia, trust a professional provider to meet your reverse engineering needs.

3D Scan

3D Scan

Reverse Engineering

Reverse Engineering

3D Printing service malaysia , 3D Printing service KL, 3D Scanning Malaysia

Collaborate with 3D printing bureau to choose the best material and optimize build orientation for your project’s needs. Explore our 3D Printing Materials Guide to learn about various plastic and metal materials across technologies.

Discover more about additive manufacturing at projet.my. For assistance, reach out to our applications engineer at enquiry@projettech.com or +604-2858 335.