Multi Jet Fusion

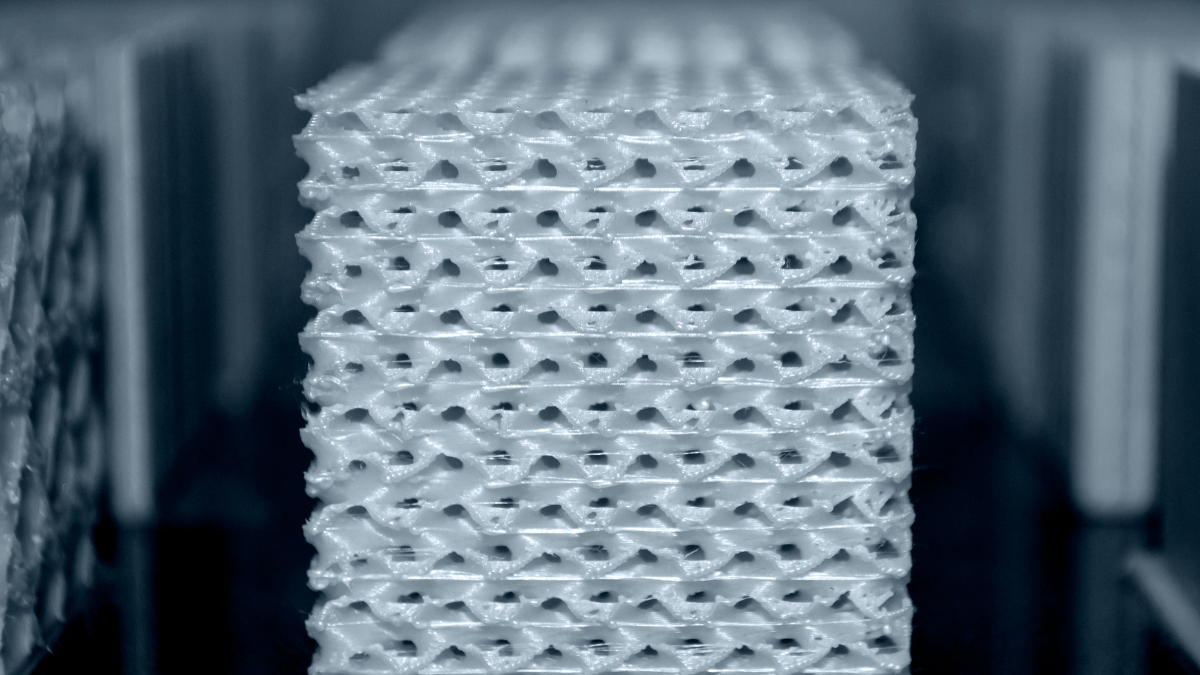

Looking for fast production of complex parts with precise features and consistent mechanical properties? Multi Jet Fusion (MJF) 3D printing is the perfect solution. It’s ideal for creating functional prototypes, bridge production, and low-to-medium volume parts.

Manufacturing with MJF 3D printing

MJF 3D printing is suitable for :

- Functional prototypes

- Low-volume production of end-use components

- Production aids like jig & fixture

| Industrial | |

|---|---|

| Maximum build size | W284 X L380 X H380mm |

| Best lead time | 3 days |

| Dimensional accuracy | with a lower limit of ± 0.3 mm |

| Layer height | 80-90 μm (material dependent) |

| Minimum feature size | 0.5 mm |

Our capabilities

We categorized it into two distinct classes: prototyping and industrial. Each class has specific capabilities that cater to different needs.

Industrial MJF:

- Ideal for quick prototyping

- Suitable for testing designs and concepts

- Geared towards producing end-use parts

- Provides high strength, durability and mechanical properties

- Efficient scalability for small batch and mid-sized series production.

Available MJF materials

3D High Reusability PA 11

3D High Reusability PA 12

3D High Reusability PA 12 Glass Beads

3D High Reusability PP

3D High Reusability TPA

Ultrasint TPU01

3D TPU M95A

3D TPU M88A

Comparison of 3D Printing Processes

| 3D Printing Technology | FDM | SLA | SLS |

| Resolution | ★★★☆☆ | ★★★★★ | ★★★★☆ |

| Accuracy | ★★★★☆ | ★★★★★ | ★★★★★ |

| Surface Finish | ★★★★☆ | ★★★★★ | ★★★★☆ |

| Complex Designs | ★★★☆☆ | ★★★★☆ | ★★★★★ |

| Ease of Use | ★★★★★ | ★★★★☆ | ★★★★☆ |

| Various Materials | ★★★★★ | ★★★☆☆ | ★☆☆☆☆ |

| Applications |

|

|

|

Roller guide

| Material | HP 3D High Reusability PA 11 |

| Industry | Industrial Machinery |

Bellows gimbal

| Material | BASF Ultrasint TPU01 |

| Industry | Automotive , EV |

Cover

| Material | HP 3D High Reusability PA 12 |

| Industry | Automation |

Enclosure

| Material | HP 3D High Reusability PA 12 Glass Beads |

| Industry | Automotive , EV |

Medical brace

| Material | HP 3D High Reusability PA 12 |

| Industry | Medical |

Skeleton hand

| Material | HP 3D High Reusability PA 12 |

| Industry | Medical |

Snap-fit enclosure

| Material | HP 3D High Reusability PA 11 |

| Industry | Consumer Electronics , E&E |

Our competencies

We are a highly dependable mechanical powerhouse with an extensive array of additive manufacturing (3D Printing) & subtractive manufacturing capabilities. Catering from one-off prototyping to low-volume production, we offer solutions that span from basic to industrial, including cosmetic finishing manufacturing.

3D Printing

SLS,SLA,SLM,FDM,MJF,PµSL

- Tolerances accuracy ± 0.02 mm

- Class 1 surface finishing

- Engineering grade material

Laser Cutting

CO2 Laser

- Bending, welding

- Stainless steel, aluminium

- Thermoplastic, tapes & gaskets

- Cutting, boring, engraving, etching

Vacuum Casting

Urethane Casting

- Material flexibility

- High transparency

- Production-like parts

CNC Machining

Milling, Turning

- Tolerances down to ± 0.03 mm

- 3 & 5 axis

- Anodizing, powder coating

- Wide range of material

Start your next project with us today

Manufacturing limitless possibilities with industrial fabrication solutions.

Fused Deposition Modeling (FDM) Capabilities

FDM 3D printing is categorized into two distinct classes: prototyping and industrial. Each class has specific capabilities that cater to different needs.

| Prototyping FDM | Industrial FDM | |

|---|---|---|

| Maximum build size | 250 x 250 x 250 mm | 500 x 500 x 500 mm |

| Standard lead time | From 1 business day | From 3 business days |

| Dimensional accuracy | with a lower limit of ± 0.3 mm | with a lower limit of ± 0.3 mm |

| Layer height | 100-300 μm | 100-300 μm |

| Infill | 15-80% | Solid Infill, Light Infill, Ultralight Infill |

Materials available for FDM 3D printing

Prototyping FDM materials

Ideal for fast and affordable rapid prototyping and modeling.

Prototyping PLA

Prototyping PETG

Prototyping ASA

Prototyping ABS

Prototyping TPU

Industrial FDM materials

Ideal for higher-volume production and bigger parts with better mechanical properties.

Nylon: Markforged Onyx

PEI: ULTEM 9085, ULTEM 1010

ASA: Stratasys ASA

ABS: ABS M30, ABSplus