What is Bridge Production

Transitioning from prototyping to full-scale production is a major milestone for any company. It requires significant financial and operational commitments, along with readiness to bring a product to market. Bridge production, also known as bridge manufacturing, is a critical stage in the product development cycle that lets you validate parts before moving into large-scale production.

Bridge production also proves invaluable during supply chain disruptions. In such cases, thoughtful planning with a bridge manufacturing strategy ensures continuity while minimizing risks.

Benefits of Bridge Production

Think of it like a software analogy: if prototyping represents an “alpha” or “beta” version of your product, bridge production delivers a near-final iteration.

These pre-production parts are close to market-ready but may still require small refinements. They provide valuable insights when tested with internal teams or even early customers. Once final issues are resolved, transitioning to mass production becomes smoother—especially when working with the same manufacturer.

Bridge production is also highly useful in transitional phases between product versions or when demand is uncertain. It allows you to order the exact number of parts needed, avoiding excess inventory and reducing costs. As just-in-time delivery becomes more critical in modern business, bridge production helps lower risk and ensures you can fulfill demand on schedule.

Why Bridge Production Matters

Bridge production gives you:

Flexibility – Order the exact number of parts you need, when you need them.

Speed – Get to market faster without waiting for full production tooling.

Reduced Risk – Test, refine, and validate designs before investing in high-volume molds.

Supply Security – Keep production rolling during disruptions or unexpected demand spikes.

In short, it saves you time, money, and headaches while ensuring your product is market-ready.

Bridge Production Capabilities

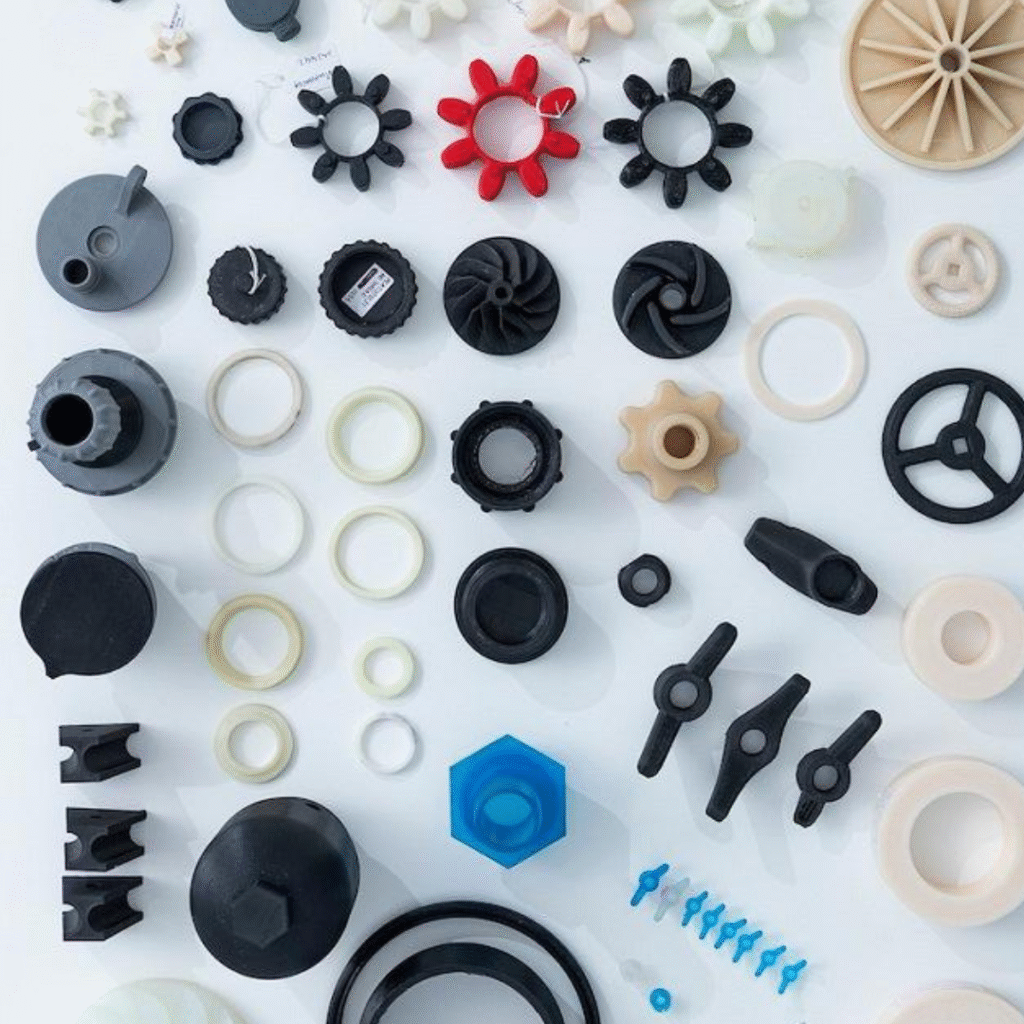

Bridge production can be applied across several manufacturing methods. Here are some common scenarios where it provides clear advantages:

3D Printing

3D printing is a natural fit for bridge production. Its flexibility allows you to:

Produce parts quickly on tight timelines.

Update CAD designs easily and reprint iterations without costly tooling changes.

Bridge demand spikes or tool unavailability.

Create plastic or metal parts for pre-production validation before investing in injection molds.

CNC Machining

When emergencies arise, CNC machining often serves as a fast, reliable bridge production option.

A company once faced a major crisis when their magnesium die-casting supplier had a fire. Quick-turn CNC machining kept their production moving until they secured a long-term solution.

