Market Sector: Automotive

Processes Used: CNC Machining

Model Type: Functional/Working Prototypes

Project Purpose: Rapid Product Development Prototype

Background

In the fast-paced automotive sector, engineers face immense pressure to validate designs quickly and cost-effectively. Delays in prototyping can derail development timelines, increase costs, and allow competitors to gain market advantage. Short lead times are critical to ensure designs are tested, iterated, and production-ready without compromising quality.

Customer Profile

Name: Mike

Role: Mechanical Engineer (Automotive Sector)

Challenge:

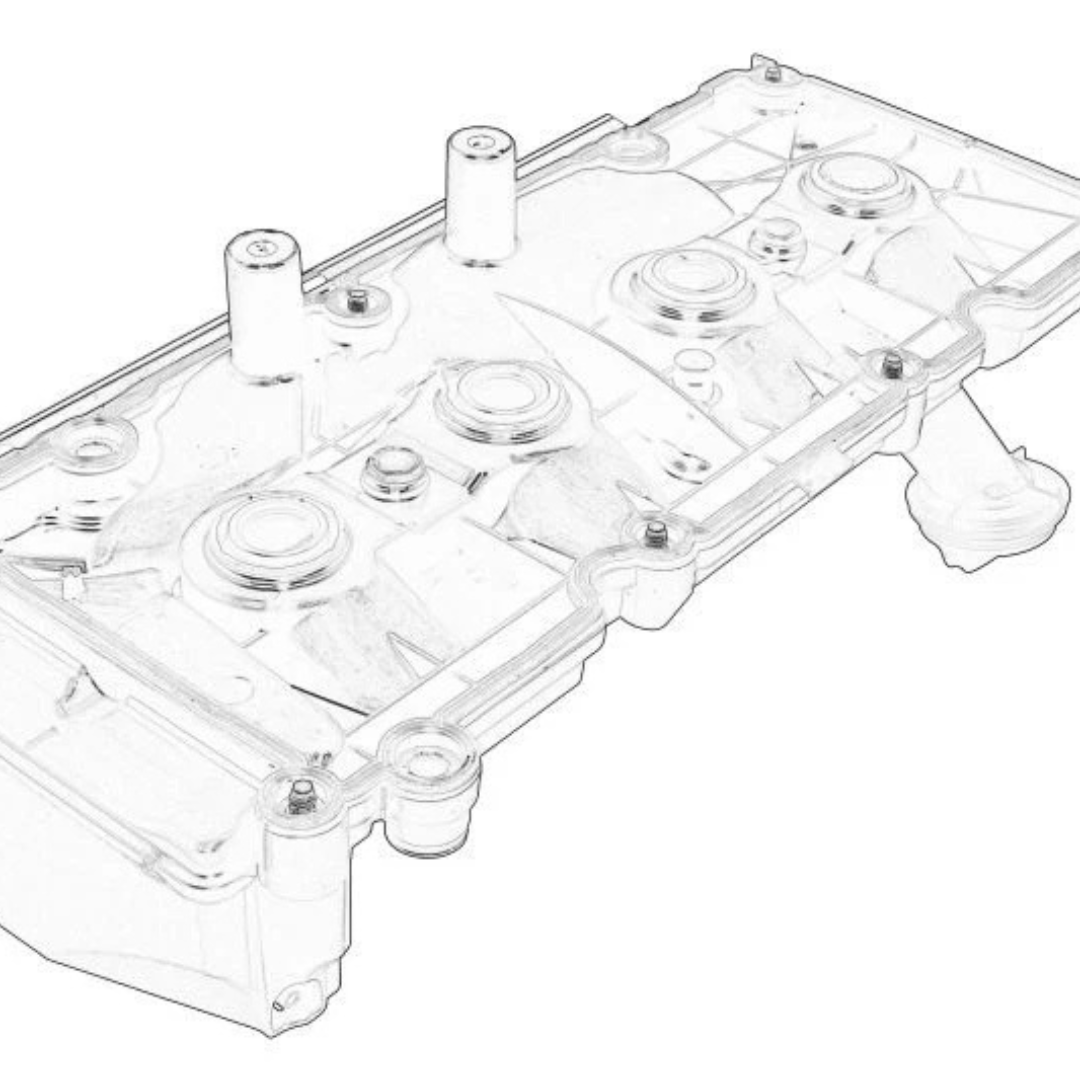

- Needed a high-precision, functional prototype for an automotive component to test its feasibility before committing to full-scale production

- Needed the prototype delivered in <2 week to meet an accelerated product development schedule.

