Metal Fused Filament Fabrication

We provide metal solutions MFFF that are accessible, affordable, and user-friendly. Our adaptable technology has been leveraged by a wide range of industries, including automotive and aerospace, to produce a diverse array of functional parts.

Manufacturing with MFFF 3D printing

Metal Fused Filament Fabrication (metal FFF) — is a manufacturing technique rooted in Metal Injection Molding (MIM). This process involves three key steps: printing, debinding, and sintering. To achieve dense metal components, the metal FFF process includes crucial post-processing stages, particularly debinding and sintering, which convert green parts into fully-formed metal products.

Primarily, Metal FFF 3D printing is used for :

- Custom tools

- Low-volume and specialty parts

- Functional metal prototypes

- Maintenance tools/fixtures - brazing fixtures

- Spare and obsolete parts

- Replacement parts

| Industrial | |

|---|---|

| Maximum build size | W300 X L200 X H180mm |

| Best lead time | 5 days |

| Dimensional accuracy | with a lower limit of ± 0.2 mm |

| Layer height | 80-170 μm (post-sinter) |

| Minimum feature size | 0.2 mm |

Our capabilities

Industrial Metal:

- Ability to customise and create unique, individual products

- Capability of producing complex parts in one process

- Complex geometries with high precision and accuracy

Wide range of manufacturing capabilities, including metal 3D printing for all of your prototyping and production needs.

Available MFFF Materials

- Stainless steel

- Tool steels

- Titanium

- Copper

Comparison of 3D Printing Processes

| 3D Printing Technology | FDM | SLA | SLS |

| Resolution | ★★★☆☆ | ★★★★★ | ★★★★☆ |

| Accuracy | ★★★★☆ | ★★★★★ | ★★★★★ |

| Surface Finish | ★★★★☆ | ★★★★★ | ★★★★☆ |

| Complex Designs | ★★★☆☆ | ★★★★☆ | ★★★★★ |

| Ease of Use | ★★★★★ | ★★★★☆ | ★★★★☆ |

| Various Materials | ★★★★★ | ★★★☆☆ | ★☆☆☆☆ |

| Applications |

|

|

|

Bracket

| Material | Stainless Steel |

| Industry | Automation |

Insert

| Material | Tool steel |

| Industry | Automation |

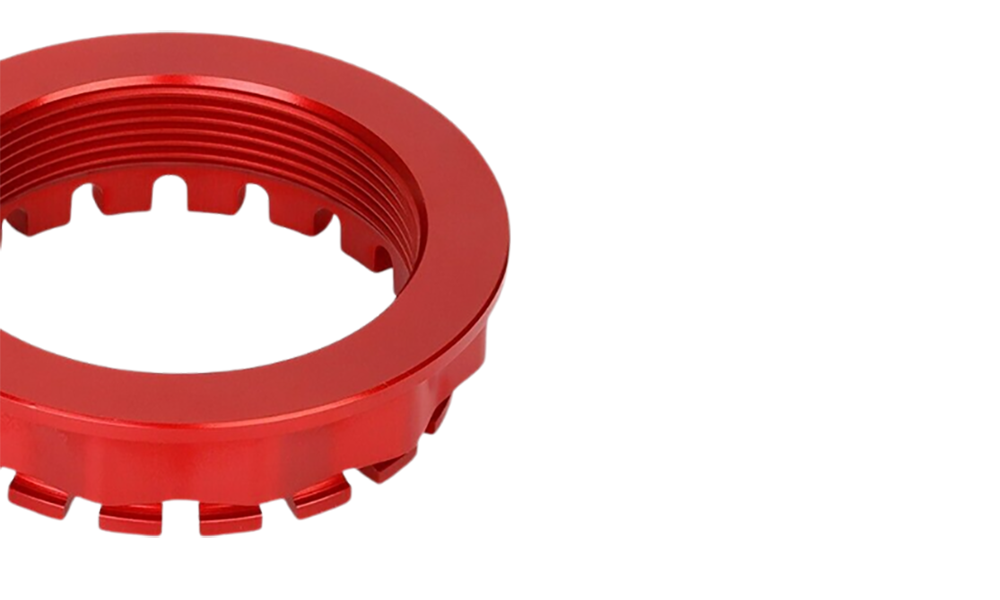

Connector

| Material | Aluminium |

| Industry | FMCG |

Bracket

| Material | Titanium |

| Industry | IOT |

Insert

| Material | Aluminium |

| Industry | Automotive |

Valves

| Material | Tool steel |

| Industry | Aerospace |

Our competencies

We are a highly dependable mechanical powerhouse with an extensive array of additive manufacturing (3D Printing) & subtractive manufacturing capabilities. Catering from one-off prototyping to low-volume production, we offer solutions that span from basic to industrial, including cosmetic finishing manufacturing.

