Choosing the right finish for your product is a critical decision. Both painting and powder coating have their own unique strengths and weaknesses, leaving many to wonder: which one is the best choice? An incorrect selection can lead to poor performance, higher maintenance costs, and a shorter product lifespan.

Don’t worry. In this comprehensive guide, we’ll break down the key differences between powder coating and painting, looking at everything from performance and cost to environmental impact and applications. By the end, you’ll have the knowledge to confidently choose the best finish for your needs

What Is Powder Coating?

Powder coating is a dry finishing process that has become increasingly popular for its durability and high-quality appearance.

Instead of liquid paint, this method uses a fine powder typically made from a blend of resins, pigments, and additives. This powder is applied to a metal part and then cured with heat, creating a tough, uniform, and attractive finish. The typical thickness for a powder-coated finish is between 60 and 120 μm

Types of Powder Coating

There are two main categories of powder coating, each with its own unique properties:

Thermoset: This is the most common type of powder coating. During the curing process, the powder undergoes a chemical reaction that creates strong, permanent bonds. The resulting finish is extremely durable and resistant to heat and chemicals, making it ideal for automotive parts, industrial equipment, and outdoor applications.

Thermoplastic: Unlike thermoset powders, thermoplastic coatings do not form chemical bonds. They simply melt and flow over the part when heated and can be remelted and reshaped. This makes them a good choice for applications that require a thicker, more flexible coating, such as playground equipment, handrails, and wire baskets.

What Is Painting?

Painting is a traditional finishing process that has been used for centuries to protect and decorate a wide variety of materials, including metal, wood, and plastic. Liquid paint is a mixture of pigments, binders, and solvents. When applied to a surface, the solvents evaporate, leaving behind a solid film that provides color and protection. The thickness of a painted finish typically ranges from 80 to 180 μm.

Powder Coating vs. Painting: A Head-to-Head Comparison

| Feature | Powder Coating | Painting |

|---|---|---|

| Durability | Very high. Resistant to chipping, scratching, fading, and corrosion. | Moderate. More prone to chipping, scratching, and fading over time. |

| Finish Thickness | Thicker, uniform finish achieved in a single coat. | Thinner finish, often requiring multiple coats. |

| Color Options | Wide range of standard colors; custom colors may be more complex. | Virtually unlimited color options with easy custom matching. |

| Environmental Impact | Eco-friendly. No VOCs or harmful solvents; overspray can be recycled. | Contains VOCs and solvents that may impact the environment. |

| Initial Cost | Higher upfront investment for equipment. | Lower initial cost for basic setup. |

| Long-Term Cost | More cost-effective due to high durability and minimal maintenance. | Lower upfront cost but higher long-term maintenance and repainting needs. |

Which Finish is Better for Your Project?

The best choice for your project will depend on your specific needs and priorities.

Choose Powder Coating if:

- Durability is your top priority. Powder coating is ideal for products that will be exposed to harsh conditions, heavy use, or outdoor environments.

- You need a thick, uniform finish.

- Environmental impact is a concern.

Choose Painting if:

- You need to coat heat-sensitive materials like wood or plastic.

- You require a very thin finish.

- You need to match a specific custom color.

- Your budget for initial setup is limited.

Both powder coating and painting are excellent finishing options, but they are not interchangeable. By understanding the key differences between the two, you can make an informed decision that will result in a high-quality, long-lasting finish for your product.

3D Printing Service Malaysia , 3D Printing service Singapore , 3D Printing service KL , 3D Printing service Selangor, 3D Scanning Malaysia

