Customization has become a defining trend in today’s market. Customers increasingly value uniqueness and expect products that reflect their individual preferences, functional requirements, or operational constraints. This shift raises an important question for manufacturers: how can standardized products be adapted to meet highly specific customer needs without sacrificing efficiency or profitability?

The answer lies in the evolution of manufacturing technologies and the growing demand for flexible production models. Customization, in its modern sense, refers to tailoring products or components to specific requirements while still leveraging scalable manufacturing processes. Among the available technologies, additive manufacturing (AM), commonly known as 3D printing, has emerged as a powerful enabler of this transformation.

In this article, we explore what customization truly means, why it is increasingly relevant to businesses, and how additive manufacturing makes customized production both practical and economical. We will also highlight a real-world example of a customized 3D printing project.

What Is Customization?

Customization allows products to be modified—or entirely designed—according to individual customer requirements. Rather than offering a one-size-fits-all solution, manufacturers can adapt dimensions, geometries, materials, or functional features to meet precise specifications.

Additive manufacturing provides a clear and practical interpretation of customization. Using digital design tools, customer inputs can be directly translated into 3D models and produced without the need for complex retooling. This approach enables customers to participate in the creation process, ensuring that the final product aligns closely with their expectations.

At its core, customization integrates customer involvement into the production workflow while maintaining the efficiency of modern manufacturing systems.

Why Is Customization Relevant to Business?

Customer expectations are continuously evolving. Today’s buyers are less willing to accept standardized products if those products do not fully meet their needs. As a result, reliance on traditional mass production alone is becoming increasingly risky.

From the customer’s perspective, customization offers greater control over product design, functionality, and aesthetics. This leads to improved satisfaction, stronger brand loyalty, and a higher perceived value of the product.

For manufacturers, customization presents strategic advantages as well. Producing parts on demand reduces the need for large inventories, minimizes waste, and lowers the risk of overproduction. In contrast, mass production of standardized components often results in excess stock, storage costs, and material waste—especially in markets with fluctuating demand.

Why Use Additive Manufacturing for Customization?

Additive manufacturing, often called 3D printing, is a good choice for customization because it is based on digital designs. Unlike traditional manufacturing, it does not need molds, special tools, or expensive equipment for each new design. This saves both time and money, especially when making different versions of a product.

Once the digital system is set up, specific customer needs can be added directly to the design file and sent to production right away. Changes or personalized features can be made easily without slowing down production or increasing setup costs.

Because of this, additive manufacturing works well not only for single custom parts, but also for small to medium batches of customized products.

Advantages of Additive Manufacturing for Customization

One of the biggest benefits of additive manufacturing, also known as 3D printing, is that it does not require expensive molds or special tools. Because of this, manufacturers can change designs for different customers without spending extra money or slowing down production.

Designs can be easily reused and adjusted to create many variations of the same product. This makes it possible to produce customized items on a larger scale, rather than making only one standard product for everyone. Companies can also react quickly to customer feedback or changes in the market.

