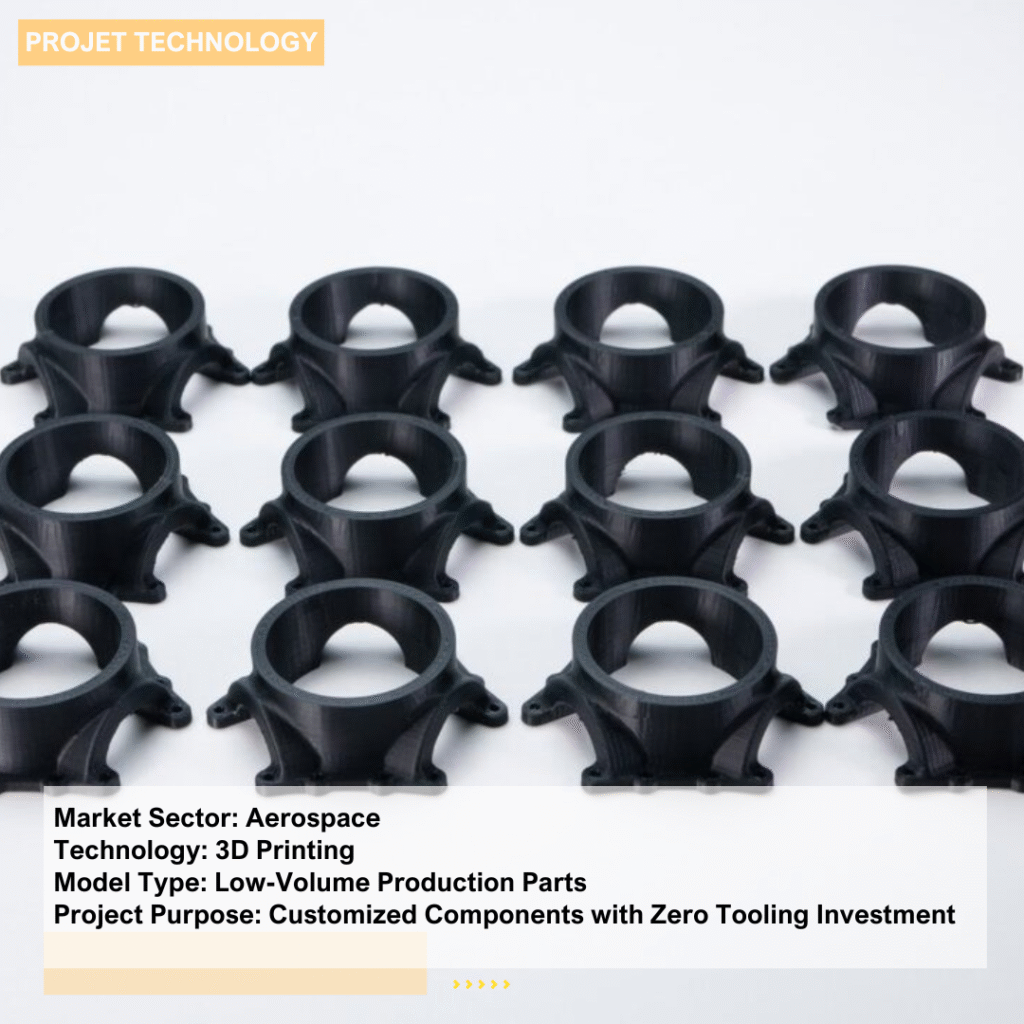

Discover how we helped an aerospace project avoid costly delays using rapid 3D printing—no tooling required. Learn the cost & time savings!

That Monday Morning Call:

“We need 3,000 pieces of aerospace components parts in 4 weeks time and no budget for tooling.”

That was Alisa, a purchasing lead at an aerospace firm, facing a nightmare scenario:

- Aircraft certification testing was stuck waiting for these components.

