Understanding ESD-Safe Materials in 3D Printing: Why Static Control Matters

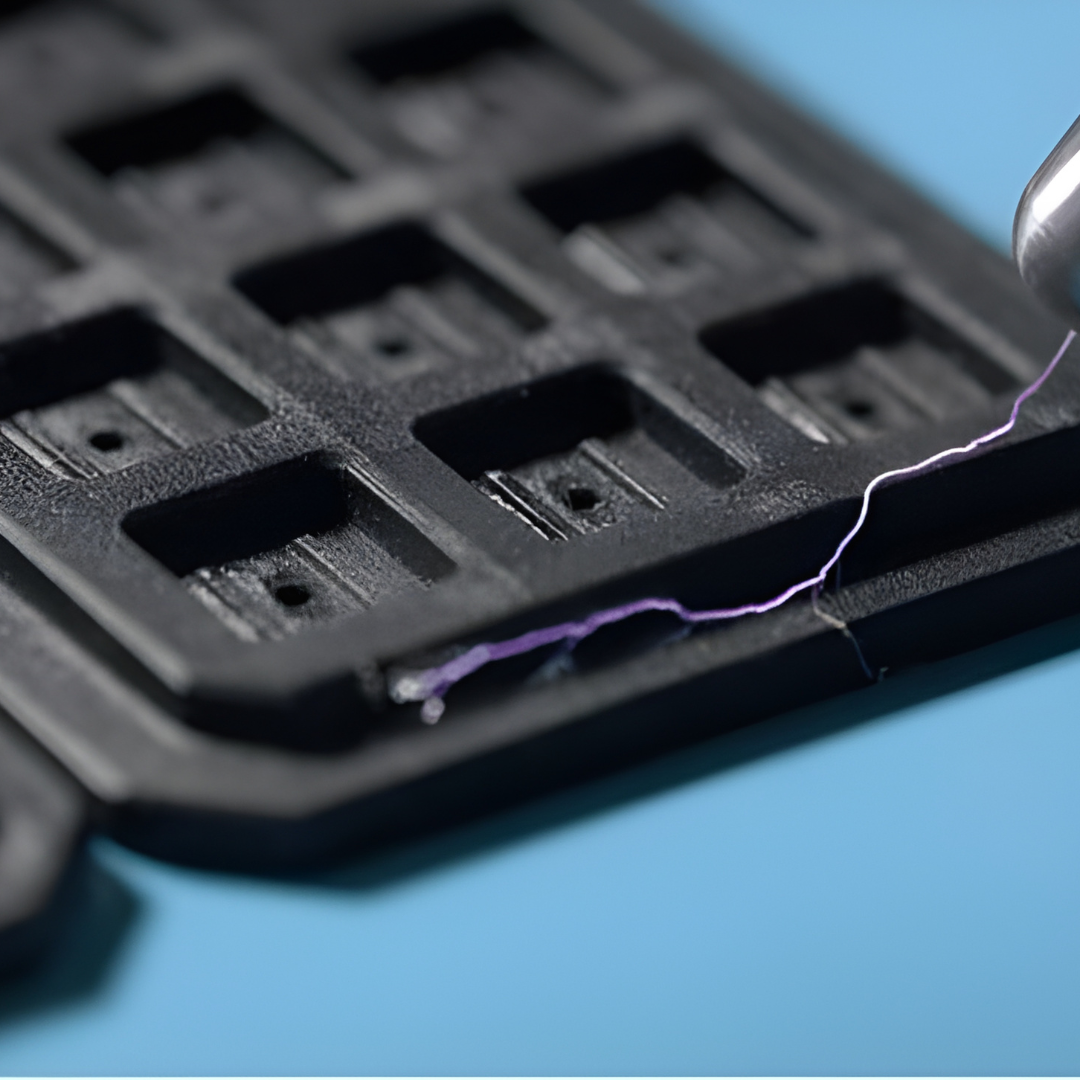

Most of us have experienced a mild static shock at some point. You walk across a carpeted floor on a dry day, reach for a metal doorknob, and ZAP!—a tiny jolt that you can feel and even hear. In everyday life, this is nothing more than an annoyance.

