Revolutionizing High-Mix Low-Volume (HMLV) Manufacturing with 3D Printing in Malaysia

In the ever-evolving world of manufacturing, businesses are increasingly adopting High-Mix Low-Volume (HMLV) production strategies to meet diverse customer demands while maintaining flexibility and cost-efficiency. Additionally, this approach enables companies to respond swiftly to market changes, reduce waste, and cut inventory costs. Nevertheless, implementing HMLV requires meticulous planning and investments in adaptable technologies.

By integrating automation and data analytics, manufacturers can streamline operations while enhancing product quality. As a result, HMLV not only supports customization but also boosts competitiveness in a dynamic market. At the forefront of this transformation is 3D printing, a technology that allows manufacturers to produce complex, customized parts without expensive tooling or long lead times.

In Malaysia, Projet is leading this innovation by offering cutting-edge 3D printing solutions tailored to HMLV manufacturing needs. Whether you’re in Kuala Lumpur, Penang, Johor Bahru, or elsewhere in Malaysia, Projet is your trusted partner for leveraging 3D printing to optimize HMLV production. Let’s delve into how 3D printing is revolutionizing HMLV manufacturing and how Projet can help you stay ahead.

What is High -Mix Low-Volume (HMLV)

HMLV manufacturing, which stands for the production of a wide variety of products in small quantities, is especially prevalent in industries like aerospace, automotive, healthcare, and consumer goods, where customization and rapid iteration are essential.

However, traditional manufacturing methods often fall short in meeting HMLV demands due to high setup costs, long lead times, and inefficiencies in small-batch production. This is precisely where 3D printing comes into play. By leveraging additive manufacturing, companies can eliminate the need for tooling, significantly reduce waste, and enable rapid design changes.

As a result, 3D printing emerges as the ideal solution for HMLV production, offering unparalleled flexibility and efficiency.

