Having “high resolution” listed in a 3D printer’s specifications doesn’t necessarily guarantee that your printed parts will be accurate or precise.

Understanding the meaning of accuracy, precision, and tolerance is imperative for achieving meaningful 3D print performance for any application. In this post, we’ll parse through what these terms mean and how to think about them in the context of 3D printing.

Tolerance

In 3D printing, tolerance defines precision. A simple explanation for this is your 3D printer has tolerances. Your materials have tolerances. Your projects have tolerances. These define output and ultimately precision. You can remember tolerance as the limitations imposed by your 3D printing technology , your materials and by you.

Tolerance defines the level of precision needed for a project. It refers to the allowable variance in a measurement, based on your application’s needs. In mechanical assemblies, the required tolerances are much stricter than those for simple plastic cases. Achieving high accuracy is essential to ensure that every part fits together perfectly and functions as designed. Think of it as consistently hitting the bullseye in target practice—precision counts!

3D Printing FDM , 3D Printing service Singapore , 3D Printing service KL, 3D Printing SLA, 3D Scanning Malaysia

What are 3D printing tolerances?

In 3D printing, tolerances refer to the permissible variations in specific dimensions and qualities to ensure print accuracy and stability. These include:

- Layer Thickness: The height of each printed layer, typically measured in micrometers (µm). For comparison, a human hair is about 20-100 µm thick.

- Wall Thickness: The minimum thickness needed for walls in your 3D model, usually given in millimeters, to ensure successful printing.

- Detail: Refers to the height or depth of fine features, indicated in millimeters.

- Clearance: The spacing between parts, measured in millimeters, allowing smooth movement.

- Size: Maximum model dimensions, constrained by the 3D printer’s build volume, noted in millimeters or inches.

- Shrinkage: Reduction in model size due to heating or thin walls, noted as a percentage.

- Accuracy: Reflects print precision as a percentage difference between your 3D model and the printed result.

Accuracy

In 3D printing, “accuracy” refers to how closely the printed model matches its original digital design. Imagine aiming for a bullseye: the closer the 3D print aligns with the exact dimensions of your design, the more accurate it is. When using CAD (Computer-Aided Design) software, you create a model with precise measurements. Accuracy describes how well the printed object mirrors this digital model. A good print matches the design accurately, ensuring it reflects the original blueprint faithfully.

Precision

3D Printing service malaysia , 3D Printing service KL, 3D Scanning Malaysia

3D Printing Technology

Various technological processes of 3D printing have varied tolerances that are specific to the process. These tolerances depend on factors like the technology’s mechanism, the movement of its parts, the materials involved, and the design of the item being printed.

- Stereolithography (SLA) & Digital Light Processing (DLP): (min ±0.2 mm)

These resin-based methods use precise light sources to solidify liquid resin, achieving fine details and consistent quality. Supports may be needed for complex shapes to ensure dimensional accuracy.