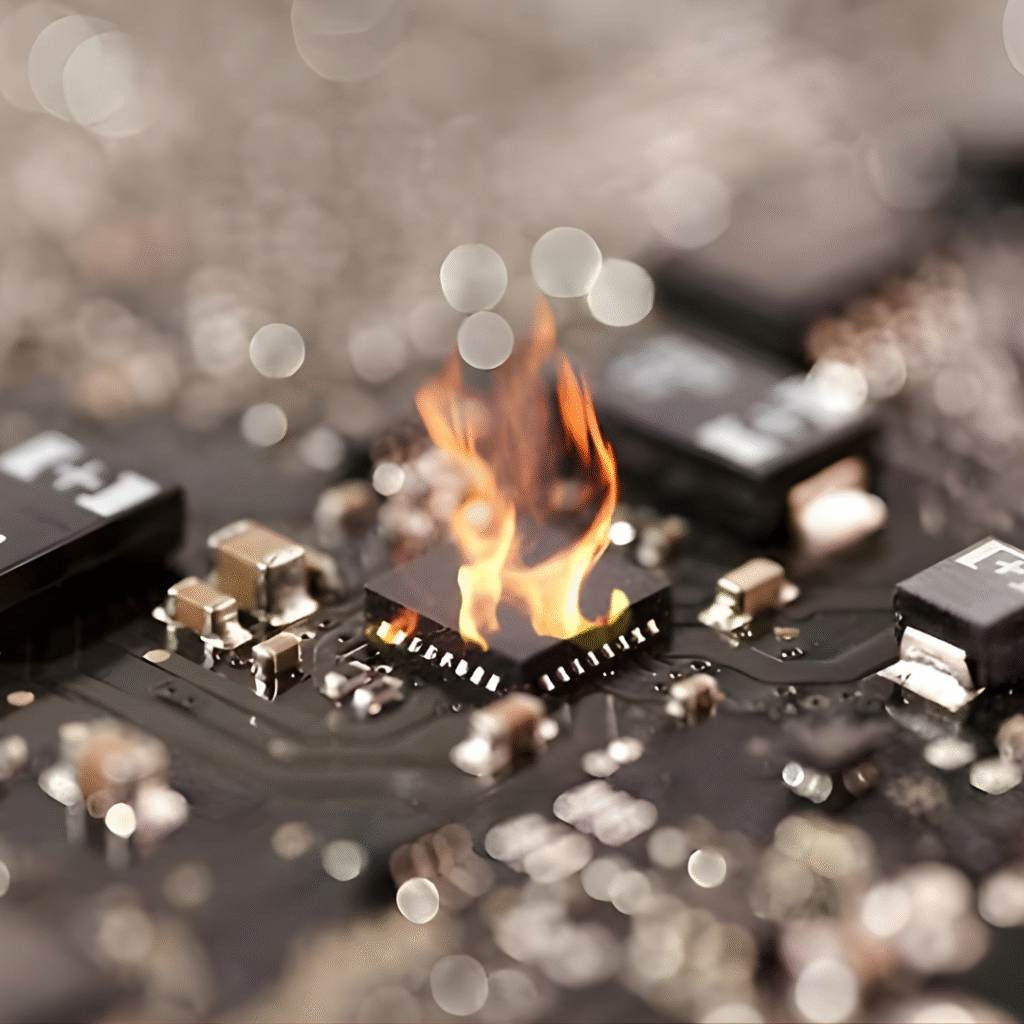

But in industrial environments, that very same phenomenon can lead to catastrophic consequences. A single electrostatic spark inside an electrical control box, fuel storage area, or chemical plant can ignite vapors or dust, triggering massive explosions or fires that burn for days. Even in less extreme settings, uncontrolled static discharge can silently destroy sensitive electronics long before anyone realizes something has gone wrong.

