Threading in 3D printing involves embedding metal threaded inserts into plastic parts for durable and strong screw connections, achieved through heat-set or press-fit methods. Heat-set inserts are melted into undersized holes using a heated tool like a soldering iron, while press-fit inserts are forced in using pressure. These methods produce more reliable threads than directly printed ones, which can wear or shear easily.

Adding Threaded Features to CAD Models for 3D Printing

Engineers often wonder about the best way to add threaded features to their CAD models for 3D-printed parts. It’s an important question—especially as additive manufacturing is increasingly used for both prototyping and end-use production.

Threads can be difficult to print due to geometry and material limitations. For instance, threads with tapered edges can lose definition when they become thinner than the minimum feature size of the chosen material and technology. In some cases, they may not print at all. In others, the minor diameter becomes too large, leading to poor engagement. Technologies like Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS) can also leave a rough surface finish, which can interfere with thread functionality.

In short, as-printed threads—those created directly during the print—will vary in quality depending on the technology, material, and thread size. If you need fully functional threads, Projet recommends post-print threading methods for reliable results.

Adding Threads to Plastic 3D-Printed Parts

For plastic parts, Projet offers hand-tapping post-build and threaded inserts. If you plan to add threads after printing, make sure the threads or inserts are removed from your CAD model before upload.

