Rapid Prototyping & Fabrication

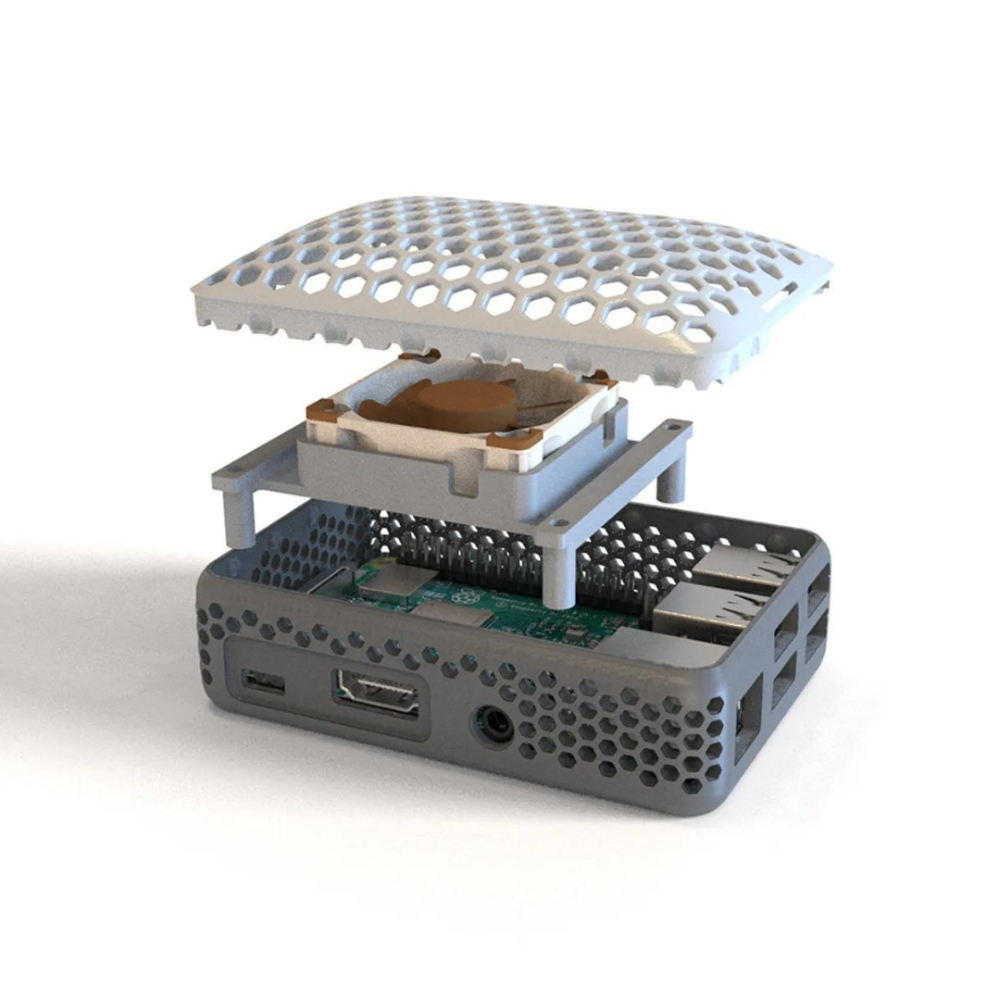

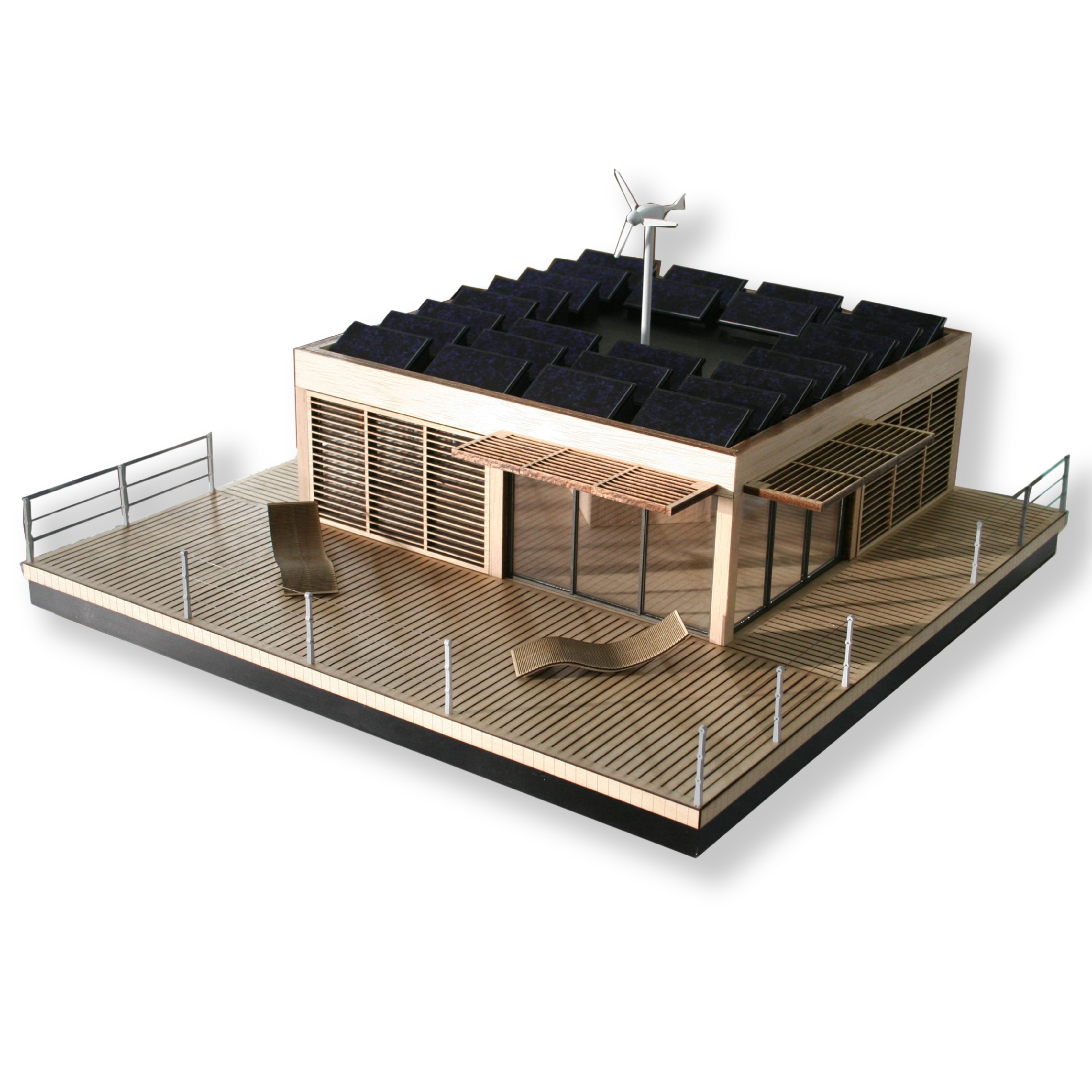

Rapid prototyping or on-demand manufacturing service is not just a preliminary step; it’s an essential pillar of the product development process. Through thorough testing and evaluation, prototypes ensure a product’s viability, guarantee that it meets relevant regulations, and help reveal critical areas for improvements—before product hits the market. It’s not just about designing- it’s about holding your designs in your hands, tweaking them in real-time.

Projet can help assess concept’s ability to meet given requirements and application. We offer broad range of technologies, capable to complete the delivery as fast as in 1 day.

What is Rapid Prototyping?

Rapid prototypes allow design and engineering teams to swiftly turn their ideas into reality, facilitating real-time feedback and concept testing. Our solutions are a game changer for teams aiming to rapidly transition from concept to reality. Leveraging expertise in industrial design, we provide a valuable combination of skill and cutting-edge technology, enabling swift product development. Ideal for those seeking quick and efficient creation, refinement, perfection of their process and product designs, reducing time and cost associate with the entire design process.

Advantages with Projet :

- Swift idea realization : Enables the rapid transformation of concepts into tangible products.

