- CompetenciesCompetenciesAdvanced technology

Other Manufacturing

- Services

- Industries

- MaterialsMaterialsOptions for every application

- 3D Printing Service

- CompanyCompanyThe catalyse

Learn how to choose the right heat-resistant plastic based on temperature limits, mechanical strength, and application requirements

Explore additive manufacturing solutions that enable customization, rapid iteration, and cost-effective production of tailored parts.

Explore methodologies for recreating and improving components, from 3D scanning and CAD modeling to final production.

Learn how additive manufacturing overcomes major tooling issues—cutting delays, reducing costs, and enabling rapid design changes.

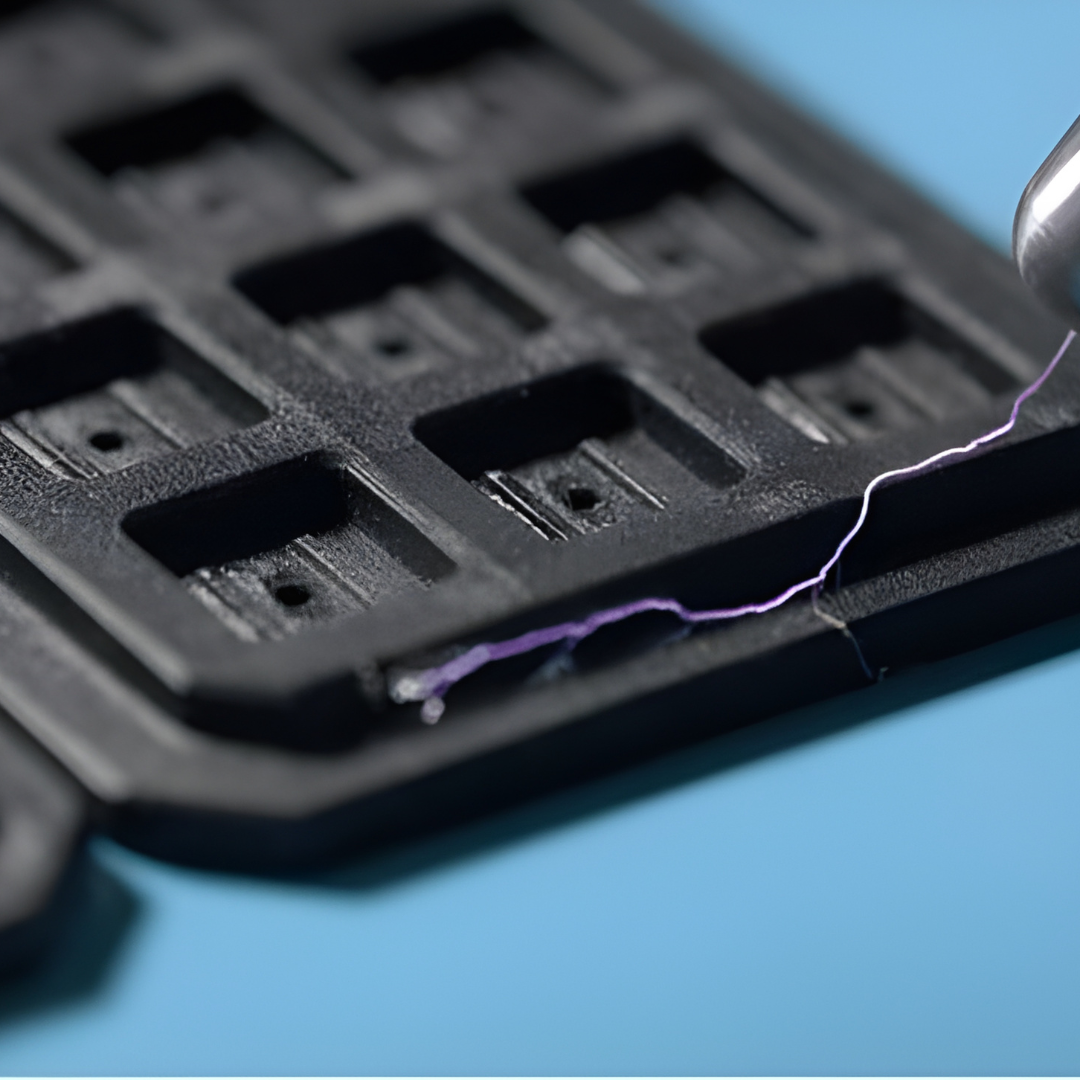

Discover ESD-safe FDM material designed for electronics, tooling, and industrial applications requiring static protection and durability.