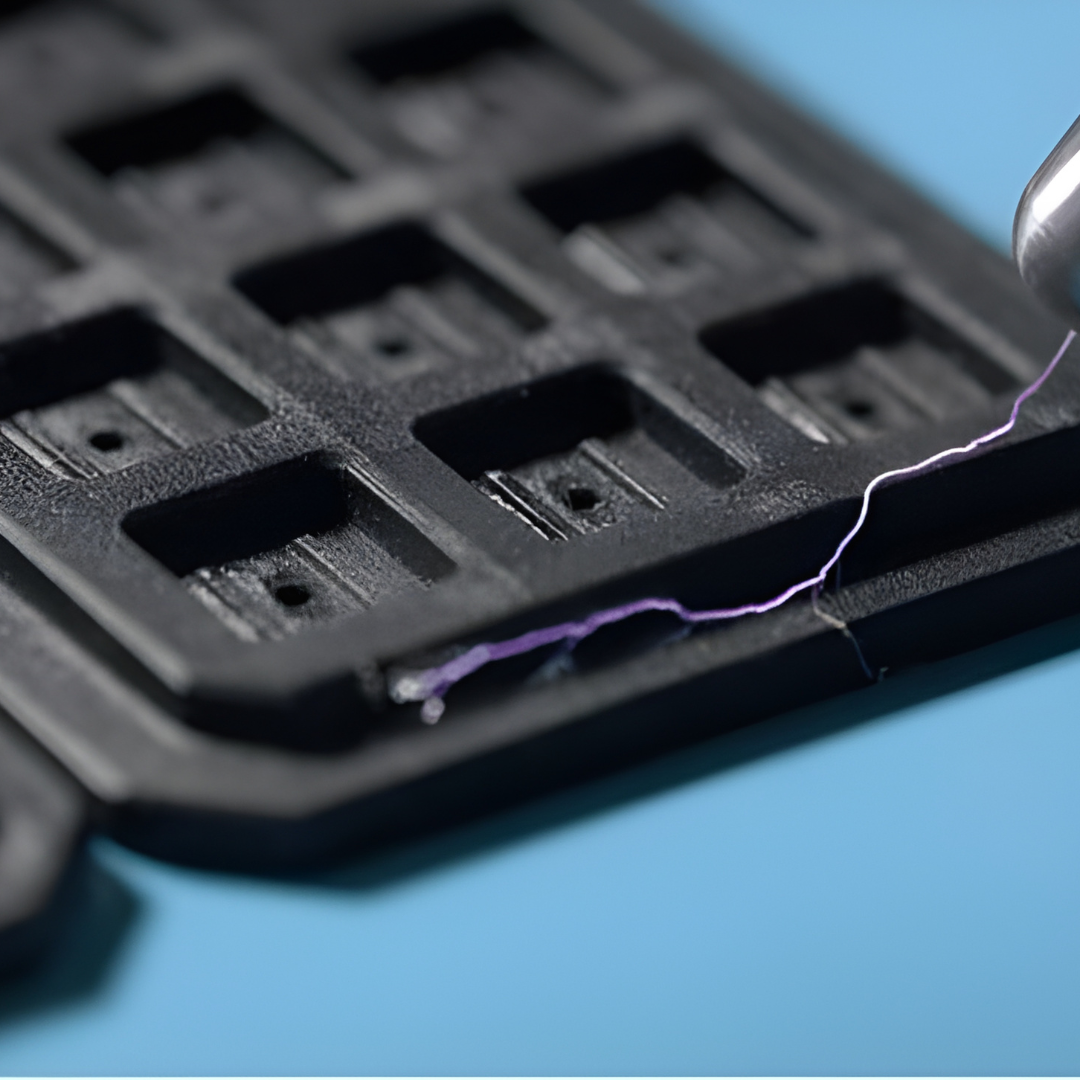

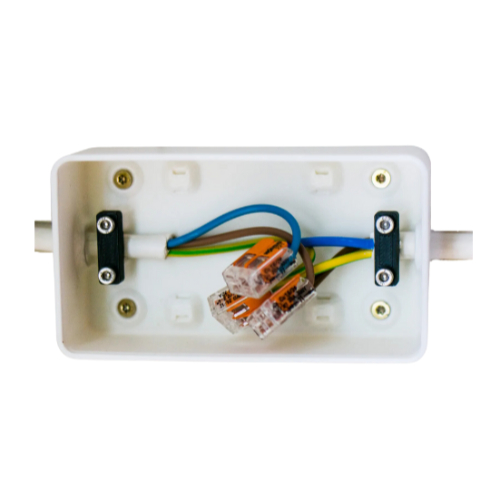

Another advantage is the wide range of materials that can be used, including plastics and strong metals. This allows customized parts to be made for many industries, such as automotive, aerospace, industrial equipment, and everyday consumer products.

Overall, additive manufacturing makes it possible to offer customized products quickly and efficiently, without increasing costs or delaying delivery.