This flexibility ensures development timelines and revenue targets remain intact, even in challenging situations.

Sheet Metal Fabrication

Imagine developing a new consumer device that needs to debut at upcoming trade shows. The electronics are ready, but the metal casing isn’t finalized. Bridge production allows you to fabricate a limited run of sheet metal housings for demonstrations—quickly, cost-effectively, and without the risks of large-scale production.

This approach ensures your product makes an impact while keeping options open for design adjustments before final production.

Making Bridge Production Work for You

Working with a single manufacturing partner across your product lifecycle—from prototyping to bridge production to mass manufacturing—delivers consistency and efficiency. Knowledge gained at each stage carries forward, reducing risks and ensuring smoother transitions.

Manufacturing partners like Projet, with broad capabilities across 3D printing, CNC machining, and sheet metal fabrication, can support you at every stage. This continuity not only minimizes disruptions but also provides a reliable fallback when supply chain challenges arise.

Bridge production should be a built-in step of every product development plan. It reduces risks, cuts costs, and enables businesses to adapt quickly to both predictable and unexpected challenges.

Whether you’re preparing for launch, bridging a supply chain disruption, or managing end-of-life production, Projet’s bridge manufacturing solutions can help you move forward with confidence.

How Projet Helps

At Projet, we offer a full range of bridge production solutions:

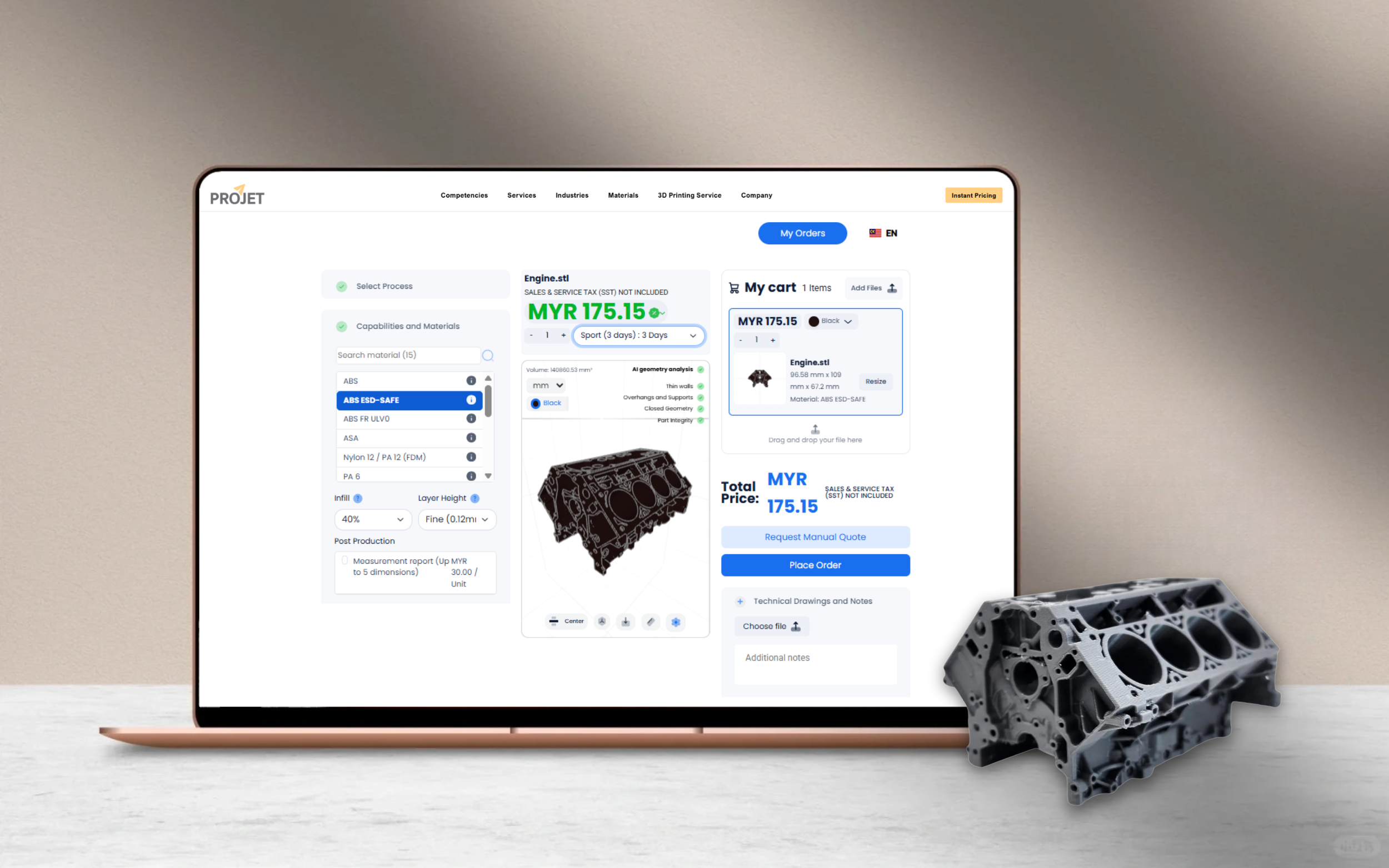

3D Printing – Perfect for quick-turn parts, design tweaks, or small runs without tooling costs.

CNC Machining – Reliable for emergencies or short-term production needs.

- Sheet Metal Fabrication – Ideal for low-volume runs of enclosures, brackets, or housings.

Whether you’re preparing for launch, managing unpredictable demand, or phasing out a product, bridge production keeps you moving forward with confidence.

3D Printing Services

Instant Price