Learn when outsourcing 3D printing saves time, money, and stress versus in-house production. Find the best approach for your business.

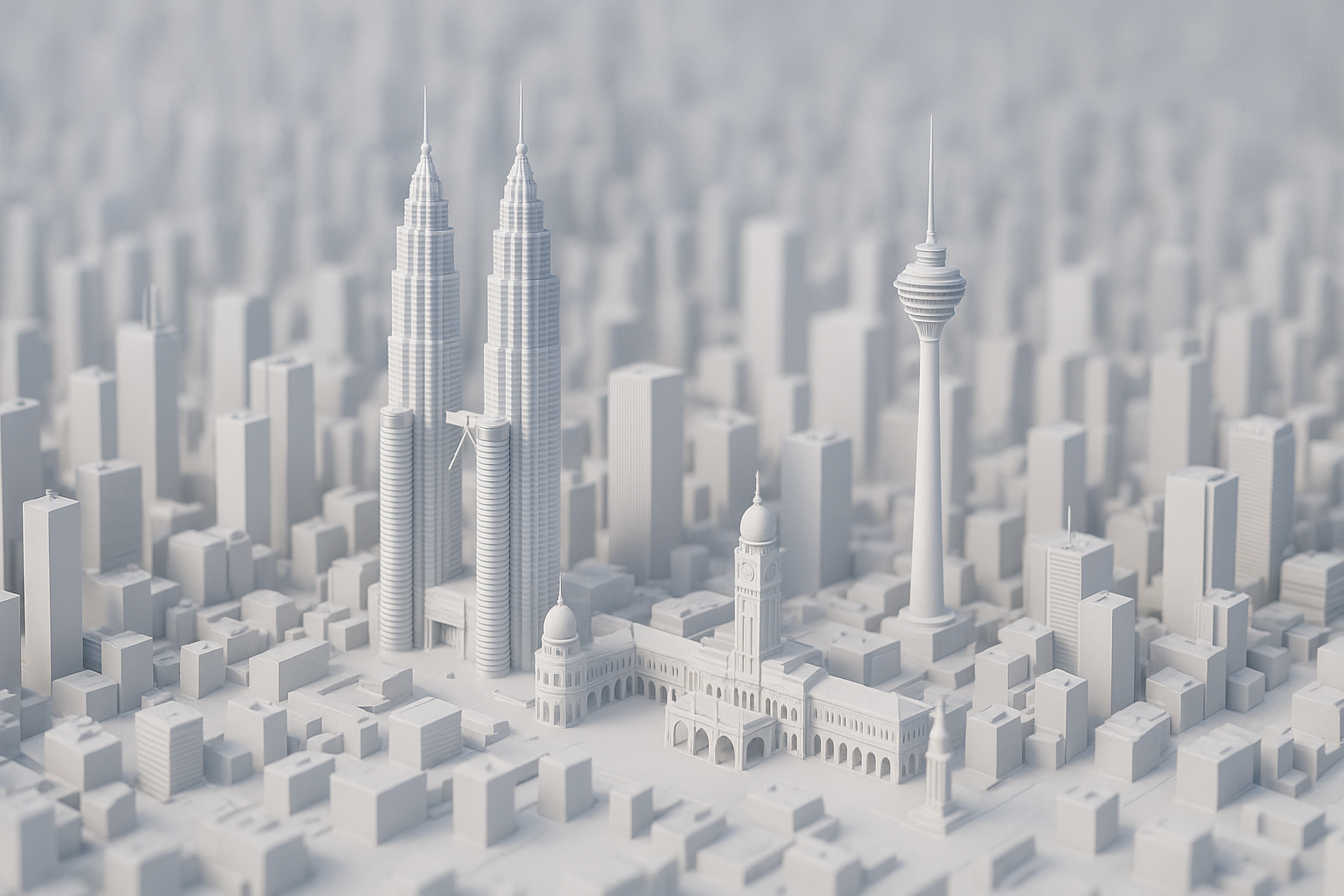

Discover how scale models help businesses visualize ideas, validate designs, and impress clients for faster decision-making.

Explore high-performance thermoplastics that meet medical standards for safety, strength, and sterilization compatibility.

Explore common autoclave-compatible materials that withstand high heat and pressure for sterilization in medical, lab, and industrial use.