As 3D printing becomes more widely adopted in manufacturing, the availability of ESD-safe (electrostatic dissipative) materials is giving engineers new ways to improve product safety and reliability—especially in electronics, aerospace, and hazardous-environment applications.

Why ESD Control Is Essential

Static electricity is more than a nuisance—it is a real threat in many industries.

Electrostatic discharge can:

Damage microchips, sensors, and circuit boards

Interrupt manufacturing processes

Cause early component failure

Ignite flammable dusts, vapors, or gases

Compromise the reliability of devices during assembly or long-term use

In sectors such as semiconductors, automotive electronics, aerospace, medical devices, robotics, and industrial automation, static control is not optional—it’s a critical part of product design and facility safety.

This is where ESD-safe materials come into play.

What Makes ESD Materials Different?

To understand the value of ESD materials, it helps to compare them to standard insulators and conductors:

Insulators—like typical plastics—hold onto electrical charge, allowing static buildup.

Conductors—like metals—let electricity flow freely, which can cause sudden discharge.

ESD materials sit between these categories. They slowly dissipate charges in a controlled manner, preventing any sudden, dangerous sparks.

Electrostatic dissipative (ESD) materials used in 3D printing are engineered with special additives, such as carbon fibers, carbon nanotubes, or conductive polymers, to achieve specific resistance ranges that comply with industry standards.

This balanced electrical behavior ensures:

No rapid discharge

No dangerous charge buildup

Protection for sensitive electronic components

Safer operation in explosive or volatile environments

Applications Where ESD-Safe 3D Printing Matters

Because static can cause latent or immediate failure, ESD-safe parts are essential in many sectors:

Electronics manufacturing & assembly — jigs, trays, robotic end-effectors

Semiconductor fabrication — tool housings, wafer handling components

Aerospace — sensor mounts, enclosures

Automotive electronics — diagnostic fixtures, wiring housings

Explosive handling industries — fuel systems, mining, chemical facilities

Cleanroom environments — custom tools and fixtures

With 3D printing, manufacturers can create custom ESD-safe parts on demand, reducing lead times and eliminating the need for expensive molded components.

ESD-Safe 3D Printing Materials Available Today

Modern 3D printing offers several material options engineered specifically for electrostatic dissipation. Two commonly used examples include:

ABS-ESD

Strong and durable

Good impact resistance

Suitable for fixtures, enclosures, and tooling

Dissipative properties make it ideal for electronics handling environments

PETG-ESD

Excellent chemical and moisture resistance

Easy to print with high dimensional stability

Great for conveyors, trays, and cleanroom components

More temperature-stable than standard PLA or ABS

These materials allow manufacturers to produce parts that are mechanically strong, custom-shaped, and ESD compliant, enabling safer workflows and more reliable devices.

