In today’s business landscape, your company, like many others, is exploring the innovative fields of 3D printing and additive manufacturing. Perhaps your team has developed an optimal design, drawn in by the inherent advantages of 3D printing. Yet, despite these clear benefits, managing operational costs and implementation remains a challenge.

However, even with these compelling advantages, navigating operational costs and implementation presents significant hurdles. You may be contemplating investing in a 3D printer but are cautious due to uncertainties about costs and the required technological expertise. This dilemma raises a fundamental question: should we procure our own printer or rely on outsourcing for our 3D printing needs?

These internal deliberations have long been pivotal in manufacturing, especially within the dynamic realm of 3D printing. Fortunately, the industry has evolved to a stage where owning a printer and outsourcing are not necessarily mutually exclusive approaches.

Companies that have their own 3D printing capabilities may find themselves unable to handle large-scale production demands. This is when customers turn to them for outsourcing their production needs.

Reasons to 3D Print through a Service Bureau

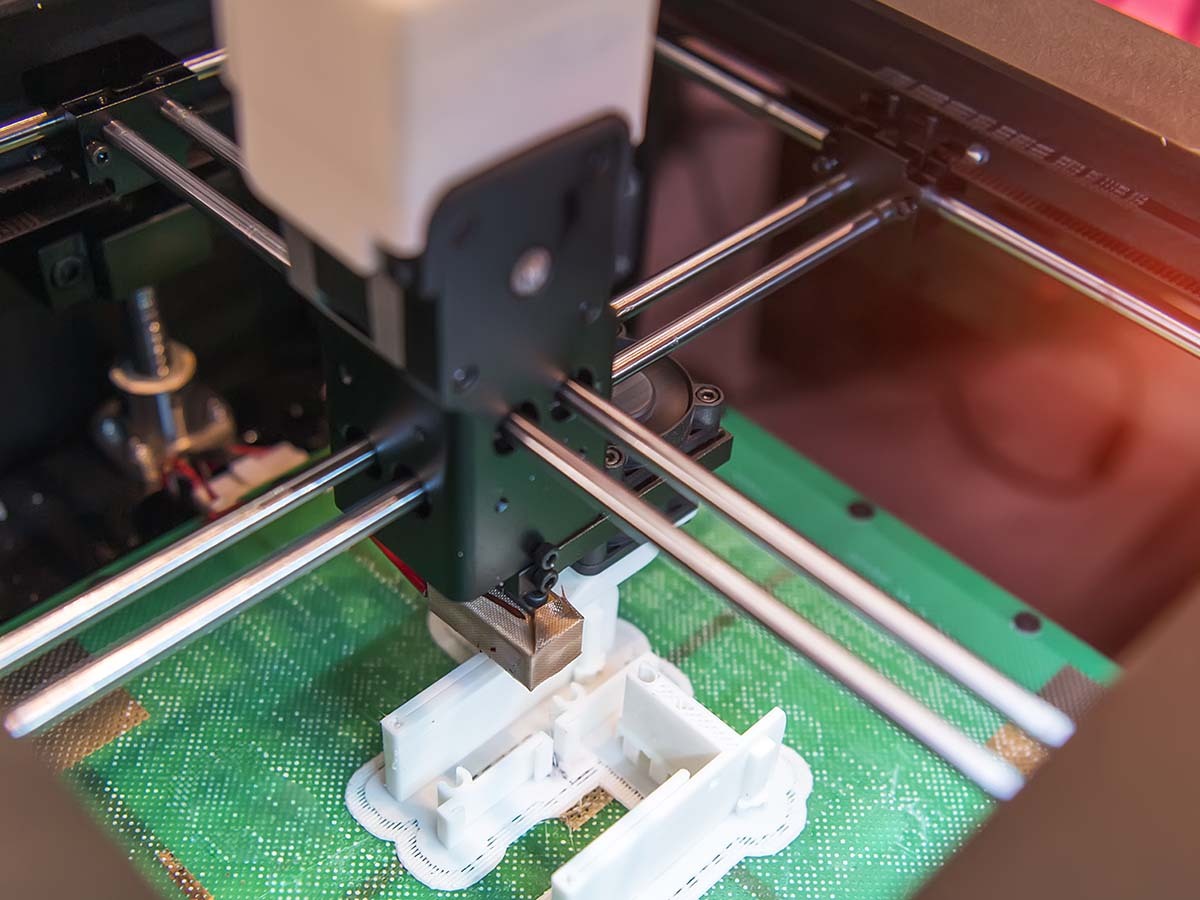

Owning and running a 3D printer can be fulfilling as you oversee the entire process from design to the finished product. However, tasks such as troubleshooting and fine-tuning settings for quality prints can become burdensome and laborious. After investing substantial time and resources, you may discover that your 3D printer has limitations, prompting a desire for more options.

Continue reading to explore the top reasons why opting for a service bureau like Projet for printing your designs could be advantageous.