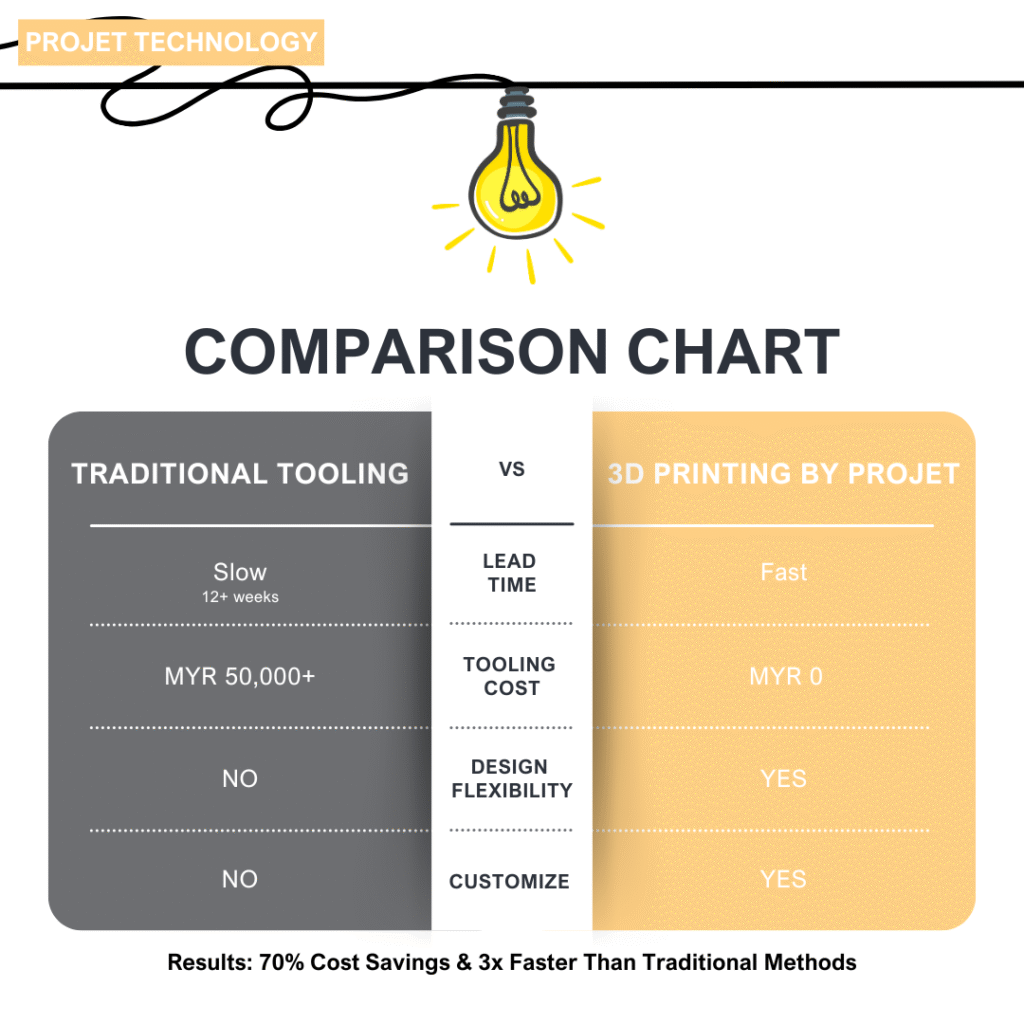

- Traditional suppliers quoted 12+ weeks (and six figures for tooling).

- CNC machining couldn’t meet the volume in time.

Her team was out of options until she found us — Projet.