How 3D Printing Transforms HMLV Manufacturing

Cost-Effective Customization

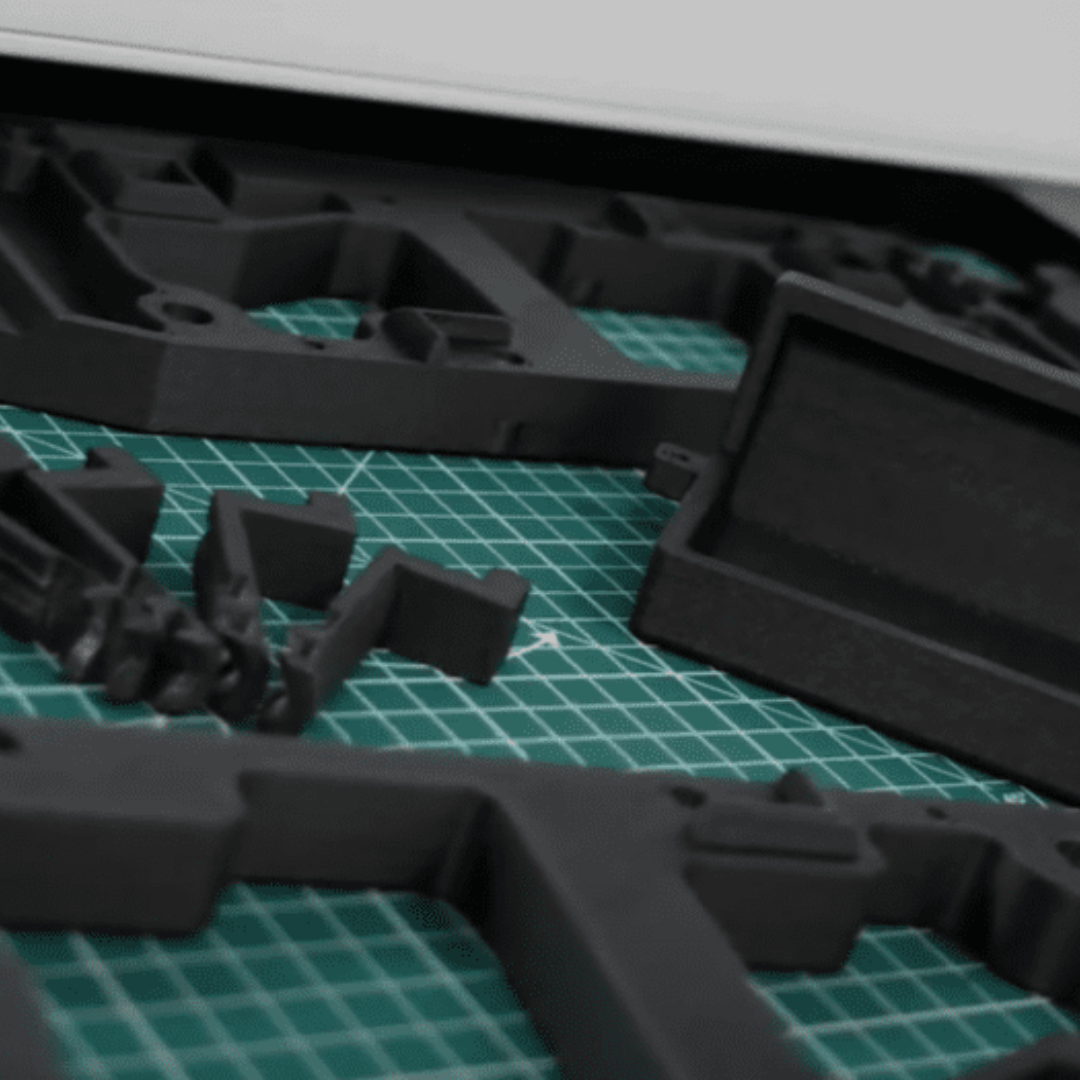

3D printing enables the production of highly customized parts without the need for expensive molds or tooling. This is especially beneficial for HMLV manufacturers who need to produce small batches of unique components.Rapid Prototyping and Iteration

With 3D printing, you can quickly prototype and test multiple design iterations, reducing time-to-market and ensuring optimal performance for your products.On-Demand Production

Additive manufacturing allows you to produce parts on demand, reducing inventory costs and minimizing waste. This is ideal for HMLV manufacturers who need to respond quickly to changing customer demands.Complex Geometries Made Simple

3D printing excels at producing complex, lightweight structures that are difficult or impossible to achieve with traditional manufacturing methods. This opens up new possibilities for innovation in product design.

Applications of 3D Printing in HMLV Manufacturing

Aerospace: Lightweight, high-strength components for aircraft and satellites.

Automotive: Custom jigs, fixtures, and end-use parts for vehicles.

Healthcare: Patient-specific implants, prosthetics, and surgical guides.

Consumer Goods: Customized products and small-batch production.

Industrial Equipment: Spare parts, tooling, and functional prototypes.

