Choosing the right post-processing finish is crucial. While both Pad Printing and UV DTF Printing deliver durable, high-quality graphics, they excel in different areas.

Which is the Best for your parts?

You’ve designed the perfect part. It functions flawlessly, and the material is just right. Now for the final, crucial touch: the graphics. Whether it’s a logo, instructional text, or a decorative design, the printing method you choose will define the product’s final look and durability.

Two popular and powerful post-processing options are Pad Printing and UV DTF (Direct-to-Film) Printing. While both deliver high-quality, durable graphics, they operate very differently and excel in completely different scenarios. Making the wrong choice can lead to higher costs, slower production, or a finish that doesn’t meet your expectations.

This guide will break down everything you need to know about pad printing versus UV DTF printing, from how they work to their unique pros and cons. By the end, you’ll be able to confidently select the right method for your project.

What is Pad Printing?

Pad printing is a time-tested and versatile printing process that has been an industry standard for decades. It works by transferring a 2D image onto a 3D object. Think of it as a highly sophisticated stamping process.

The core of this method is a flexible silicone pad that picks up ink from an etched plate (called a cliché) and presses it onto the part’s surface. This flexibility allows pad printing to conform to curved and irregular surfaces with remarkable precision.

How Does Pad Printing Work?

The process is straightforward but requires precision setup:

The Cliché: First, an image is etched into a metal or plastic plate, creating a “cliché.” This plate is then flooded with ink, and a doctor blade scrapes the surface clean, leaving ink only in the etched areas.

The Ink Transfer: A soft silicone pad presses down onto the cliché, picking up the ink from the etched image.

The Print: The pad then moves over to the part and presses down, transferring the ink image onto the object with a clean, crisp finish.

Advantages of Pad Printing

Crisp, Solid Graphics: Pad printing is the champion for creating smooth, opaque, and incredibly sharp solid-color graphics.

Precise Color Matching: It excels at hitting exact Pantone colors, which is critical for maintaining brand consistency.

Excellent on Curved Surfaces: The soft silicone pad can easily wrap around curves and print on uneven or recessed areas where other methods might fail.

Proven Durability: As a long-established process, its durability is well-understood and reliable, with specialty inks available for unique requirements like food-contact safety.

Limitations of Pad Printing

No Gradients or Photos: It is a single-color-at-a-time process and cannot reproduce photographic images or smooth color gradients.

Slower Setup: Creating custom clichés and fixtures for each new job makes the initial setup and changeovers more time-consuming.

Best for High Volumes: Due to the setup time, pad printing is most cost-effective for larger production runs where the cost can be spread across many units.

Material Constraints: Adhesion can be challenging on certain materials, sometimes limiting your substrate options.

What is UV DTF Printing?

UV DTF (Direct-to-Film) Printing is a revolutionary transfer technology that combines the versatility of UV printing with the ease of a decal. Instead of printing directly onto the part, this method prints a design onto a special film, which is then transferred to the final product.

This process creates a durable, vibrant, and slightly raised “sticker” or “transfer” that can be applied to a vast range of materials without heat presses or complex equipment.

How Does UV DTF Printing Work?

It’s a multi-step process that separates the printing from the application:

Printing on ‘A’ Film: A specialized UV printer prints the design in reverse onto a sheet of adhesive-coated “A” film. This usually includes a layer of color ink, a layer of white ink, and a final layer of varnish for durability.

Laminating with ‘B’ Film: The printed “A” film is then fed through a laminator, which applies a “B” film (a transparent carrier sheet) over the top.

Creating the Transfer: The two films are pressed together, and the “B” film adheres to the printed design. The design can then be cut out from the sheet.

Application: To apply, you simply peel the backing off the “A” film, position the transfer on your product, and press down firmly.

Final Peel: Finally, you peel away the transparent “B” film carrier, leaving only the vibrant, durable UV-cured design on the surface.

Advantages of UV DTF Printing

Incredible Material Versatility: Since it’s a transfer, it can be applied to almost any hard, non-porous surface: metal, plastic, glass, ceramic, wood, and more.