72 Hour Turnaround That Saved the Project

We proposed a radical (yet proven) solution: skip tooling entirely and 3D print the batch. Here’s how it unfolded:

Day 1 – Emergency

- Alisa’s email hits our inbox with 2D drawings and STEP files

- Quick short meeting to understand the requirements

- Our engineers optimized the design for 3D printing by noon

Day 2 – Sample Submission

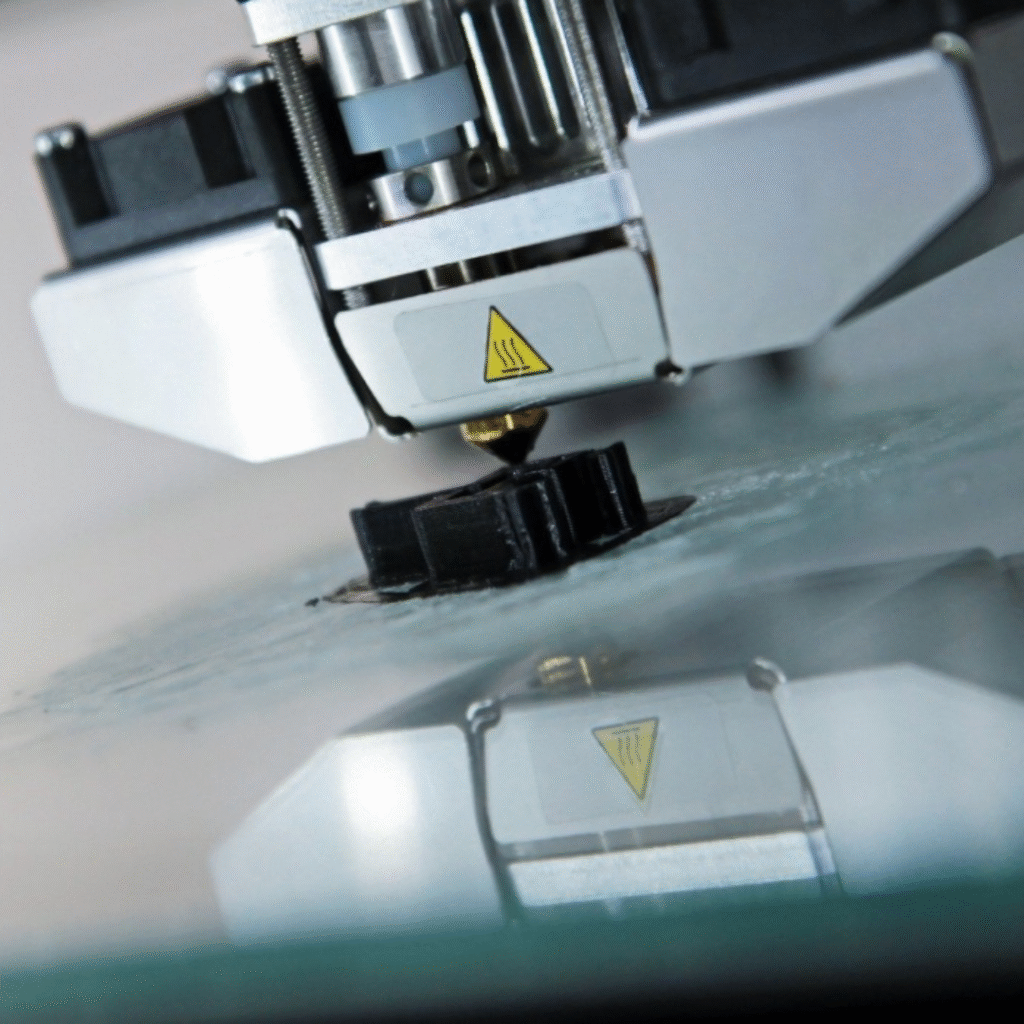

- Overnight print of our first sample begins

- First test part came off the printer—internal channels perfect.

- Courier speeds sample to Alisa’s Production for urgent testing

Day 3 – The Green Light

- “Approved! PO coming.” email arrives

- Full production launch – every printer mobilized

Day 30 – Delivery Day:

- 3,000 flight-ready components shipped on time

- Cost: MYR 2X,XXX (saving 70% vs traditional methods)