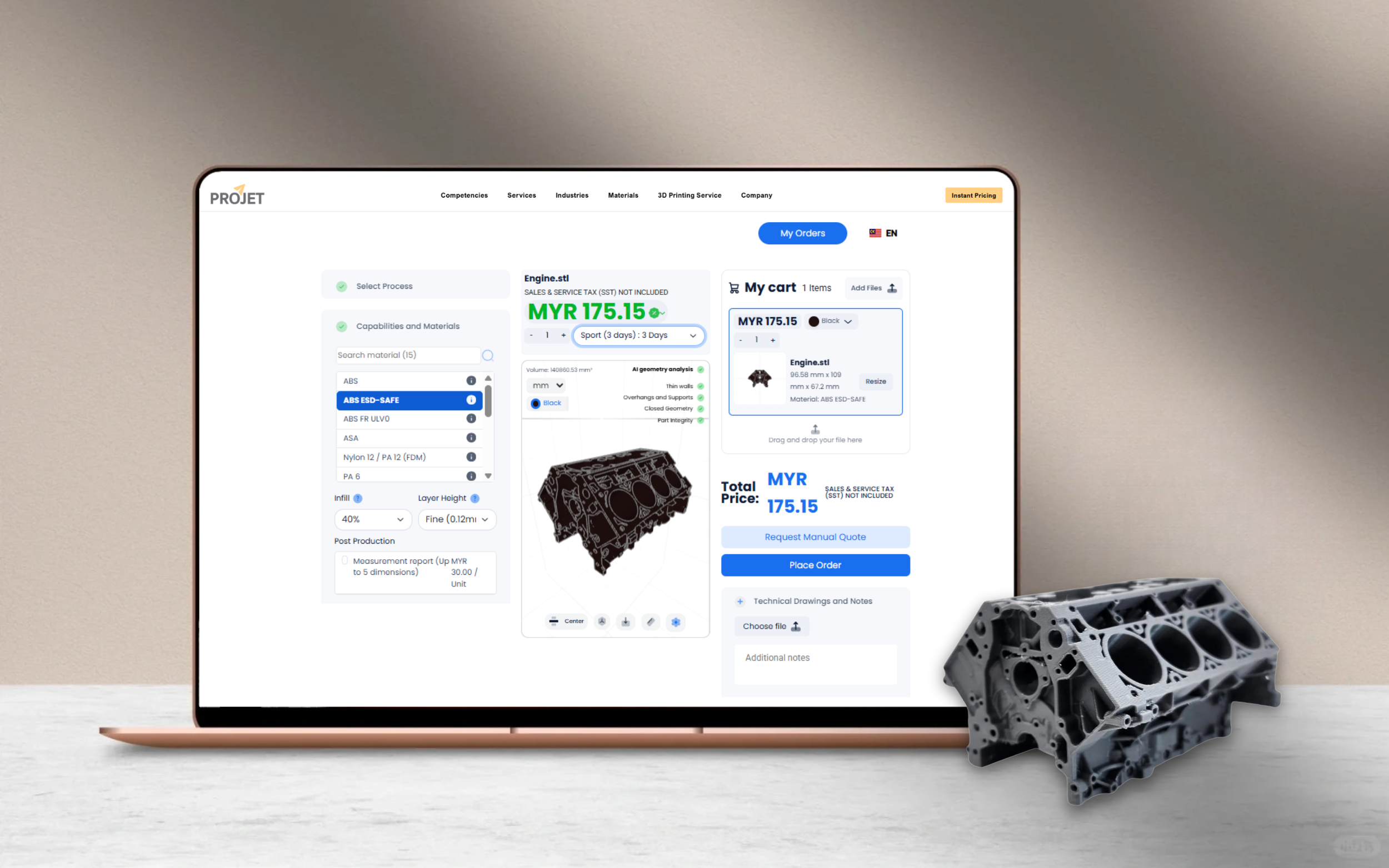

Why Partner with Projet ?

Selecting the right manufacturing technology is important—but choosing the right manufacturing partner is what truly drives success. Companies across the electronics, automotive, consumer products, aerospace, and medical industries trust Projet because we are more than just a supplier; we are a dedicated partner in their success.

Here’s what sets us apart:

A True One-Stop Solution

We provide a seamless experience by offering a comprehensive suite of manufacturing services under one roof. This integrated approach streamlines your supply chain and simplifies the journey from concept to a market-ready product.

Engineering Expertise You Can Count On

Our experienced engineering team acts as a dedicated extension of your own. We excel at solving complex manufacturing challenges and collaborate closely with you to optimize your designs for quality, cost-effectiveness, and manufacturability.

Flexible Production Volumes to Match Your Needs

Whether you require a single prototype or a high-volume production run, our manufacturing capabilities are designed to scale with your demands. We support your product’s entire lifecycle, from initial launch to full-scale production.

Rapid Turnaround for a Faster Time-to-Market

In today’s fast-paced market, speed is a crucial advantage. We deliver fast, transparent quotes and pride ourselves on our rapid turnaround times, helping you get your innovative products to market sooner.

3D Printing Services

Instant Price