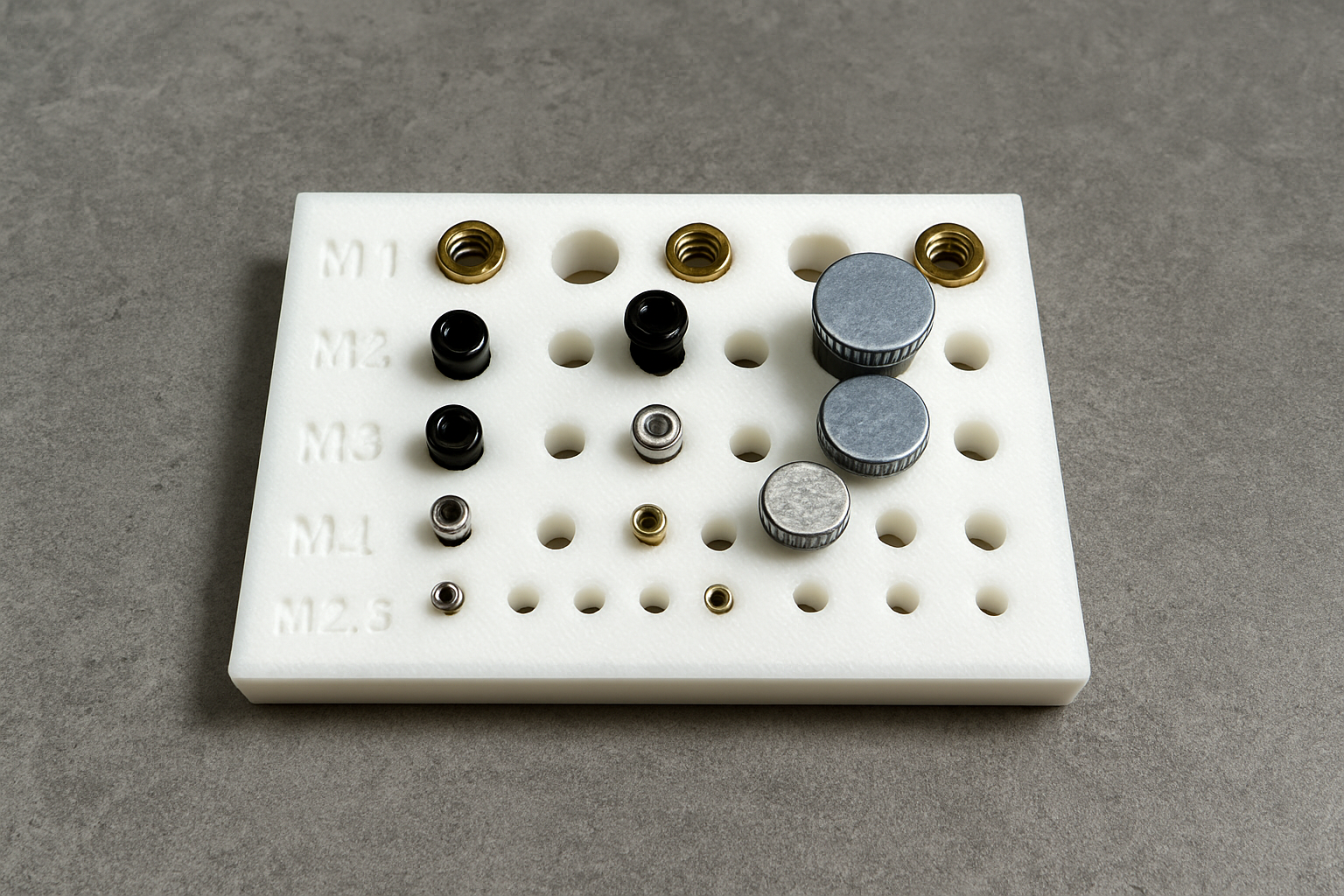

Taps and Inserts

Plastic parts can be hand-tapped after printing, but for stronger and more durable threads, threaded inserts are preferred. Projet provides taps and inserts for a wide range of standard and metric thread sizes.

For SLA (Stereolithography) parts, screw-to-expand inserts held in place with epoxy are typically used because SLA materials are sensitive to heat. For SLS and Multi Jet Fusion (MJF) parts, tapered heat-set inserts made of brass can be used. These are heated with a soldering iron and pressed into the part, melting the surrounding plastic slightly so it grips the insert tightly when cooled.

Available Tap Sizes

| Tap Sizes for SLS & MJF | Tap Sizes for SLA |

|---|---|

| Standard | Metric |

| 2-56 | M2 × 0.4 |

| 4-40 | M2.5 × 0.45 |

| 6-32 | M3 × 0.5 |

| 8-32 | M3.5 × 0.6 |

| 10-24 | M4 × 0.7 |

| 10-32 | M5 × 0.8 |

| 1/8-27 | M6 × 1.0 |

| 1/4-20 | M8 × 1.0 |

| 1/4-28 | M8 × 1.25 |

| 5/16-18 | M10 × 1.0 |

Available Insert Sizes

| Inserts for SLS & MJF | Inserts for SLA |

|---|---|

| Standard | Metric |

| 0-80 | M1.6 x 0.35 |

| 2-56 | M2 x 0.4 |

| 4-40 | M2.5 x 0.45 |

| 6-32 | M3 x 0.5 |

| 8-32 | M4 x 0.7 |

| 10-24 | M5 x 0.8 |

| 10-32 | M6 x 1.0 |

| 1/4-20 | M8 x 1.25 |

As-Printed Threads (Plastic)

While not recommended, as-printed threads can sometimes work if you respect minimum feature sizes. The larger the thread, the better the result. Keep in mind that smaller threads or tapered edges may not form correctly.

Adding Threads to Metal 3D-Printed Parts

For metal parts, Projet offers chasing and post-machining (tapping) of threads.

Chasing Threads

Chasing involves printing the threads into the model and then cleaning or refining them with a hand tap after printing. This method works well for prototypes and non-critical applications, as it’s faster and more cost-effective than full machining. However, surface roughness from DMLS may limit functionality.

Keep in mind that chased threads might have minor alignment or accuracy issues, so if precision is critical, Projet recommends machining threads post-build for tight tolerances and perfect alignment.

Tapping Threads

For the cleanest, most accurate threads—internal or external—tapping after printing is the best approach. Remove any thread geometry from your CAD model before submitting. Projet’s in-house machine shop can post-machine or thread-mill any required threads, with virtually no size limitation.

As-Printed Threads (Metal)

As-printed threads in metal parts rarely perform well due to material shrinkage and rough surface finishes. Some threads also require support structures between teeth if they form overhangs greater than 0.02 in. (0.5 mm).

Design Considerations

When designing for threading or inserts:

Ensure holes are properly sized and accessible for the tap or insert.

For inserts, leave enough wall thickness around the hole to maintain part strength.

For heat-set inserts, allow adequate clearance (around 0.25 in. or 6.35 mm) from surrounding features to avoid unintentional melting during installation.

Projet’s team reviews every design and ensures your holes are correctly sized and positioned before printing.

