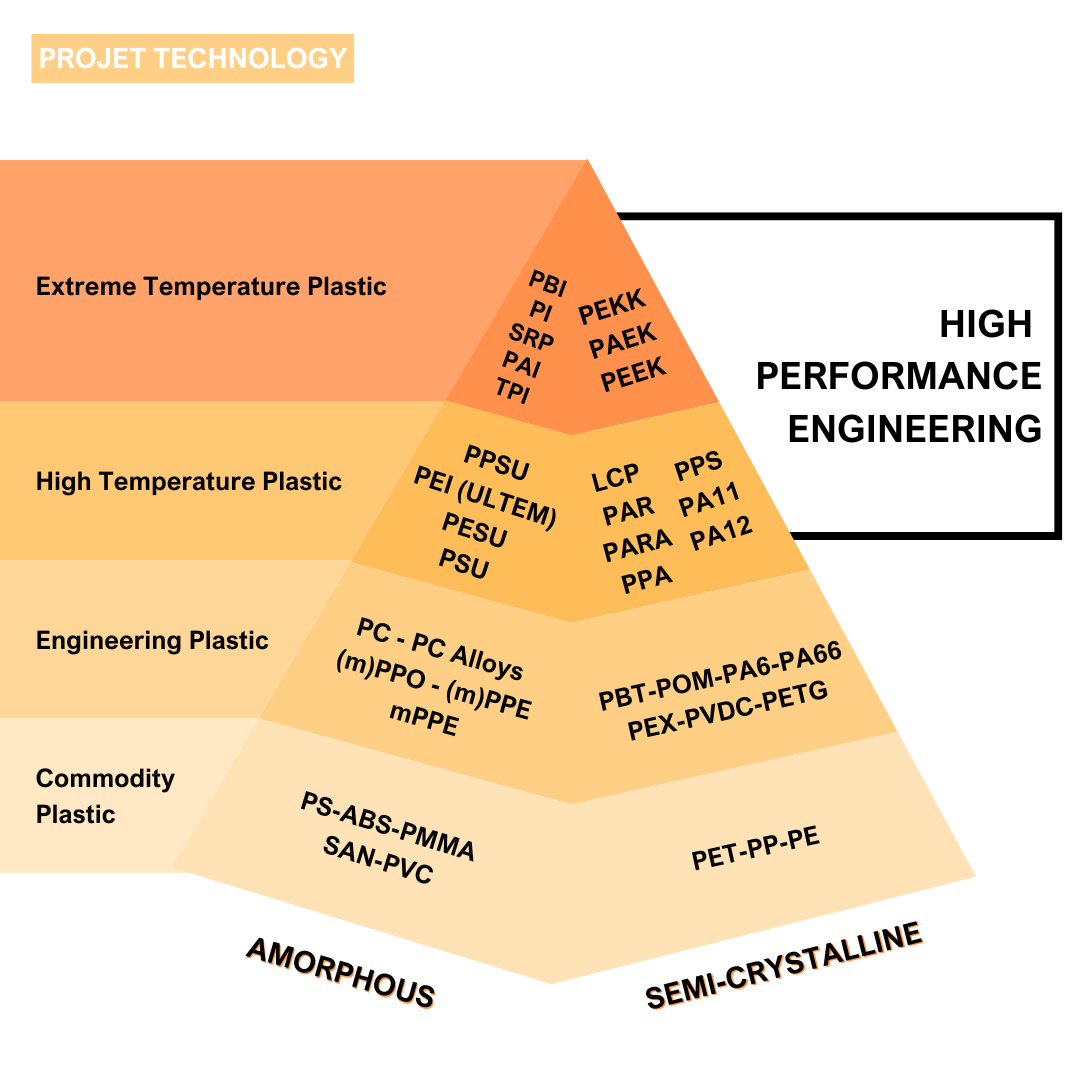

Polymers can be categorized into two main types based on the spatial arrangement of their macromolecules: amorphous and semi-crystalline.

Amorphous materials look translucent and they have lower fatigue and stress resistance but better impact resistance.

Some examples of polymers with an amorphous morphology are:

- polycarbonate (PC)

- polyetherimide (PEI or Ultem®)

- acrylonitrile butadiene styrene (ABS)

- polystyrene (PS)

- polysulfone (PSF)

Semi-crystalline polymers offer greater stiffness and mechanical stability over a wider temperature range.

Among the semi-crystalline polymers there are:

- polyamides (PA)

- polyethylene (PE)

- polyacetal (POM)

- polyethylene terephthalate (PET).

Both types, when reinforced, show significant improvements in strength and stiffness, especially beyond their glass transition temperature (Tg).

