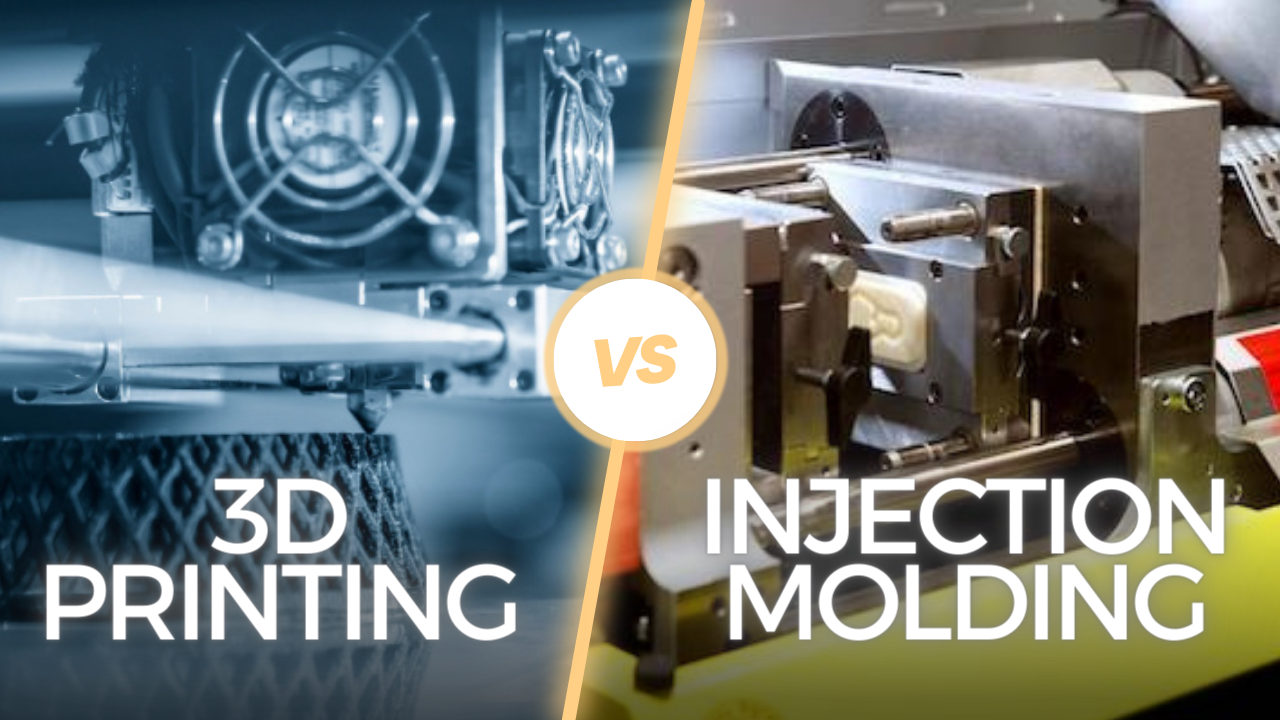

For many years, injection moulding has led the way as a technique for producing three-dimensional plastic products that are used across every sector and country in the world.

However, just as technology advances in all areas, so the advent of 3D printing has given manufacturers and consumers a greater choicer when it comes to deciding how to make plastic products. Both methods have their distinct advantages and disadvantages and are used for different products, applications, and circumstances.

| 3D Printing | Injection Molding |

Design Changes | Design changes can be implemented immediately with minimal downtime. | Design changes are costly and time consuming. |

Lead Time | Very Short | Longer lead times due to mold fabrication and setup processes |

Tooling Costs | No tooling costs | Yes, for mold creation |

Material Choices | Offers a wide range of material options | Limited to materials compatible with injection molding processes. |

Design Versatility | Well-suited for complex geometries or intricate designs. | More cost-effective for parts with relatively simple geometries. |

Customization | Allows for tailored customization of individual parts. | Limited customization; molds are expensive and inflexible. |

Summary

Projet considers 3D printing service as a key factor to the success of fast adoption of AM in manufacturing, We offer a range of capabilities, including 3D printing technologies such as FDM, SLA, and SLS, along with various solutions like rapid prototyping, mechanical design, and reverse engineering. We eagerly anticipate the opportunity to support your company in its processes.

Connect with Projet:

If you’ve had a positive experience with Projet that you’d like to share, please reach out to us at enquiry@projettech.com. We eagerly anticipate hearing from you.

For additional information, visit our website for comprehensive details about our services and contact information. Our friendly team is ready to assist you at any time.