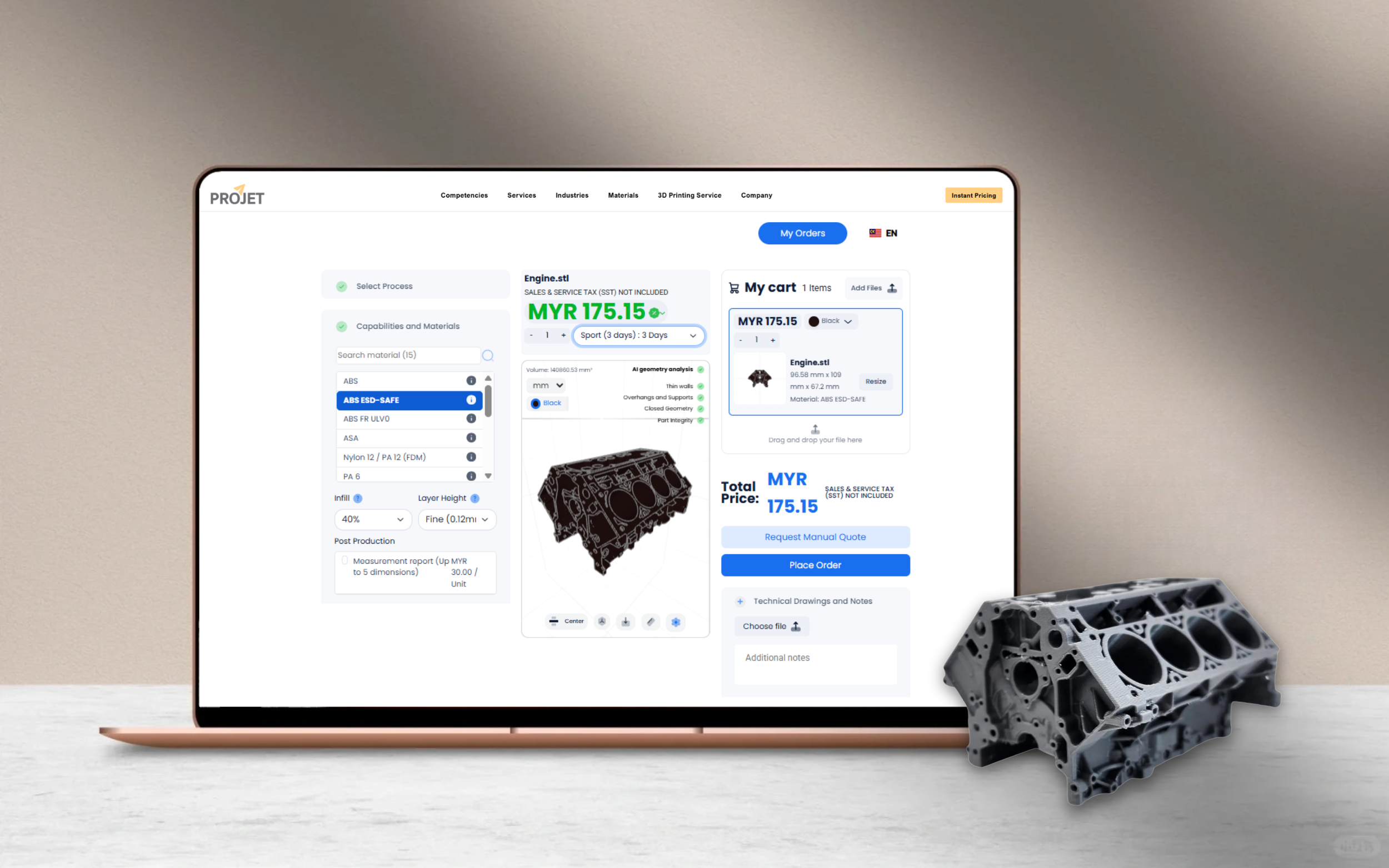

How to Request Threading from Projet

For plastic parts, threading falls under Projet’s Standard Finishing option.

In the Special Instructions, specify which holes require threads or inserts.

Attach an annotated image or drawing showing thread locations and sizes.

If threads are through-holes, indicate the tapping direction.

For metal parts, select Custom Finishing during quoting and include thread details in the Special Instructions or attach a drawing. Projet accepts STEP (.STP) or SolidWorks files for machining operations.

Special Request Inserts and Custom Hardware

If your project requires something unique—such as stainless steel inserts, compression limiters, or dowel pins—Projet can often accommodate custom hardware. Simply include the request with your CAD submission. Availability may vary by part material and design.

Projet’s applications engineers are also available to provide design guidance, cost analysis, and lead-time optimization to help you choose the best threading method for your project.

Why Projet is Your Manufacturing Partner

Choosing the right manufacturing partner ensures your parts meet performance and production needs. Projet stands out because:

End-to-end additive expertise – From design support to post-processing, Projet handles every stage of production.

Wide material and process range – SLS, MJF, DMLS, SLA, and FDM—Projet matches the best method to your design.

Precision and reliability – Advanced machining and inspection ensure parts meet your exact specifications.

Scalable production – From single prototypes to low-volume manufacturing, Projet grows with your needs.

Collaborative engineering – Our team partners with yours to find the right balance of performance, cost, and lead time.

At Projet, we’re not just printing parts—we’re building partnerships that help engineers and designers bring ideas to life faster, stronger, and smarter.

3D Printing Services

Instant Price