What is the difference between PEEK and PEKK?

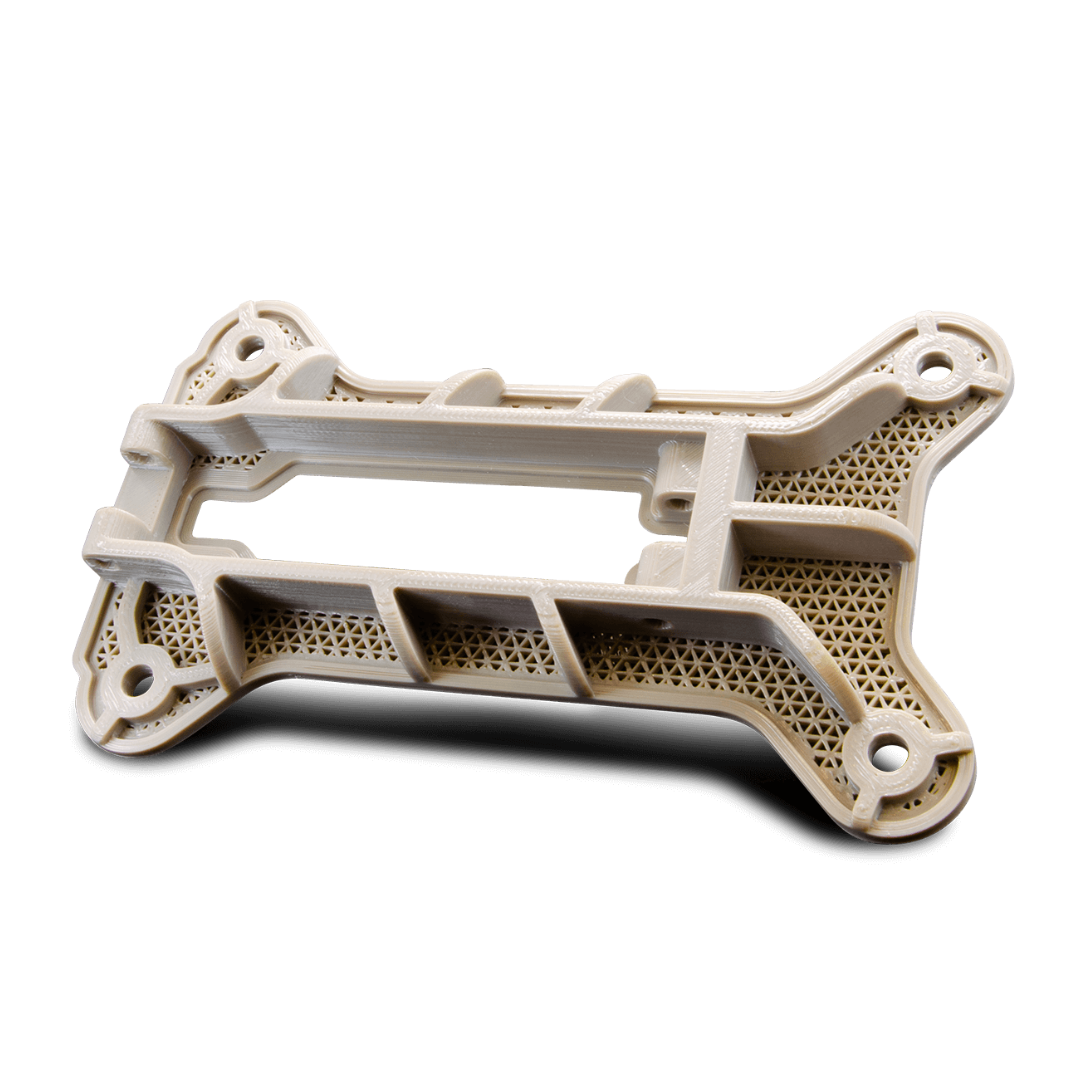

Both PEEK and PEKK, popular members of the semi-crystalline PAEK (polyaryletherketones) family, are known for their exceptional mechanical, thermal, and chemical resistance. Their degree of crystallinity varies significantly based on the processing method, and they have demonstrated compatibility with 3D printing technologies like Fused Filament Fabrication (FFF) and Fused Deposition Modeling(FDM).

Polyetherketoneketone (PEKK)

Polyetherketoneketone (PEKK) is a high-performance thermoplastic known for its superior chemical and mechanical resistance, thanks to its unique molecular structure with two ketone groups per repeating unit. This composition differentiates PEKK from other plastics and allows its properties to be customized by adjusting component ratios. PEKK is ideal for industries like aerospace, automotive, and medical, where materials must endure extreme temperatures, harsh chemicals, and mechanical stress, making it highly versatile for demanding applications.

