Safe. Sterile. Trusted for Over a Century.

A Quick History of Sterilization

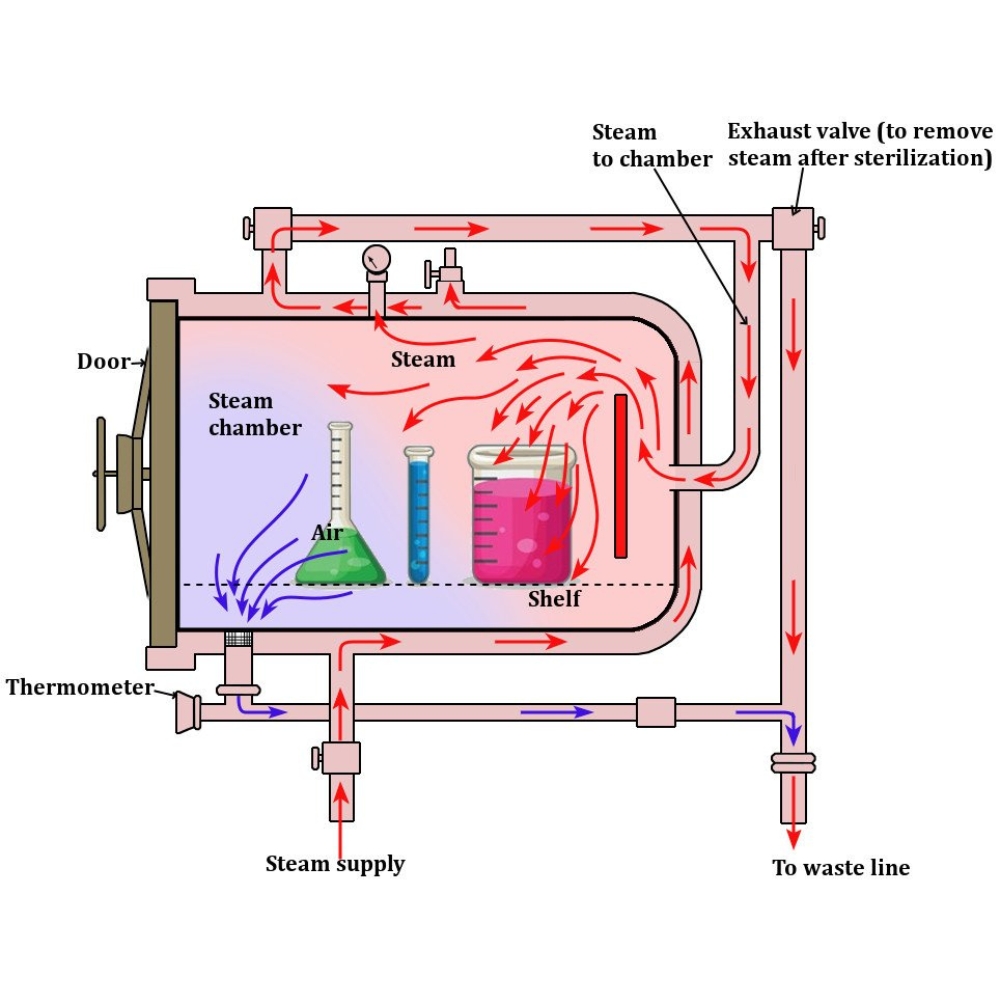

Feeling nervous about an upcoming medical procedure? That’s understandable — but rest assured, the instruments used will be completely sterile and free of microorganisms. The importance of sterilization has been recognized for over 150 years. In 1879, French microbiologist Charles Chamberland invented the first autoclave, a breakthrough that made steam-based sterilization possible.

How Autoclaves Work

An autoclave works much like a pressure cooker. Instruments are placed inside a sealed chamber where air is removed. Then, pressurized steam at 250°F (121°C) or higher is applied for 30 to 60 minutes.

While other sterilization methods exist—such as dry heat, radiation, UV light, or gas-based sterilization—autoclaving remains one of the most common and effective methods in the medical, dental, and research fields.

What Works (and What Doesn’t) in an Autoclave

Not every material can handle the heat and pressure of an autoclave. Let’s look at which ones make the cut.

Materials to Avoid:

These materials typically warp, melt, or lose strength during autoclaving:

Polyethylene (PE) – includes LDPE and HDPE variants

Polymethyl methacrylate (PMMA) – better known as acrylic

Polystyrene (PS)

Polyvinyl chloride (PVC)

Autoclave-Safe Materials:

These materials perform well under autoclave conditions and are ideal for sterilizable parts:

Polyamide (Nylon or PA) – Strong, wear-resistant, and durable.

Polypropylene (PP) – Affordable and heat-resistant, commonly used in labware.

Polycarbonate (PC) – Clear and tough; a good alternative to acrylic.

Polyoxymethylene (POM/Acetal/Delrin) – Offers strength, stiffness, and low friction.

Polytetrafluoroethylene (PTFE or Teflon) – Excellent chemical resistance and stability.

Polyetheretherketone (PEEK) – High-performance thermoplastic used in medical implants and precision components.

Silicone & Liquid Silicone Rubber (LSR) – Flexible, biocompatible, and autoclavable.

Polyphenylene Sulfide (PPS), Polysulfone (PSU), and Polyether Sulfone (PES) – Tough, high-temperature polymers suitable for machining, molding, or 3D printing.

Autoclave-Safe Metals

While plastics are versatile, metals remain essential for medical and industrial applications that demand strength and precision.

Stainless Steel (304, 316, 304L, 316L) – Corrosion-resistant and widely used in surgical tools, implants, and hospital equipment.

316L Stainless Steel – Preferred for implants and devices inside the body due to its superior corrosion resistance.

Cobalt Chrome (CoCr) and Titanium (Ti-6Al-4V) – Ideal for orthopedic parts requiring high strength and fatigue resistance.

To maximize corrosion resistance, passivation (using nitric or citric acid) is essential. This process removes surface iron and forms a protective oxide layer.

Aluminum can also be used if it’s anodized with a Type II (sulfuric acid) or Type III (hard coat) medical-grade finish. Similarly, steels like 1018 or 4140 can be protected through chrome or nickel plating to prevent corrosion.

Choosing the Right Material for Sterilization

In the medical and laboratory industries, every material and process must meet strict performance and sterilization standards. Selecting the right material ensures safety, longevity, and compliance with regulatory requirements.

At Projet, we understand the unique challenges of producing autoclave-safe parts—from material selection to 3D printing and finishing. Our team helps engineers and designers choose the most suitable materials for their applications, ensuring that every part performs under pressure.

Projet: Your Partner in Autoclave-Safe Manufacturing

Whether you need precision metal components or durable, sterilizable plastics, Projet is your trusted partner for medical, lab, and industrial manufacturing.

We combine advanced 3D printing, machining, and molding capabilities with deep material expertise to deliver components that meet your sterilization and performance requirements.

Talk to Projet today to find the best autoclave-compatible materials for your next project — and manufacture with confidence.

3D Printing Services

Instant Price