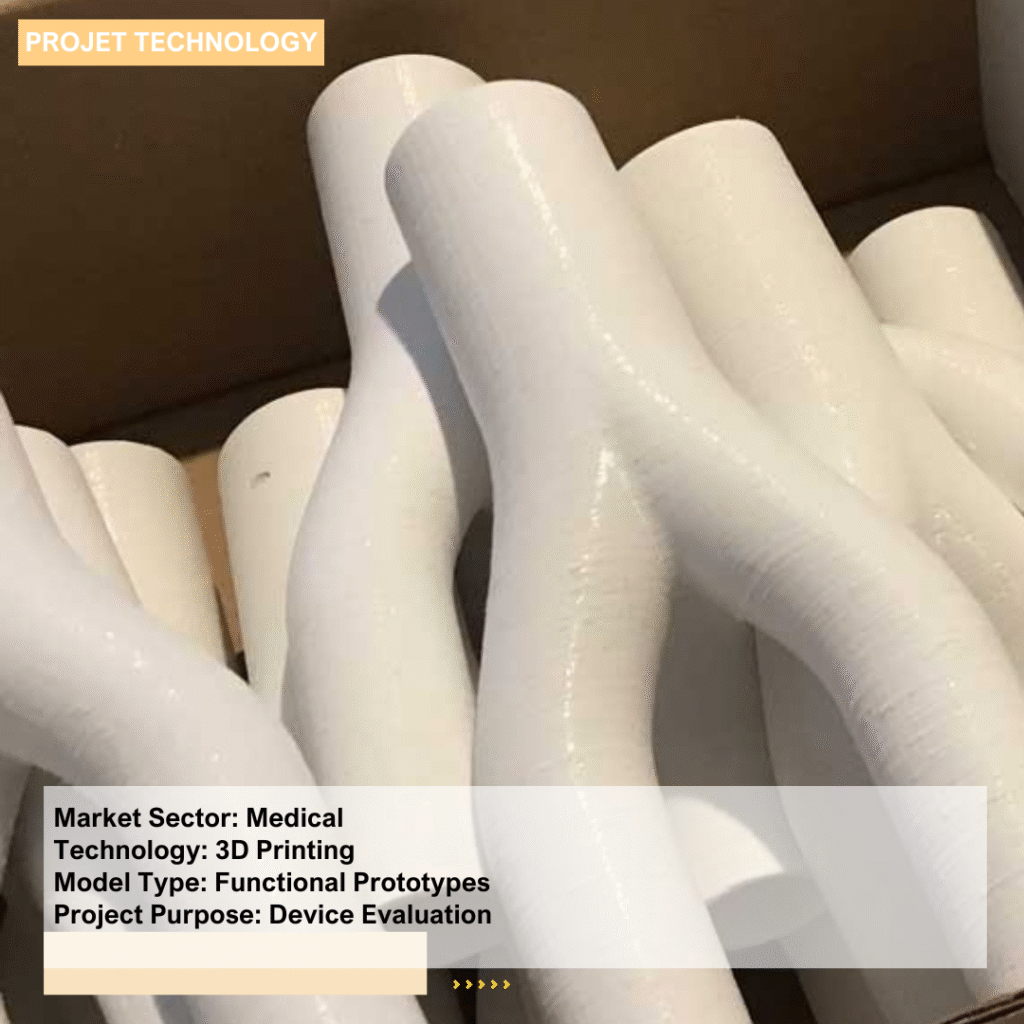

Discover how 3D printing enabled rapid prototyping for a critical device evaluation, cutting costs & time. Real-world case study with measurable results.

That Morning Call:

“We need functional prototypes for device testing by next week—with engineering-grade materials.”

That was Joshua, an R&D engineer in the medical industry, facing every engineer’s nightmare:

- Clinical trials were stalled, risking 6-figure delays

- Traditional prototyping was too slow where machining and outsourcing would take more than 3 weeks

He discovered Projet through word of mouth from another department, as they were already using 3D printing to manufacture jigs for their production line.