- Flexible and speedy : Enhance the evaluation and refinement process, enabling designers, engineers, and manufacturers to critique multiple revisions in less time, leading to seamless improvements.

- Accelerate design cycles : Traditionally take weeks or months to complete, in a matter of hour with 3D printing, we help to improve the overall efficiency.

- Iterate quickly and often : With digital design iteration, our clients can test and improve their parts as often as necessary without costly investment in tooling & modification, getting to optimal design faster and affordably.

Our Values

We boast an extensive and multidisciplinary engineering expert team to support for quick, short-term tasks or complex, long-term projects. Our wide range of rapid prototyping services is tailored to the unique needs of our clients:

- Consulting services for parts or prototype manufacturing in small production runs

- 1-stop rapid fabrication centre

- Prototype manufacturing and assembly

- Development and manufacturing of test benches

- Surface finishing of prototypes and/or small batch manufacturing

Rapid prototyping to volume production

Projet actively revolutionizing with technology – propelling entire industries forward by showcasing its impact in every stage, from rapid prototypes to crafting end-use parts that redefine efficiency.

This isn’t just a vision – it’s the reality we’re shaping. We’ve pioneered a groundbreaking solution that revolutionizes how parts are designed and prototyped. By leveraging the unique abilities, we’re able to speed up product development, offer cost-effective low-volume manufacturing with no minimum order quantity, and shore up manufacturing workflows.

Volume production

Time is money, and we’re saving you both. Think of us as production time machine. We’ll warp 3D printing volume orders from months to weeks, leaving our clients with more time to focus on what matters most.

- High-quality finish, meets market standards

- Durable and long-lasting materials specifications

- Low mix high volume/ high mix low volume

- Custom end-use parts/ mass customization

Types of Prototype

| Types of prototypes | Description |

|---|---|

| Functional prototype | Used for functional testing such as fit, assembly, ease of use, ergonomics, etc. These types of prototypes often include moving parts that allow the product to function as intended before actual production begins. |

| Cosmetic prototype | Used to evaluate the appearance of the product. They are usually made using simple materials and are not built to withstand wear and tear. |

| Appearance prototype | This is the prototype that is used for showing potential customers how the product will look when it’s done. |

| Mock up prototype | This is simply a drawing of the finished product. |

| Low volume prototype | These are usually built by hand using inexpensive materials or by printing them with 3D printing. |

| Production prototype | This type of prototype is built using the same processes that will be used to manufacture the actual product and is made from the same materials. |

| High volume prototype | This uses the same manufacturing processes that will be used to create the final product but is built from less expensive materials and tooling. |

| Quality assurance prototype | This type is used to test the final design and make sure that it conforms to the specifications and requirements of both the manufacturer and the customer. |

| Fit, form and function prototype | If none of the above types of prototypes address the needs of the designers or engineers, the F2F prototype is created. |

| Pre-production sample | After a prototype is made, a sample is ordered from the factory to verify the designs and ensure that everything works correctly. |

| Manufacturing prototyping | This is a fully assembled sample of the final product that is shipped directly from the factory to the customer for testing and review. |

| Engineering prototype | This is used to evaluate the engineering specifications of the product prior to manufacturing. |

Application

Our competencies

We are a highly dependable mechanical powerhouse with an extensive array of additive manufacturing (3D Printing) & subtractive manufacturing capabilities. Catering from one-off prototyping to low-volume production, we offer solutions that span from basic to industrial, including cosmetic finishing manufacturing.

3D Printing

SLS,SLA,SLM,FDM,MJF,PµSL

- Tolerances accuracy ± 0.02 mm

- Class 1 surface finishing

- Engineering grade material

Laser Cutting

CO2 Laser

- Bending, welding

- Stainless steel, aluminium

- Thermoplastic, tapes & gaskets

- Cutting, boring, engraving, etching

Vacuum Casting

Urethane Casting

- Material flexibility

- High transparency

- Production-like parts

CNC Machining

Milling, Turning

- Tolerances down to ± 0.03 mm

- 3 & 5 axis

- Anodizing, powder coating

- Wide range of material

Start your next project with us today

Manufacturing limitless possibilities with industrial fabrication solutions.