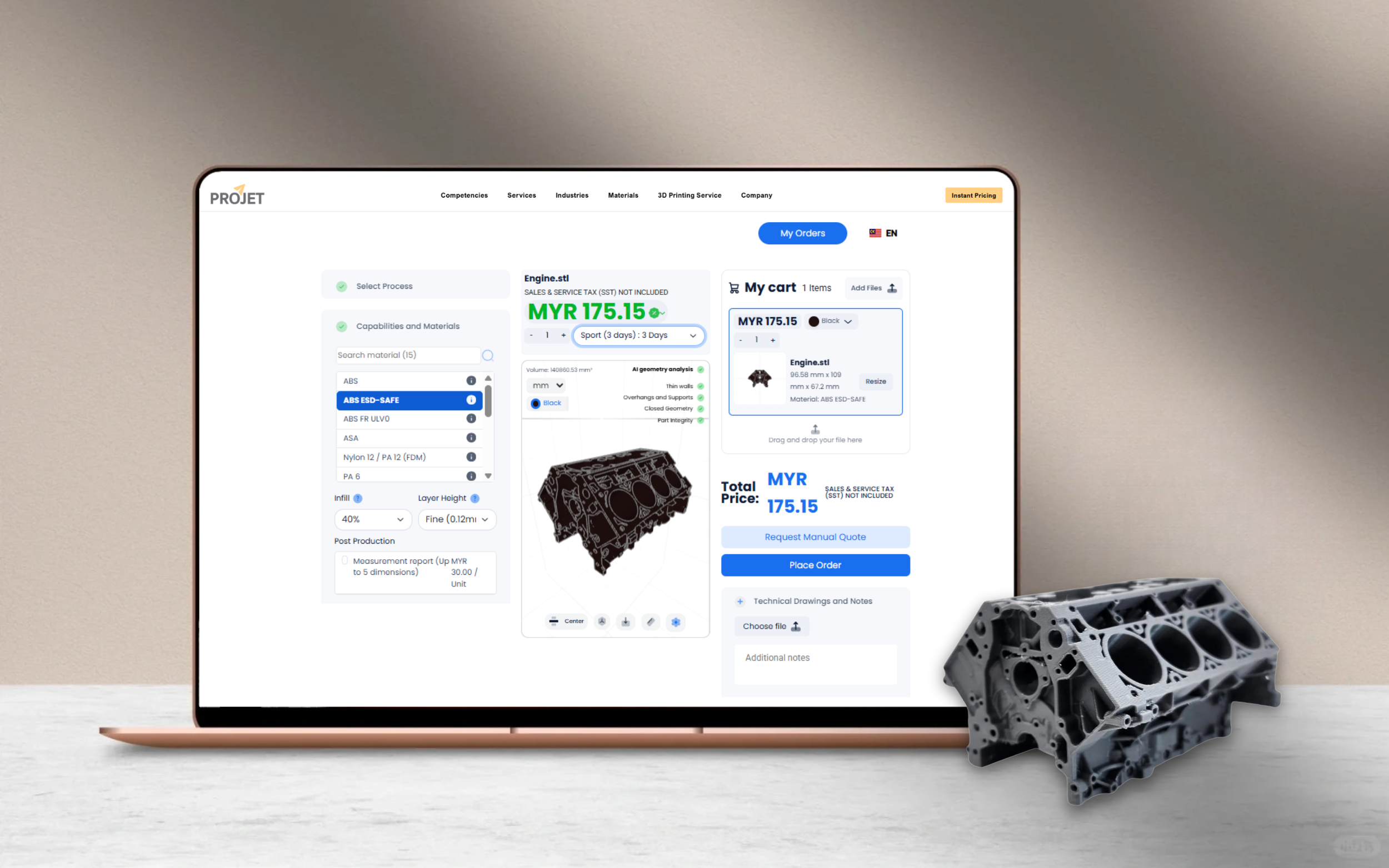

Example of a Customized 3D Printing with Projet

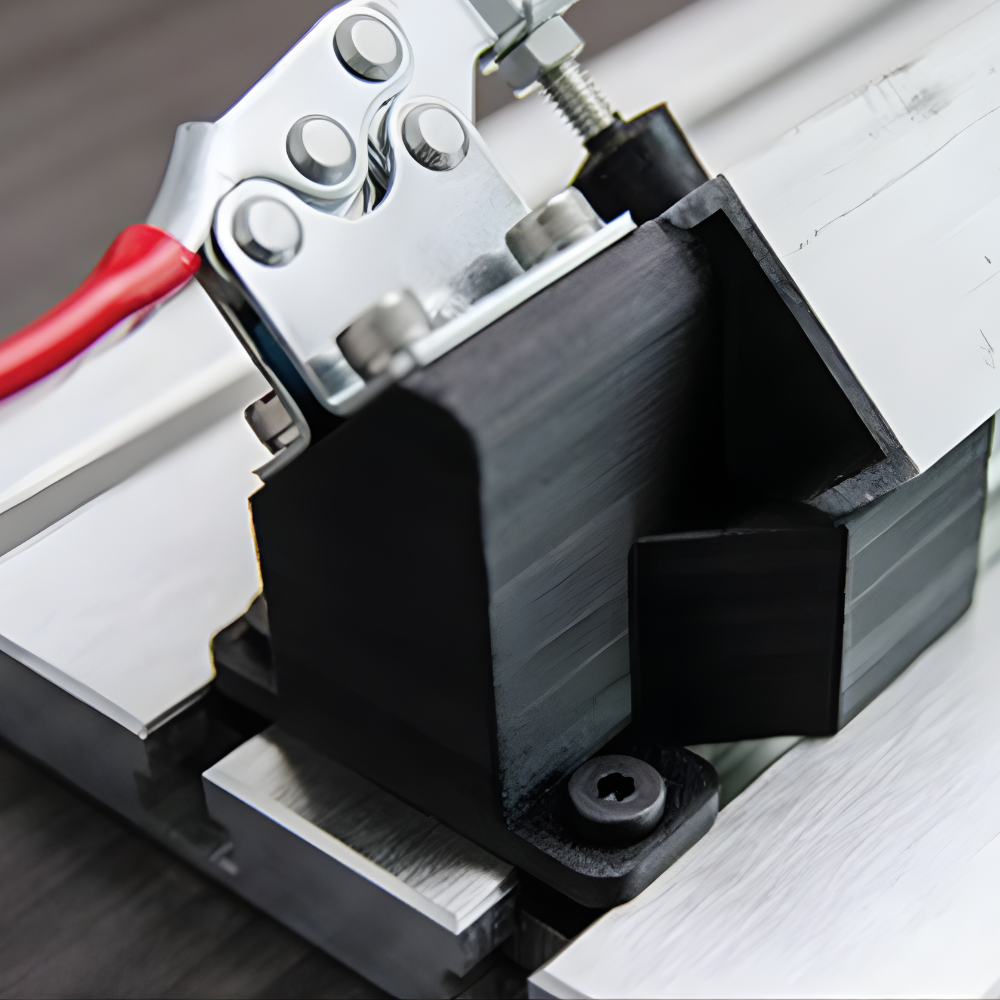

Many companies across industries have already recognized the value of additive manufacturing for customization. One representative example involves a customized automotive exhaust pipe developed for a client’s machinery assembly trial.

The exhaust system consisted of three integrated components: a connecting rod, a gas chamber, and the exhaust outlet. Using additive manufacturing technology from Projet, we provided a complete end-to-end solution—from initial design optimization to final part production.

By leveraging 3D printing, the client was able to quickly validate the design, test fitment during assembly, and reduce development time compared to traditional manufacturing methods. This project demonstrates how additive manufacturing enables rapid customization while maintaining functional performance and production efficiency.

3D Printing Service Malaysia , 3D Printing service Singapore , 3D Printing service KL , 3D Printing service Selangor, 3D Scanning Malaysia

Why Partner with Projet ?

Selecting the right manufacturing technology is important—but choosing the right manufacturing partner is what truly drives success. Companies across the electronics, automotive, consumer products, aerospace, and medical industries trust Projet because we are more than just a supplier; we are a dedicated partner in their success.

Here’s what sets us apart:

A True One-Stop Solution

We provide a seamless experience by offering a comprehensive suite of manufacturing services under one roof. This integrated approach streamlines your supply chain and simplifies the journey from concept to a market-ready product.

Engineering Expertise You Can Count On

Our experienced engineering team acts as a dedicated extension of your own. We excel at solving complex manufacturing challenges and collaborate closely with you to optimize your designs for quality, cost-effectiveness, and manufacturability.

Flexible Production Volumes to Match Your Needs

Whether you require a single prototype or a high-volume production run, our manufacturing capabilities are designed to scale with your demands. We support your product’s entire lifecycle, from initial launch to full-scale production.

Rapid Turnaround for a Faster Time-to-Market

In today’s fast-paced market, speed is a crucial advantage. We deliver fast, transparent quotes and pride ourselves on our rapid turnaround times, helping you get your innovative products to market sooner.

3D Printing Services

Instant Price