The Solution: Engineering-Grade 3D Printing

Within 24 hours, we assessed the requirements and proposed:

- Functional prototypes using engineering grade material

- Complex geometries impossible with traditional machining.

- Turnaround: 7 days—from design to delivery.

The Result: Trials Back on Track

Day 1: Final CAD files submitted.

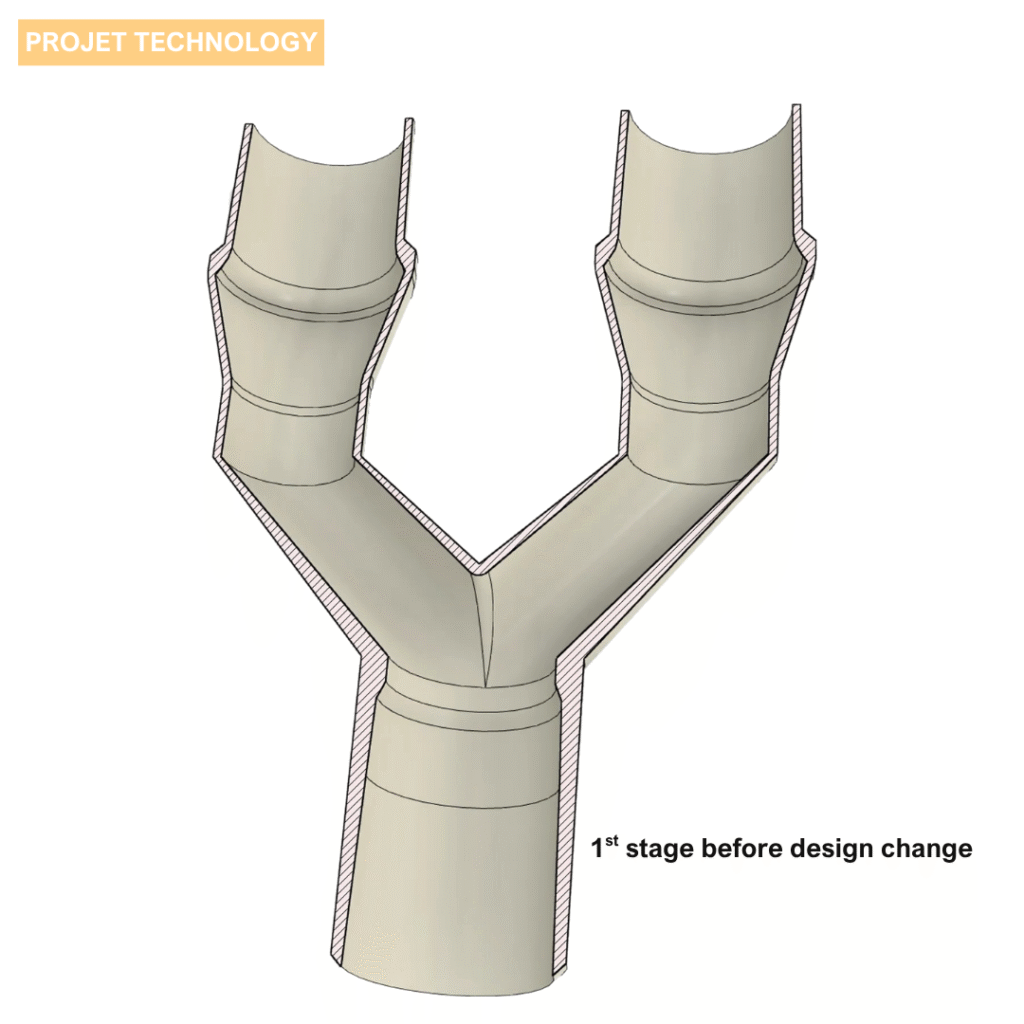

Day 2: Design improvement with design change

Day 4: First prototypes printed, post-processed for strength.

Day 7: Fully functional parts delivered—matching final product performance.

Why It Worked

✔ Speed: 7 days vs. 3 weeks.

✔ Precision: Complex internal channels printed flawlessly.

✔ Cost savings: Avoided six-figure delays.

