What is 3D Printing in the automotive industry?

In the world of automotive engineering, where accuracy, effectiveness, and new ideas are crucial, additive manufacturing (AM) has become a game-changer. Historically, the car industry mainly used subtractive manufacturing methods like milling and casting. But now, with technologies like 3D printing, a whole new range of possibilities has opened for automotive.

The Evolution of Additive Manufacturing in Automotive Engineering

Additive manufacturing in automotive engineering has undergone rapid evolution, transitioning from prototyping to the production of end-use parts. Initially utilized for rapid prototyping to test and validate designs before committing to costly tooling, 3D printing has advanced significantly. As materials have become more robust, automotive manufacturers have increasingly turned to additive manufacturing for functional parts production.

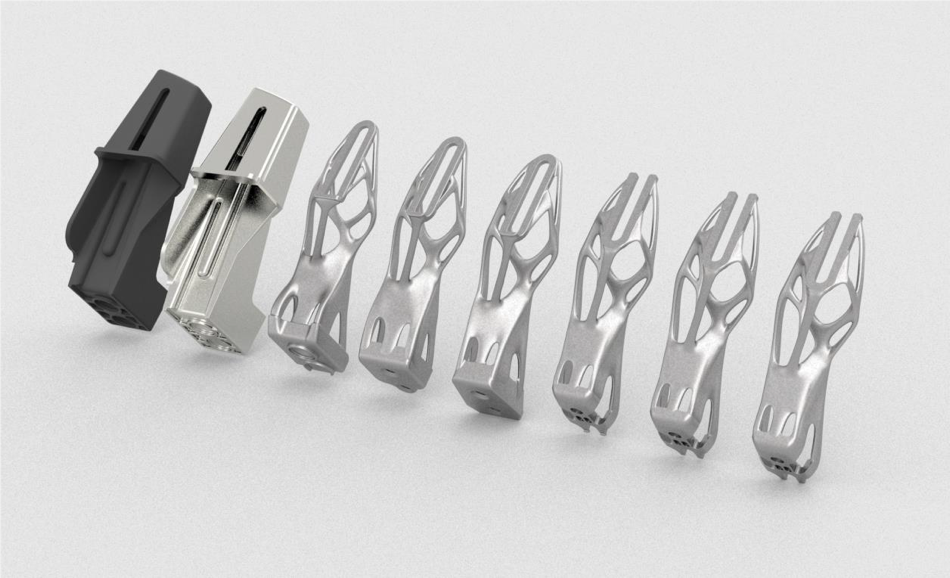

A key advantage of additive manufacturing lies in its capacity to produce complex geometries with intricate details, challenging or even impossible to achieve through traditional manufacturing methods. This capability empowers automotive engineers to design lightweight components without sacrificing strength or performance.

Benefits of Additive Manufacturing in Automotive Engineering

- Weight Reduction and Performance Enhancement

In automotive engineering, reducing weight while maintaining structural integrity is crucial for improving fuel efficiency and performance. Additive manufacturing allows engineers to design and produce lightweight components with optimized geometries, resulting in vehicles that are lighter, more fuel-efficient, and agile on the road.

- Design Freedom and Customization

With additive manufacturing, automotive designers have unparalleled design freedom. They can create intricate shapes, lattice structures, and complex geometries that were previously impossible or cost-prohibitive to manufacture. This flexibility enables customization at scale, allowing manufacturers to tailor components to specific vehicle models or even individual customer preferences. - Rapid Prototyping and Iteration

In the automotive industry, time-to-market is critical. Additive manufacturing accelerates the prototyping process by enabling rapid iteration and refinement of designs. Engineers can quickly produce functional prototypes for testing and validation, reducing lead times and speeding up the product development cycle.

Case Study: BMW’s Use of Additive Manufacturing

BMW is one of the automotive pioneers that has fully embraced additive manufacturing technology. The company utilizes 3D printing for various applications, including prototyping, tooling, and end-use part production.

One notable example is the BMW i8 Roadster, which features a metal 3D-printed bracket for mounting the convertible top. This lightweight component, made possible through additive manufacturing, contributes to the vehicle’s overall weight reduction and performance enhancement.

*Source: https://www.press.bmwgroup.com/global/article/detail/T0286895EN/a-million-printed-components-in-just-ten-years:-bmw-group-makes-increasing-use-of-3d-printing?language=en

Summary

As additive manufacturing advances, its impact on automotive engineering will grow. Future developments in materials, processes, and design software will expand 3D printing possibilities in the industry.

From mass customization to on-demand spare parts production, additive manufacturing has the potential to revolutionize vehicle design, manufacturing, and servicing. As automotive manufacturers adopt 3D printing technologies, we anticipate seeing innovative designs, improved performance, and sustainable solutions.

Projet considers 3D printing service as a key factor to the success of fast adoption of AM in manufacturing, We offer a range of capabilities, including 3D printing technologies such as FDM, SLA, and SLS, along with various solutions like rapid prototyping, mechanical design, and reverse engineering. We eagerly anticipate the opportunity to support your company in its processes.

Connect with Projet:

If you’ve had a positive experience with Projet that you’d like to share, please reach out to us at enquiry@projettech.com. We eagerly anticipate hearing from you.

For additional information, visit our website for comprehensive details about our services and contact information. Our friendly team is ready to assist you at any time.