Full-Color, Complex Graphics: UV DTF excels at producing photorealistic images, intricate logos with fine details, and smooth gradients.

No Heat Required: The application is a simple pressure-based transfer, making it safe for heat-sensitive materials.

Excellent Durability: The resulting transfer is highly resistant to scratches, water, and UV fading, making it suitable for many indoor and outdoor applications.

On-Demand Application: Transfers can be printed in batches and stored, allowing for on-demand application as needed, perfect for product personalization.

Limitations of UV DTF Printing

Manual Application: The final transfer is applied by hand, which can introduce misalignment or bubbles and is less suited for high-speed, automated production lines.

Tactile Feel: The design sits on top of the surface and has a noticeable, slightly raised edge and feel, unlike pad printing where the ink feels more integrated.

Not for Porous or Very Flexible Surfaces: It works best on hard, smooth surfaces. It is not suitable for fabrics or extremely flexible, rubbery materials.

Multi-Step Process: The workflow involves printing, laminating, and manual application, which can be more labor-intensive per piece than an automated direct-print method.

Comparison: Pad Printing vs. UV DTF

| Factor | Pad Printing | UV DTF Printing |

|---|---|---|

| Image Complexity | Best for solid, single-color graphics. | Excellent for full-color photos, gradients, and fine details. |

| Color Matching | Excellent. Precise Pantone matching is a key strength. | Good. CMYK-based process, making exact Pantone matching harder. |

| Setup Speed | Slower. Requires custom clichés and fixtures for each job. | Fast. Prints digital files directly to film; no custom tooling. |

| Application Speed | Fast and automated for high volumes. | Slower, manual application per piece. |

| Best Production Volume | High volume runs. | Low to medium volume, prototypes, and personalization. |

| Surface Feel | Perfectly smooth, feels integrated with the part. | Slightly raised with a tangible edge. |

| Surface Geometry | Excellent on irregular and curved surfaces. | Best on flat or gently curved surfaces; can wrap with care. |

| Upfront Cost | Higher, due to tooling (clichés, fixtures). | Lower, as no physical tooling is needed. |

Which Process Should You Choose?

Choose Pad Printing When:

You are producing a large batch of identical parts and need high-speed, automated application.

You need exact Pantone color matching for strict brand guidelines.

The graphic is a simple, solid-color logo or text.

The part has a very complex curve or recessed area that requires a highly conforming printing process.

A perfectly smooth, integrated feel is non-negotiable.

Choose UV DTF Printing When:

You need to print on a wide variety of materials and shapes with one process.

Your artwork involves photographs, gradients, or complex multi-color designs.

You are producing a small quantity, prototypes, or offering product personalization.

Minimal setup cost and fast turnaround for the print itself are top priorities.

You can accommodate a manual application process in your workflow.

3D Printing Service Malaysia , 3D Printing service Singapore , 3D Printing service KL , 3D Printing service Selangor, 3D Scanning Malaysia

Why Partner with Projet ?

Selecting the right manufacturing technology is important—but choosing the right manufacturing partner is what truly drives success. Companies across the electronics, automotive, consumer products, aerospace, and medical industries trust Projet because we are more than just a supplier; we are a dedicated partner in their success.

Here’s what sets us apart:

A True One-Stop Solution

We provide a seamless experience by offering a comprehensive suite of manufacturing services under one roof. This integrated approach streamlines your supply chain and simplifies the journey from concept to a market-ready product.

Engineering Expertise You Can Count On

Our experienced engineering team acts as a dedicated extension of your own. We excel at solving complex manufacturing challenges and collaborate closely with you to optimize your designs for quality, cost-effectiveness, and manufacturability.

Flexible Production Volumes to Match Your Needs

Whether you require a single prototype or a high-volume production run, our manufacturing capabilities are designed to scale with your demands. We support your product’s entire lifecycle, from initial launch to full-scale production.