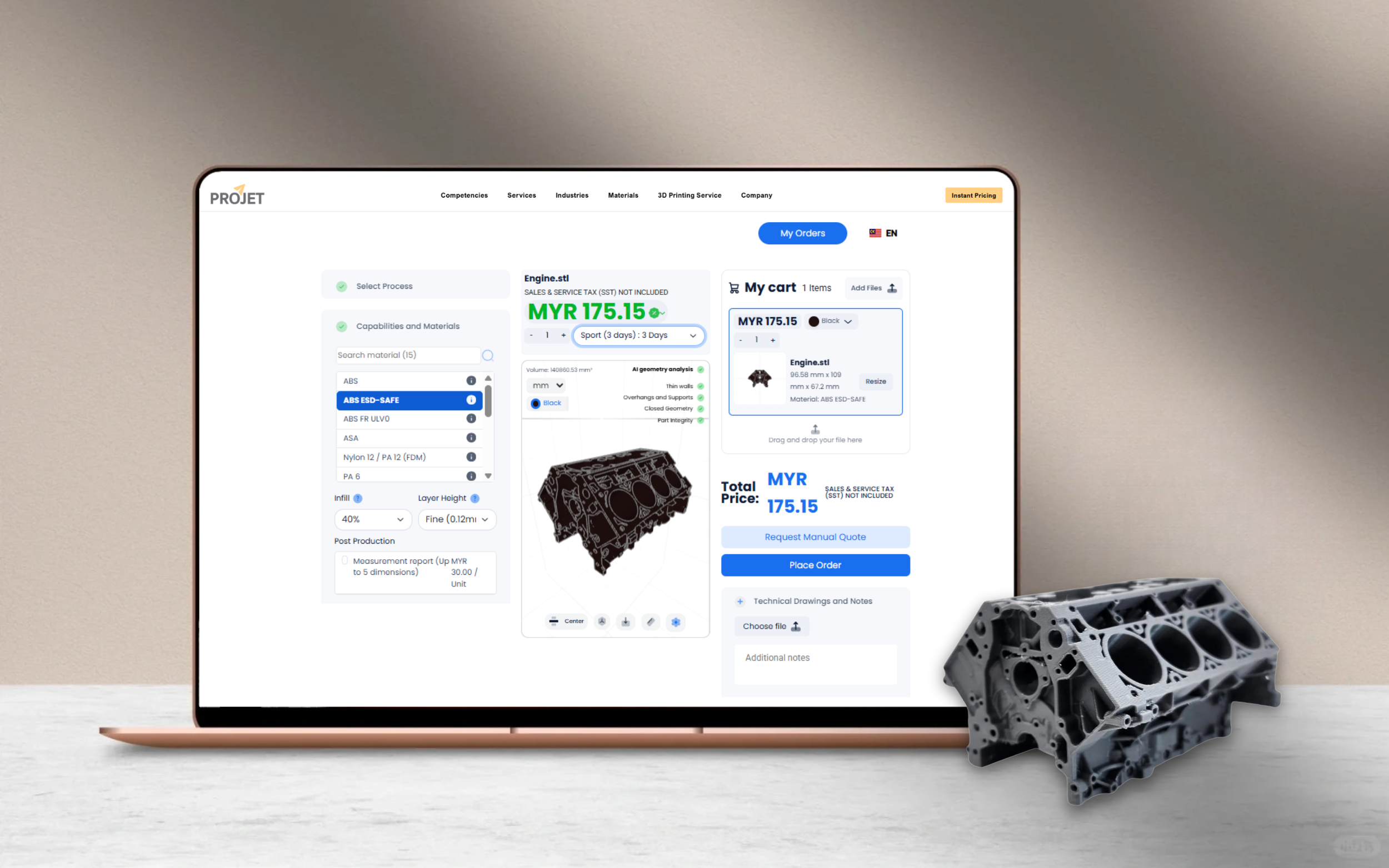

3D Printing Service Malaysia , 3D Printing service Singapore , 3D Printing service KL , 3D Printing service Selangor, 3D Scanning Malaysia

3D Printing Services

Instant Price