3D Printing in HMLV Manufacturing

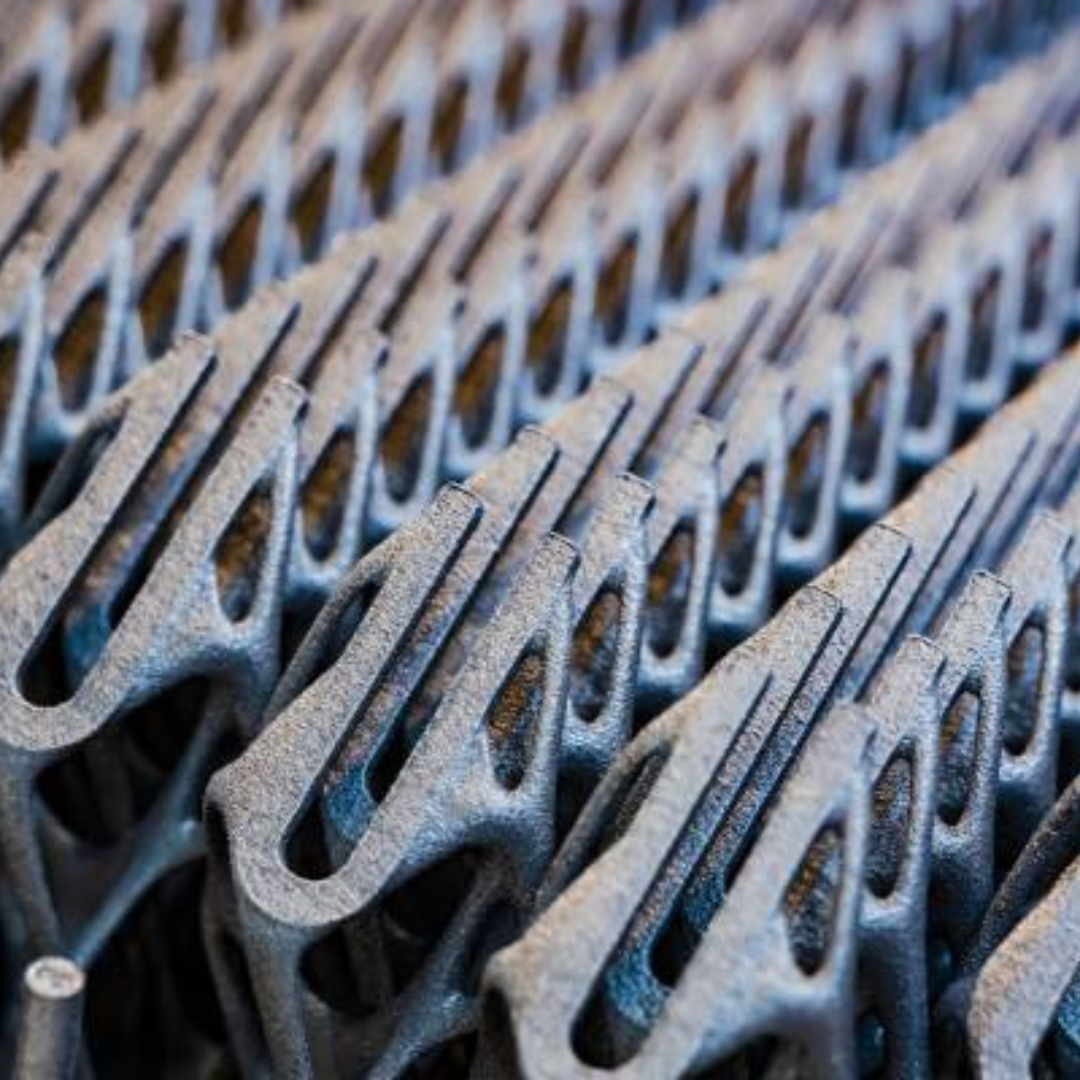

3D printing, or additive manufacturing, has emerged as a game-changer for HMLV production. By building parts layer by layer, 3D printing eliminates the need for tooling and enables rapid, cost-effective production of customized parts.

Advantages 3D Printing in HMLV Manufacturing

- No Tooling Required: 3D printing eliminates the need for expensive molds or tooling, making it ideal for small-batch production.

- Rapid Prototyping and Iteration: Design changes can be implemented quickly, reducing time-to-market.

- Cost-Effective Customization: Producing unique, customized parts is economically feasible with 3D printing.

- Complex Geometries: Additive manufacturing can create intricate, lightweight structures that are impossible with traditional methods.

- Reduced Waste: 3D printing is an additive process, meaning it uses only the material needed, minimizing waste.

3D Printing vs. Traditional Manufacturing: A Comparison for HMLV

| Aspect | 3D Printing | Traditional Manufacturing |

|---|---|---|

| Setup Costs | Low (no tooling required) | High (expensive molds and tooling) |

| Lead Times | Short (rapid production) | Long (tooling design and production) |

| Customization | High (ideal for unique parts) | Low (costly to customize) |

| Material Waste | Minimal (additive process) | Significant (subtractive process) |

| Complex Geometries | Excellent (can produce intricate designs) | Limited (difficult with traditional methods) |

| Surface Finish | May require post-processing | High-quality finish |

| Volume Suitability | Ideal for low-volume production | Better for high-volume production |

Why Choose Projet for HMLV Manufacturing in Malaysia or beyond?

Expert Collaboration for Optimal Results

At Projet, we work closely with you to understand your HMLV manufacturing needs. Our team helps you choose the best materials and optimize build orientation to ensure your parts are produced with precision and efficiency.Wide Range of Materials

Explore our 3D Printing Materials Guide to discover a variety of plastic and metal materials across different technologies. From durable ABS and nylon to high-performance metals like titanium and aluminum, we have the perfect material for your application.State-of-the-Art Technology

We leverage the latest in additive manufacturing technology to deliver high-quality, reliable parts that meet the demands of HMLV production.Nationwide Reach

No matter where you are in Malaysia—be it Kuala Lumpur, Penang, Johor Bahru, or beyond—Projet is your go-to partner for 3D printing services.

3D Printing Service Malaysia , 3D Printing service Singapore , 3D Printing service KL , 3D Printing service Selangor, 3D Scanning Malaysia

Transform Your HMLV Manufacturing with Projet

3D printing is revolutionizing the way manufacturers approach High-Mix Low-Volume production, offering unparalleled flexibility, cost-efficiency, and innovation. In Malaysia, Projet is your trusted partner for leveraging this transformative technology to stay competitive in today’s dynamic market.

Visit www.projet.my to learn more about our 3D printing services, explore our materials guide, and get started with your next project. For assistance, reach out to our applications engineers at enquiry@projettech.com or try our Online Instant Quote tool for immediate pricing feedback.