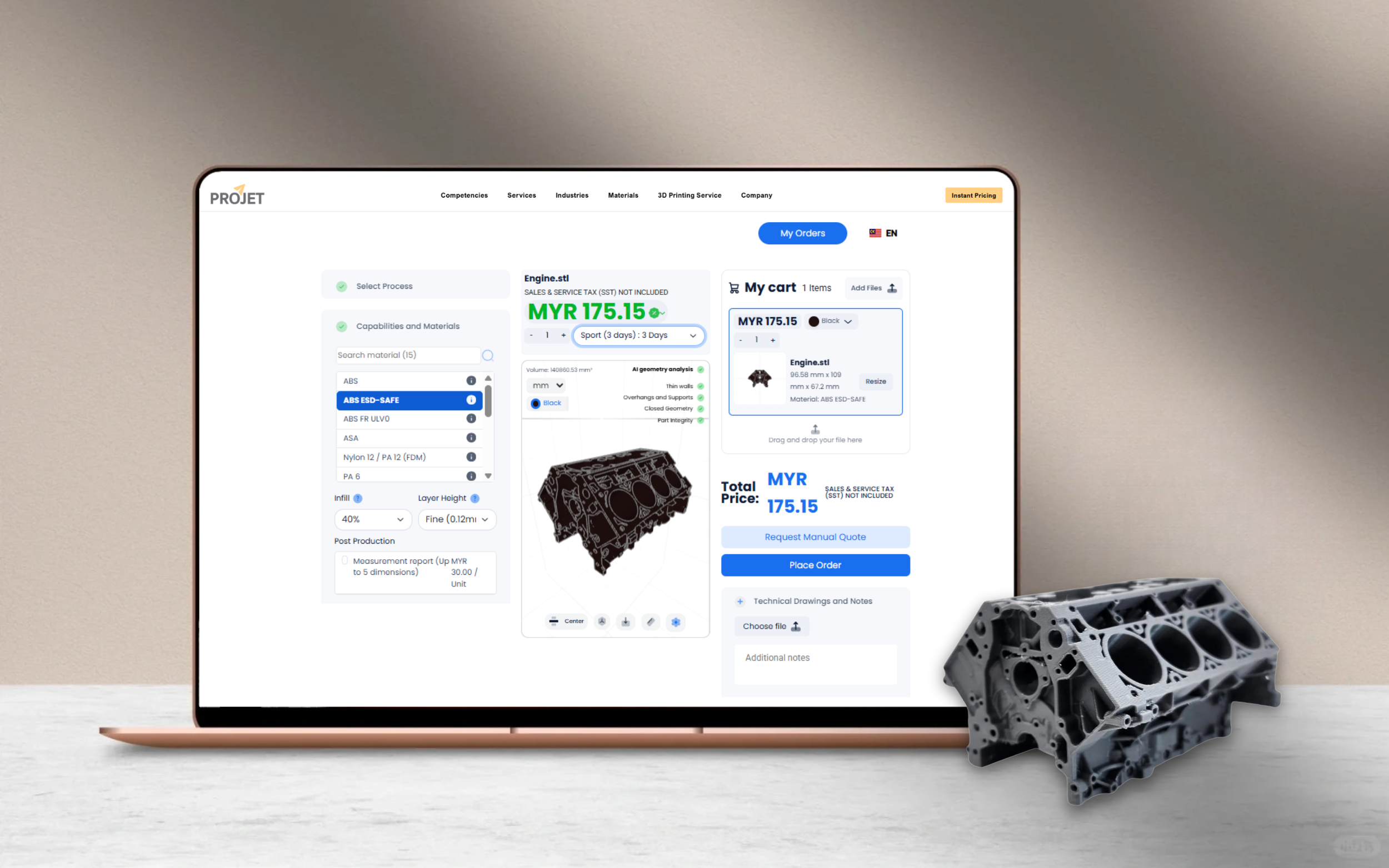

3D Printing Service Malaysia , 3D Printing service Singapore , 3D Printing service KL , 3D Printing service Selangor, 3D Scanning Malaysia

Why Choose Projet as Your Manufacturing Partner

Projet delivers fast, reliable, and high-quality manufacturing solutions for every stage of your product development— from prototype to production. With advanced 3D printing, CNC machining, vacuum casting, and injection molding, we offer the capabilities and expertise to bring your ideas to life.

✔ Fast Turnarounds – Rapid prototypes and production parts delivered on time

✔ High Precision & Quality – Industrial-grade machines and strict QC for consistent results

✔ Wide Material Options – Plastics, metals, elastomers, and engineering-grade materials

✔ Expert Engineering Support – DFM guidance and technical advice at every step

✔ Flexible Production – From one-off prototypes to low-volume batches

Projet is the partner you can rely on for smarter, faster, and more efficient manufacturing.

3D Printing Services

Instant Price