Polyetheretherketone (PEEK)

Polyether Ether Ketone (PEEK), a high-performance polymer with a unique molecular structure alternating between ether and ketone groups, offers exceptional mechanical strength, thermal stability, and chemical resistance, making it a highly sought-after material across various industries.

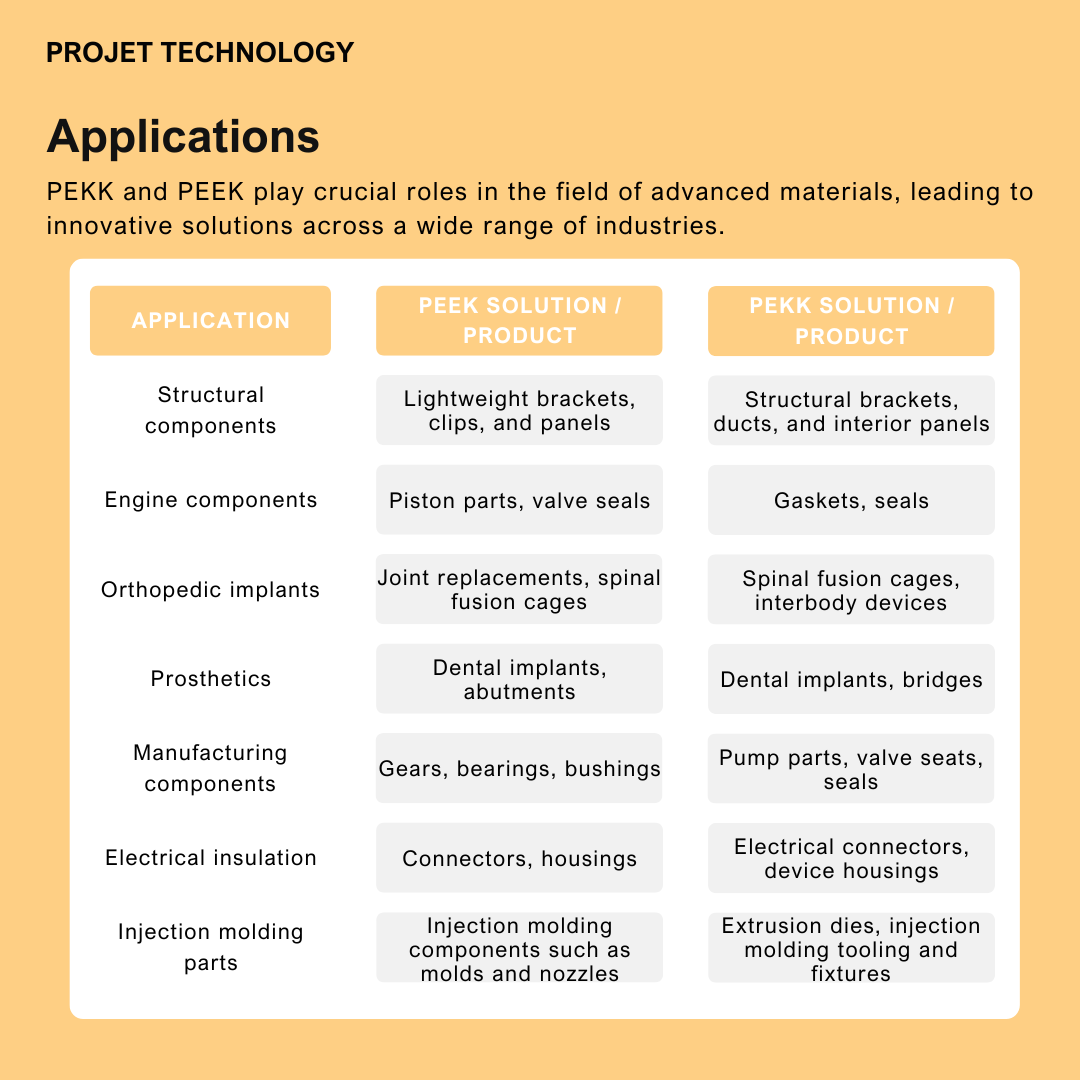

Type of Application of PµSL 3D Printed Parts

Connect with Projet:

If you’ve had a positive experience with Projet, we would love to hear from you! Your feedback helps us improve and better serve our community. Please share your feedback by contacting us at enquiry@projettech.com. We look forward to hearing from you.

For additional information, visit our website for comprehensive details about our services and contact information. Our friendly team is ready to assist you at any time.