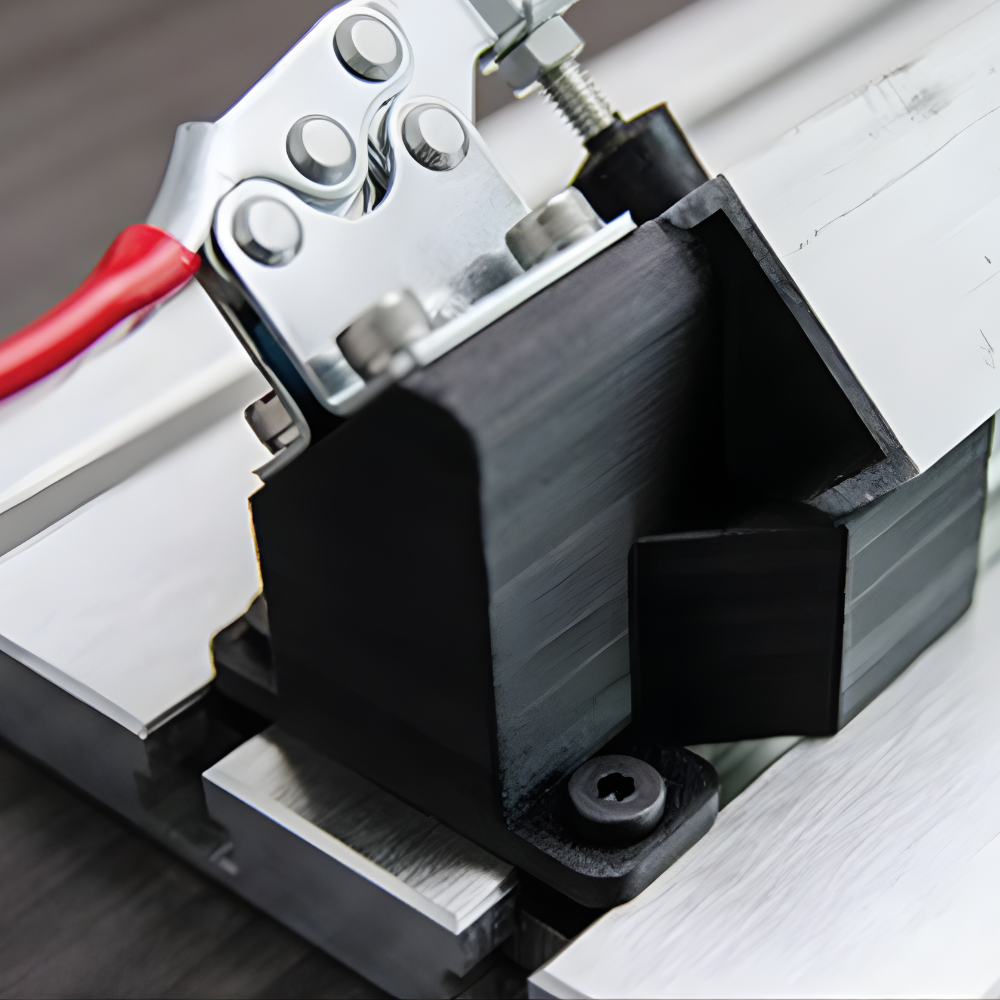

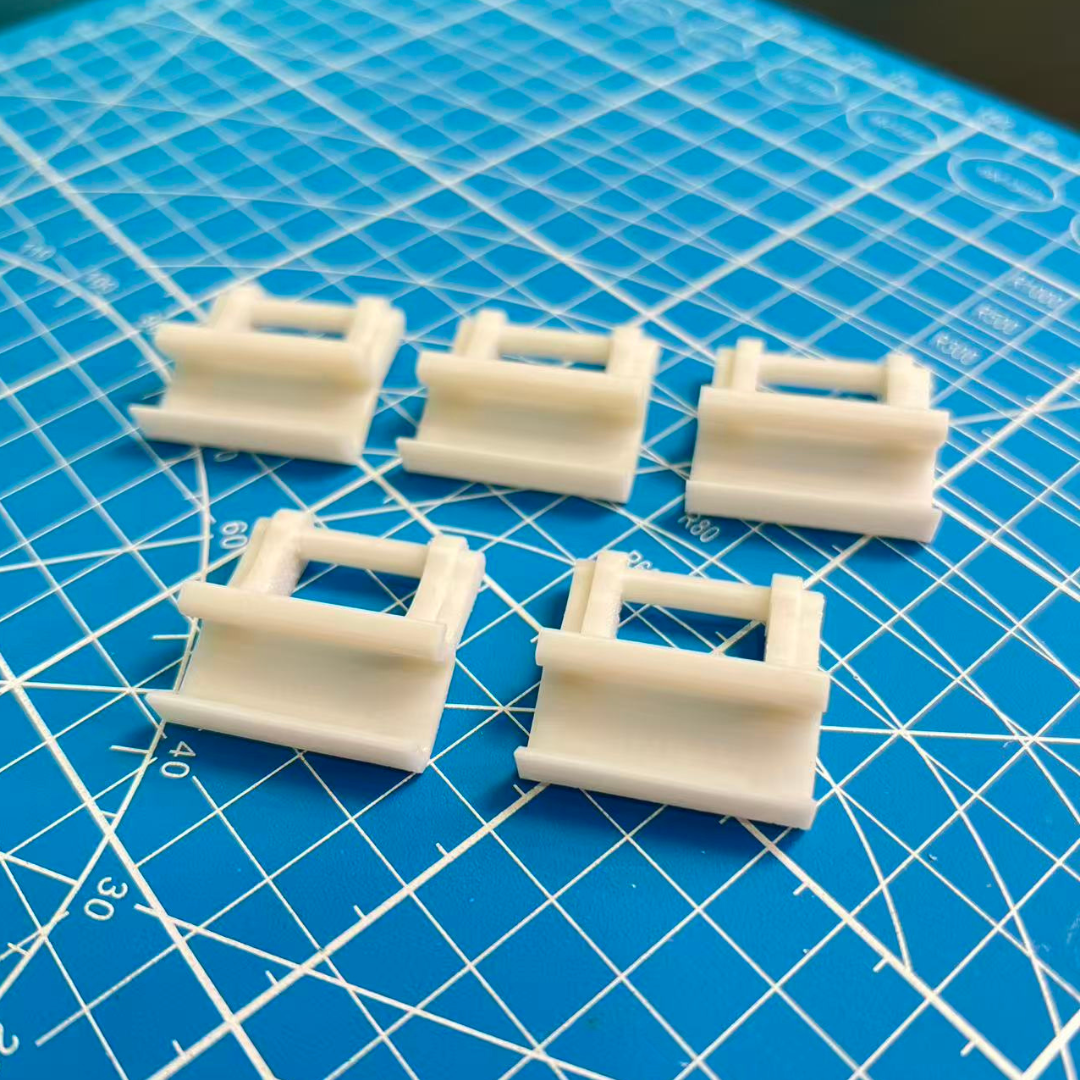