Project Requirements

- Speed: Fast turnaround to meet tight development deadlines.

- Precision: High accuracy to ensure functional testing reliability.

- Material Options: Needed qualified materials that mimic final production-grade properties.

- Complex Geometries: Required fine feature resolution for intricate parts.

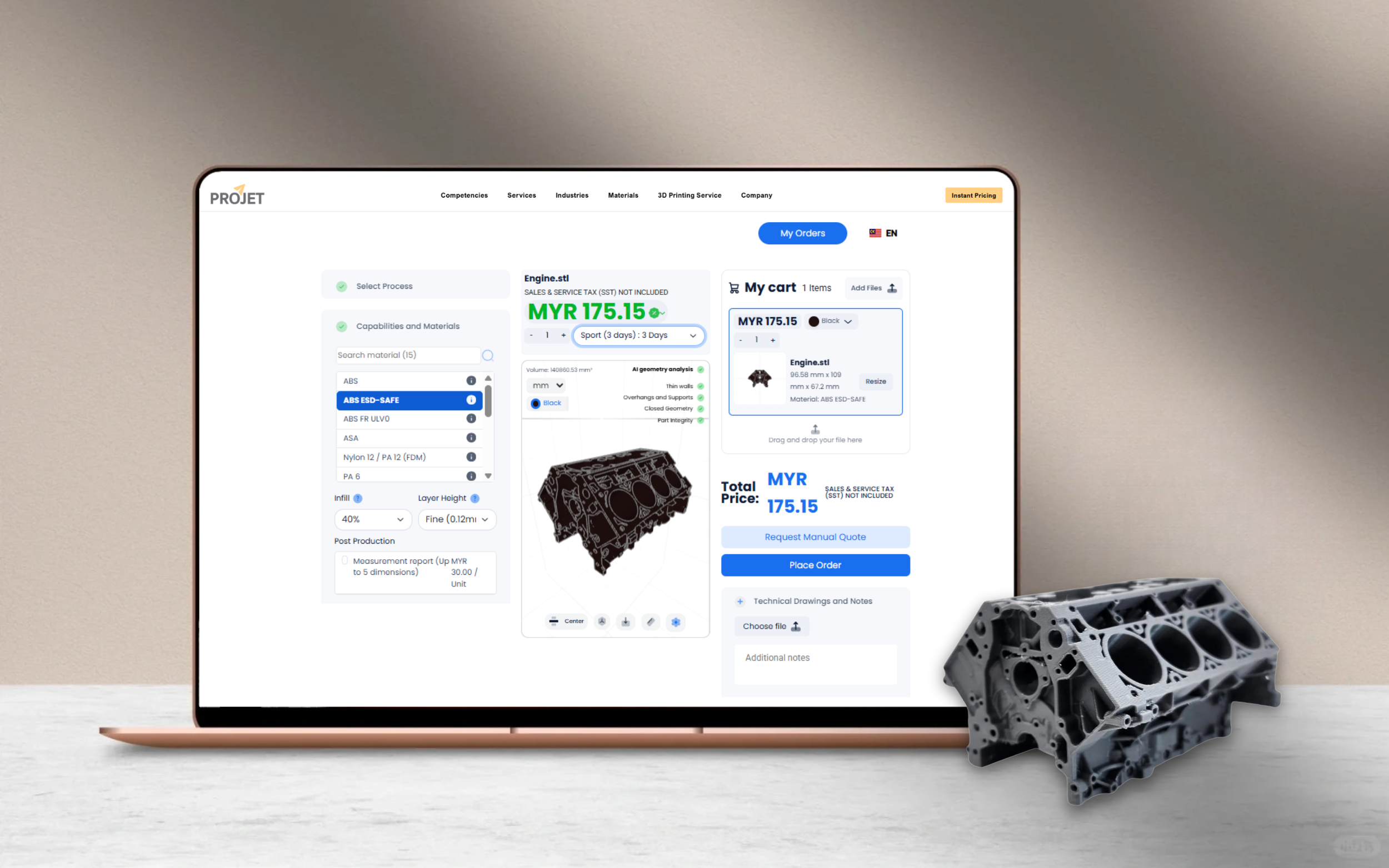

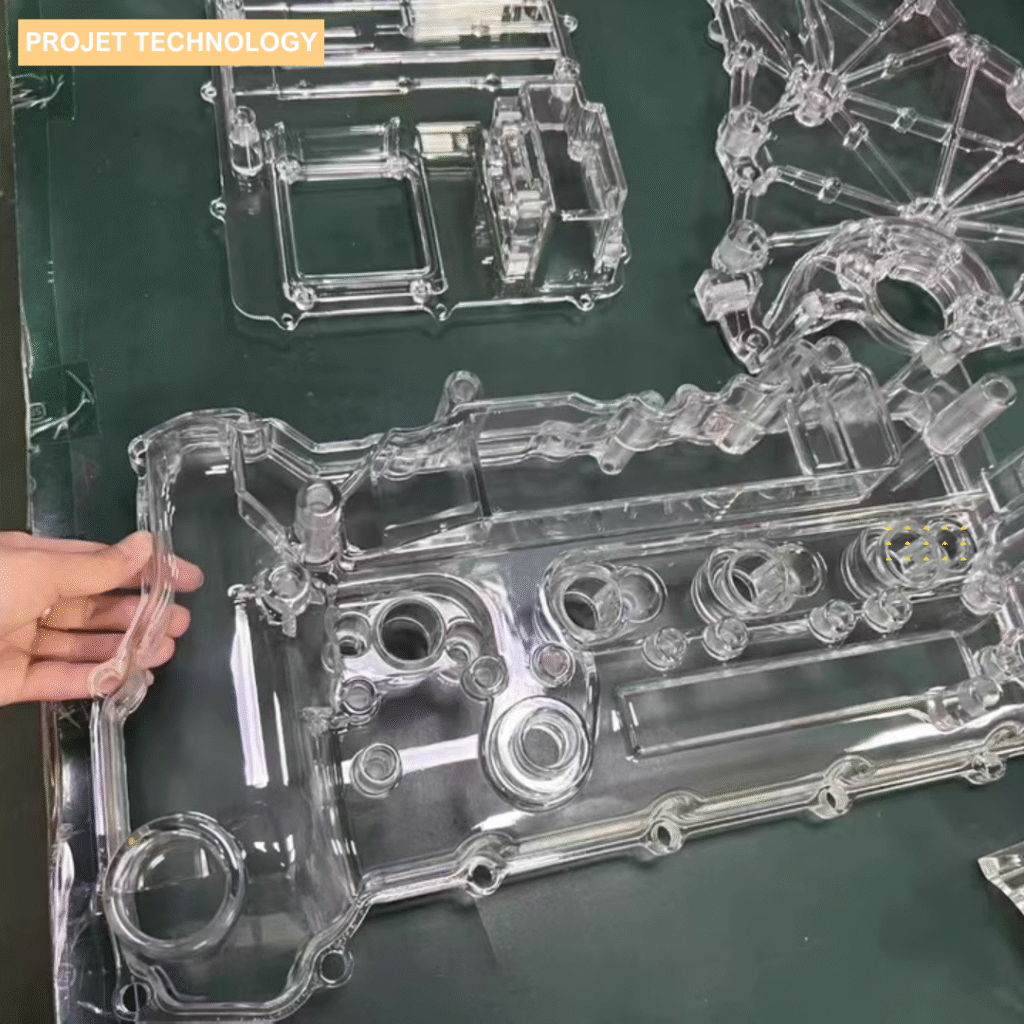

Solution: CNC Machining for Rapid Prototyping

Mike approached Projet for

- Quick Turnaround: Rapid production of machined parts without the need for tooling.

- High Precision: Tight tolerances for functional testing.

- Material Variety: Engineering-grade plastics for realistic performance.

- Scalability: Ability to produce single prototypes or low-volume pre-production parts.

Results & Benefits

- Accelerated Development: Mike received a working prototype in days instead of months.

- Functional Validation: The part was tested under real-world conditions, confirming design integrity.

- Cost Savings: Early detection of design flaws prevented expensive revisions later.

- Manufacturing Feedback: Insights from CNC machining helped optimize the part for mass production.

By leveraging CNC machining for rapid prototyping, Mike successfully validated his automotive component before moving to production. Projet capabilities in speed, precision, and material options ensured a seamless transition from concept to functional prototype, reducing time-to-market and development risks.

3D Printing Service Malaysia , 3D Printing service Singapore , 3D Printing service KL , 3D Printing service Selangor, 3D Scanning Malaysia

3D Printing Services

Instant Price