Expert Advice & Assistance

Our expertise in additive manufacturing excels in managing high-volume, low-variety part designs with unmatched consistency and reliability.

Service providers like Projet are strategically equipped to maximize the benefits of additive manufacturing tailored to your unique requirements. We excel in translating creative ideas into tangible products swiftly and seamlessly, utilizing state-of-the-art technologies and comprehensive services.

Wide range of technologies, materials, and colors

Additive manufacturing is expanding across major industries due to technological advancements and evolving materials, from rigid plastics to high-strength metals. Customers appreciate 3D printing for its flexibility, cost-effectiveness, and speed, though managing complex operations can be daunting.

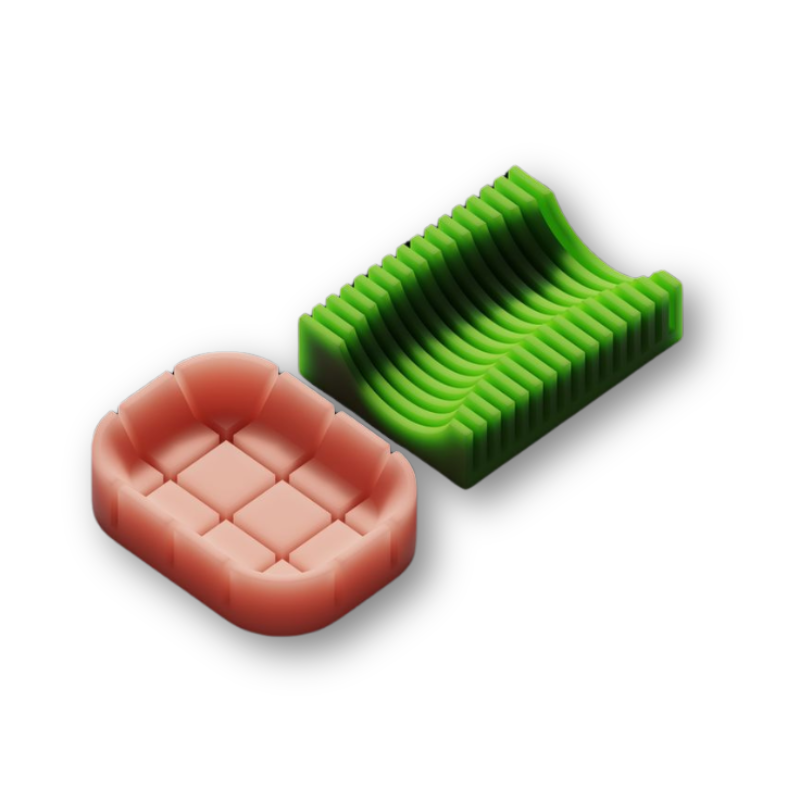

Service bureaus excel by offering advanced technologies like FDM, SLA, SLS, MJF, and SLM, which require precise handling and high temperatures. They provide diverse materials and expertise, unlocking capabilities beyond consumer-grade printers. However, integrating additive metals remains challenging due to costs and technical demands.

Service bureaus like Projet enable large-scale printing in one piece, accommodating everything from intricate small details in high-detail stainless steel to oversized prototypes in robust resin, offering a wider range of options to match initial ideas.

Big Financial Investment

Investing in additive manufacturing technology requires a significant upfront financial commitment. In addition to the initial purchase cost, it involves expenses for software setup, ongoing maintenance, and procurement of materials and consumables. Implementing this technology can disrupt current workflows and necessitate operational adjustments.

Initially engaging a service bureau can facilitate this transition by offering expert guidance in selecting technology that aligns with your business objectives. This strategic approach ensures seamless integration of 3D printing, boosting operational efficiency and fostering innovation.

When considering the expenses of owning a quality 3D printer—such as replacement parts, upgrades, and filament—printing in-house can become costly. In contrast, outsourcing to a service bureau often proves more economical, especially for large-volume projects.

Part Manufacturability

Complex parts often require specialized construction techniques or materials that exceed the capabilities of internal operations, especially in terms of appearance, texture, or functionality.

Service bureaus facilitate exploration of new design methods and materials, fostering innovation and expanding possibilities. This collaboration can seamlessly complement internal operations. Additive manufacturing, particularly effective for producing custom jigs and fixtures, proves invaluable for traditional manufacturers.

Moreover, service bureaus excel in assembling large or intricate parts, ensuring robustness and uncompromising quality.

Connect with Projet:

If you’ve had a positive experience with Projet that you’d like to share, please reach out to us at enquiry@projettech.com. We eagerly anticipate hearing from you.

For additional information, visit our website for comprehensive details about our services and contact information. Our friendly team is ready to assist you at any time.

Get your next project started with Projet by reaching out to our human touch customer service personnel for enquiry or try our instant quote for immediate pricing feedback.