3D Printing

SLS,SLA,SLM,FDM,MJF,PµSL

- Tolerances accuracy ± 0.02 mm

- Tolerances accuracy ± 0.20 mm

- Class 1 surface finishing

- Engineering grade material

Laser Cutting

CO2 Laser

- Bending, welding

- Stainless steel, aluminium

- Thermoplastic, tapes & gaskets

- Cutting, boring, engraving, etching

Vacuum Casting

Urethane Casting

- Material flexibility

- High transparency

- Production-like parts

CNC Machining

Milling, Turning

- Tolerances down to ± 0.03 mm

- 3 & 5 axis

- Anodizing, powder coating

- Wide range of material

Start your next project with us today

Manufacturing limitless possibilities with industrial fabrication solutions.

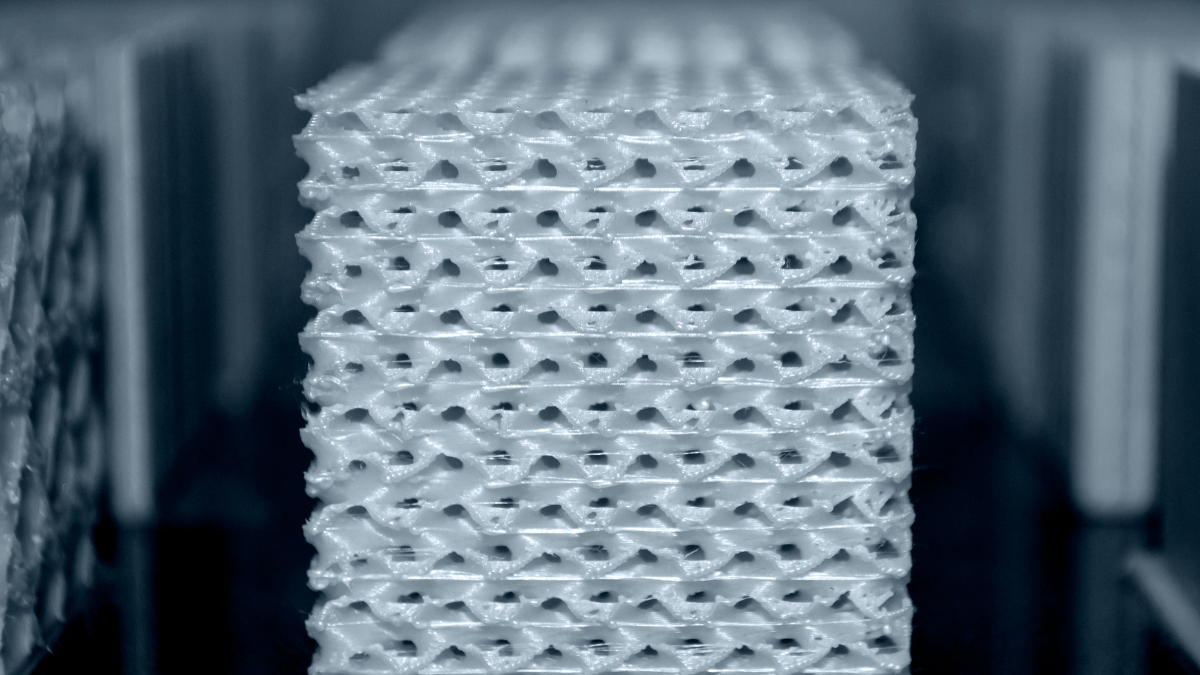

Fused Deposition Modeling (FDM) Capabilities

FDM 3D printing is categorized into two distinct classes: prototyping and industrial. Each class has specific capabilities that cater to different needs.

| Prototyping FDM | Industrial FDM | |

|---|---|---|

| Maximum build size | 250 x 250 x 250 mm | 500 x 500 x 500 mm |

| Standard lead time | From 1 business day | From 3 business days |

| Dimensional accuracy | with a lower limit of ± 0.3 mm | with a lower limit of ± 0.3 mm |

| Layer height | 100-300 μm | 100-300 μm |

| Infill | 15-80% | Solid Infill, Light Infill, Ultralight Infill |

Materials available for FDM 3D printing

Prototyping FDM materials

Ideal for fast and affordable rapid prototyping and modeling.

Prototyping PLA

Prototyping PETG

Prototyping ASA

Prototyping ABS

Prototyping TPU

Industrial FDM materials

Ideal for higher-volume production and bigger parts with better mechanical properties.

Nylon: Markforged Onyx

PEI: ULTEM 9085, ULTEM 1010

ASA: Stratasys ASA

ABS: ABS M30, ABSplus