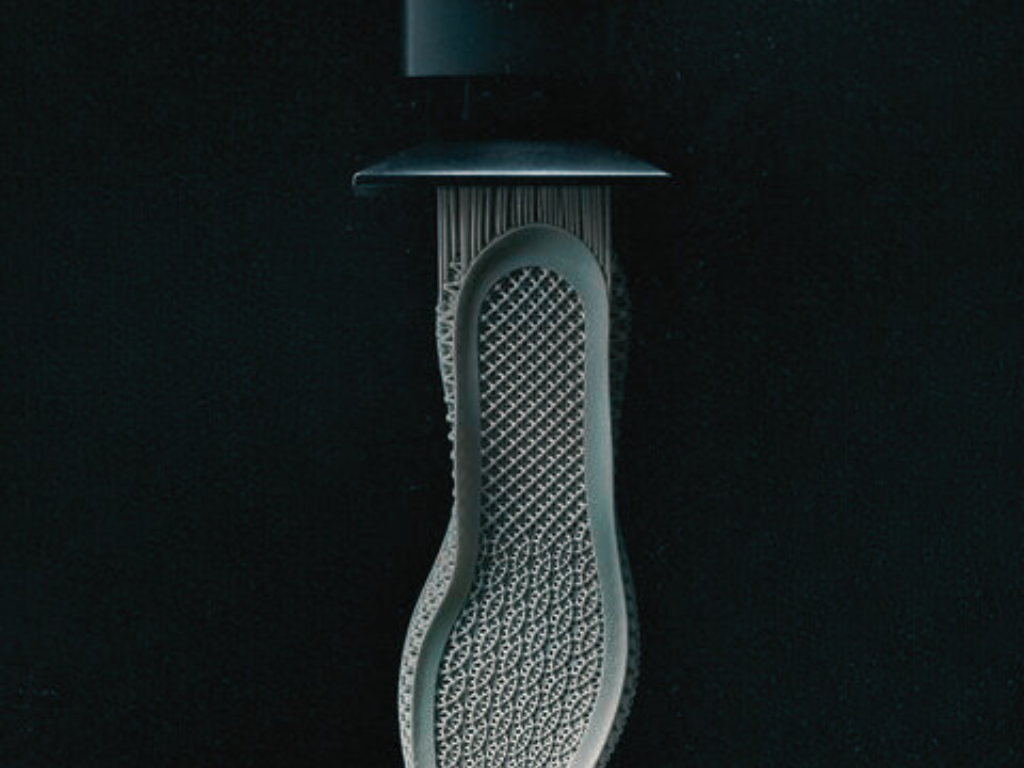

- Selective Laser Sintering (SLS) & Multi Jet Fusion (MJF): (min ±0.3 mm)

Using powder and laser or fusing lamps, these printers create complex shapes without needing supports, ideal for intricate geometries.

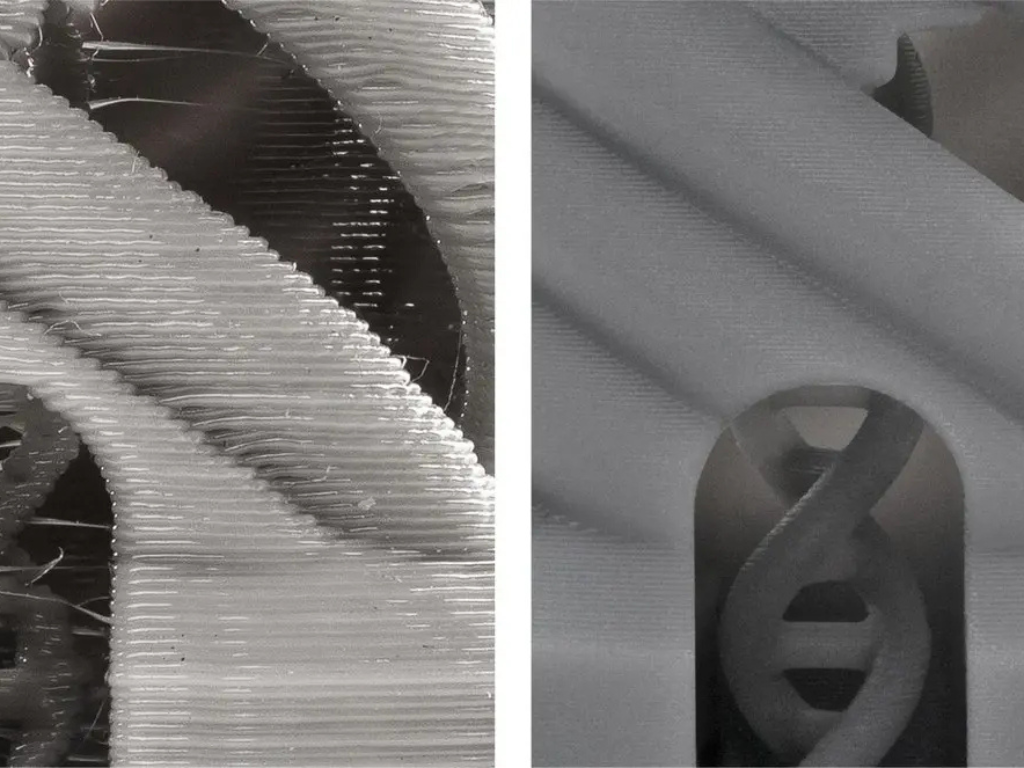

- Fused Deposition Modeling (FDM): (min ±0.5 mm)

In FDM (Fused Deposition Modeling) 3D printing, a nozzle melts and lays down thermoplastic material layer by layer to create an object. This method struggles with accuracy, making it hard to print small details. Additionally, parts may warp or shrink as they cool, causing deformation. While newer, more advanced FDM machines reduce these problems, they can be expensive. Despite improvements, the challenges of achieving high precision and avoiding deformation remain a concern, especially for budget-conscious users.

Consider 3D printing tolerances for successful production

Additive Manufacturing can streamline production across industries, from creating durable tires and surgical instruments to food-safe tableware and aircraft parts. Using 3D printing in your manufacturing process can lead to faster, more cost-effective production.

To maximize these benefits, pay close attention to design tolerances, as each 3D printing technology has specific size and dimension limitations. Understanding these restrictions ensures high-quality, precise results and helps avoid costly adjustments. Start integrating 3D printing into your process to enhance efficiency, reduce costs, and expand production capabilities.

Collaborate with 3D printing bureau to choose the best material and optimize build orientation for your project’s needs. Explore our 3D Printing Materials Guide to learn about various plastic and metal materials across technologies.

Discover more about additive manufacturing at projet.my. For assistance, reach out to our applications engineer at enquiry@projettech.com or +604-2858 335.