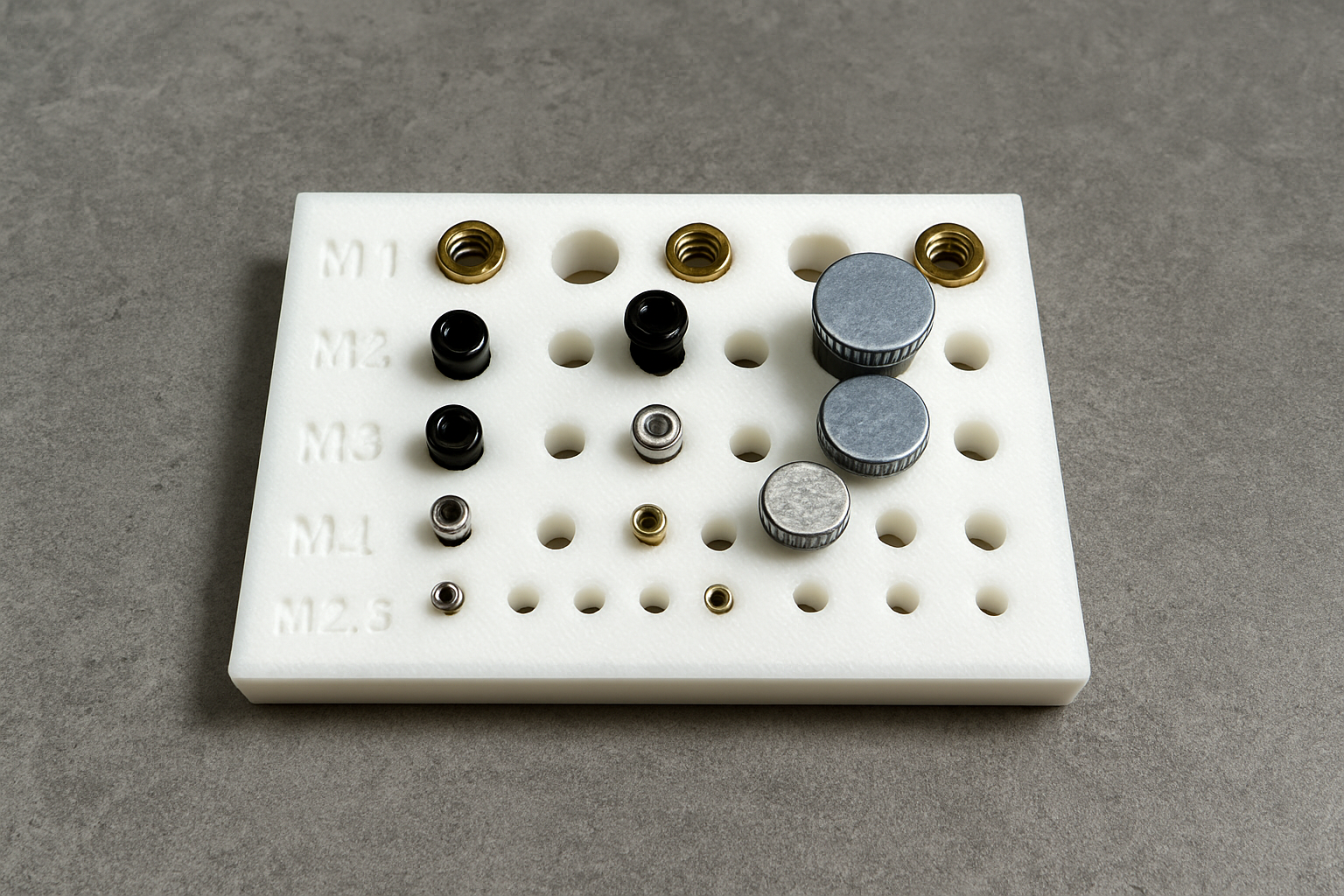

Discover methods for threading 3D-printed parts—heat set inserts, press fit inserts, and tapping for durable, precise assemblies.