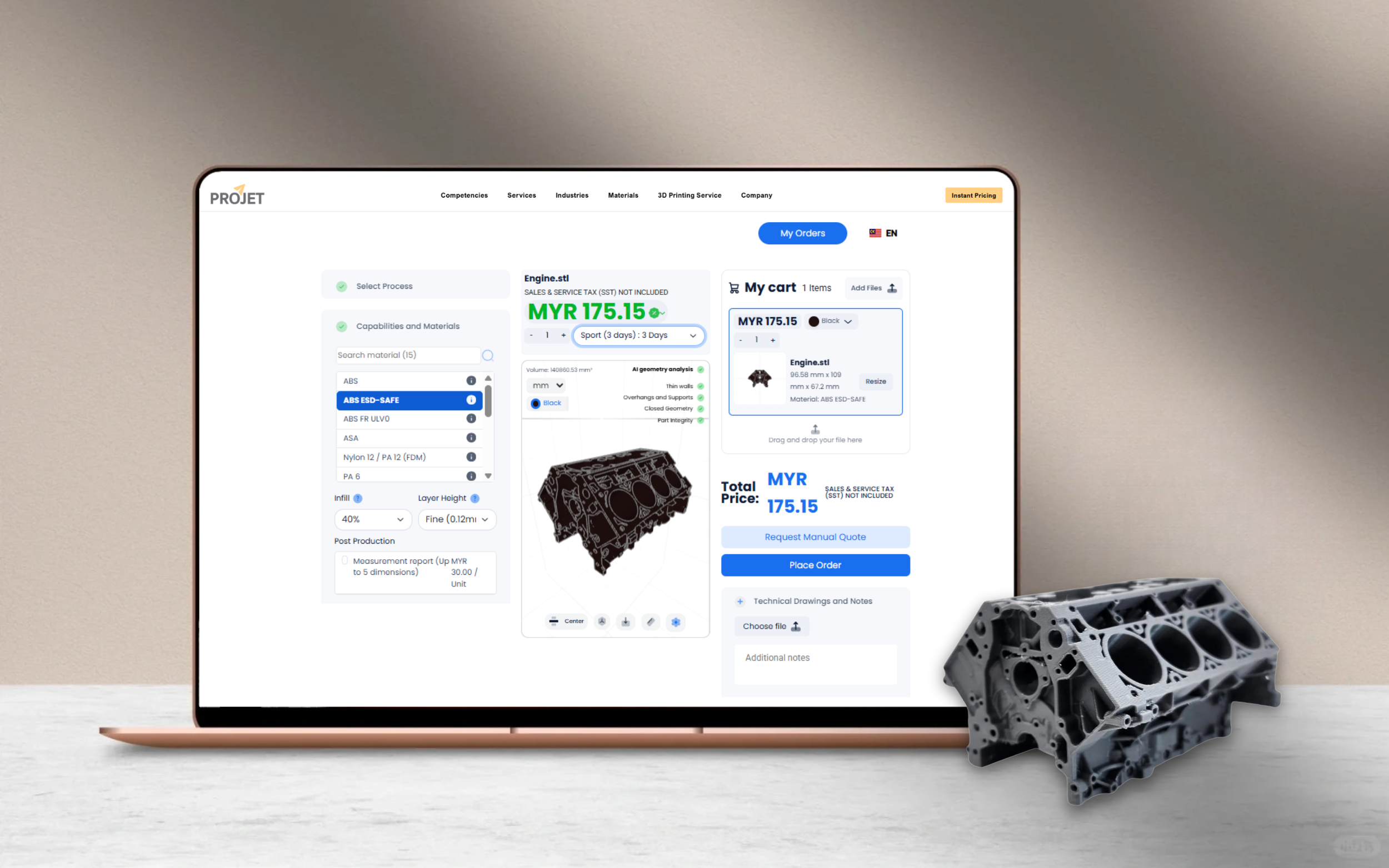

Rapid Turnaround for a Faster Time-to-Market

In today’s fast-paced market, speed is a crucial advantage. We deliver fast, transparent quotes and pride ourselves on our rapid turnaround times, helping you get your innovative products to market sooner.

3D Printing Services

Instant Price