Why This Matters for Aerospace

✔ Tooling-Free Agility

No MYR 50K mold investment • No 12-week wait

✔ Volume When You Need It

From 50 to 3,000 units with just a file upload

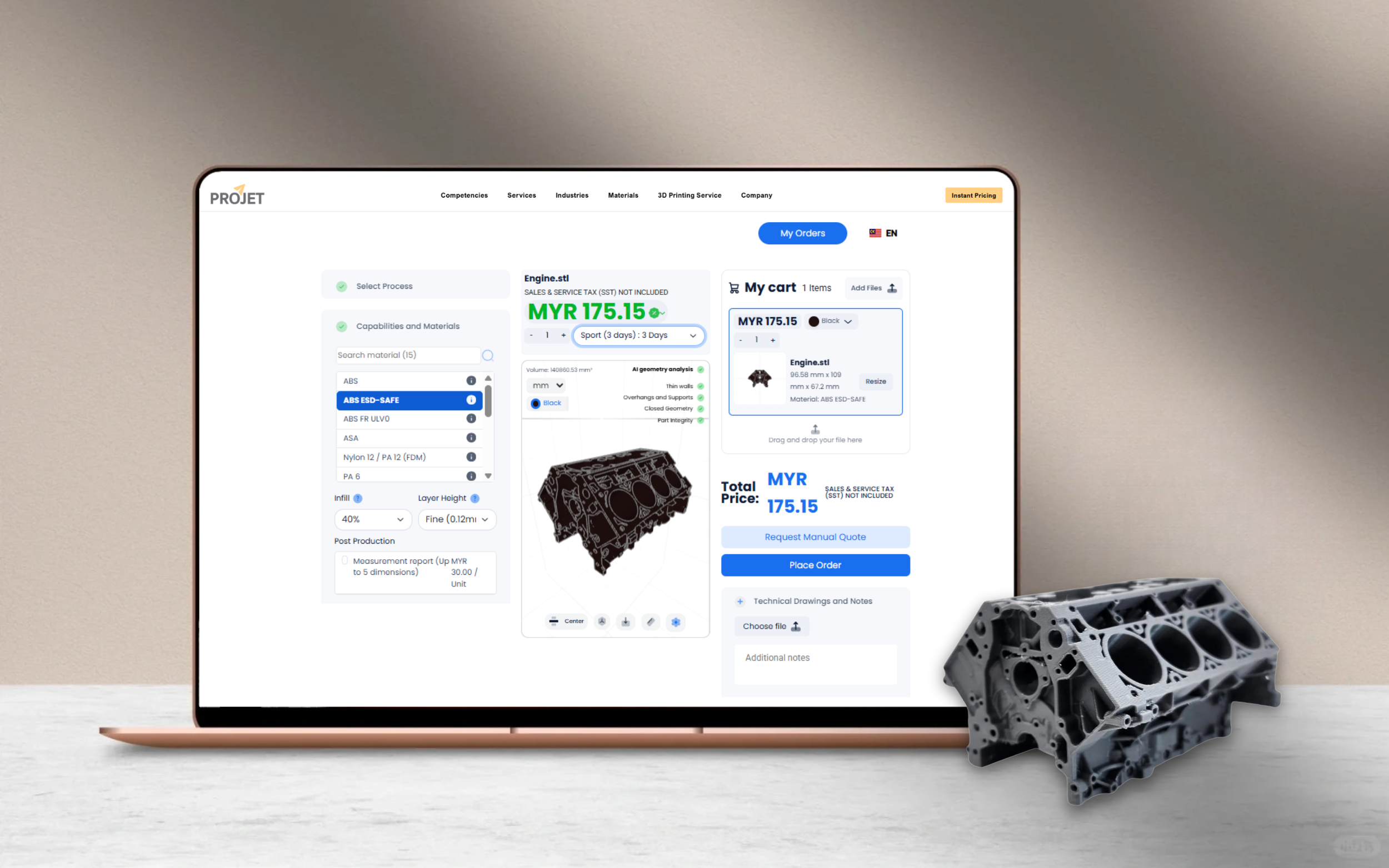

3D Printing Service Malaysia , 3D Printing service Singapore , 3D Printing service KL , 3D Printing service Selangor, 3D Scanning Malaysia

3D Printing Services

Instant Price