1-Stop Rapid Fabrication

Solution Provider Malaysia & Singapore

We specialize in urgency resolution, providing rapid and efficient solutions to critical problems under tight deadlines.

- Rapid prototyping

- Flexible on-demand service

- Online 3D printing service

- Consistent quality end-use part

Serving diverse customer base

Our competencies

We are a highly dependable mechanical powerhouse with an extensive array of additive manufacturing (3D Printing) & subtractive manufacturing capabilities. Catering from one-off prototyping to low-volume production, we offer solutions that span from basic to industrial, including cosmetic finishing manufacturing.

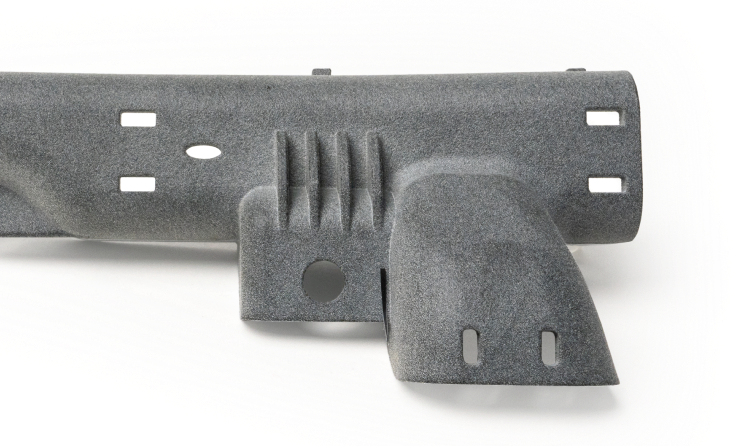

3D Printing

SLS,SLA,SLM,FDM,MJF,PµSL

- Tolerances accuracy ± 0.02 mm

- Tolerances accuracy ± 0.20 mm

- Class 1 surface finishing

- Engineering grade material

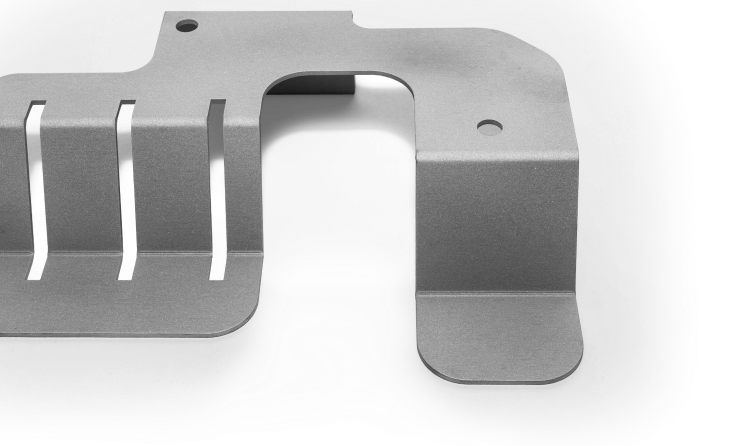

Laser Cutting

CO2 Laser

- Bending, welding

- Stainless steel, aluminium

- Thermoplastic, tapes & gaskets

- Cutting, boring, engraving, etching

Vacuum Casting

Urethane Casting

- Material flexibility

- High transparency

- Production-like parts

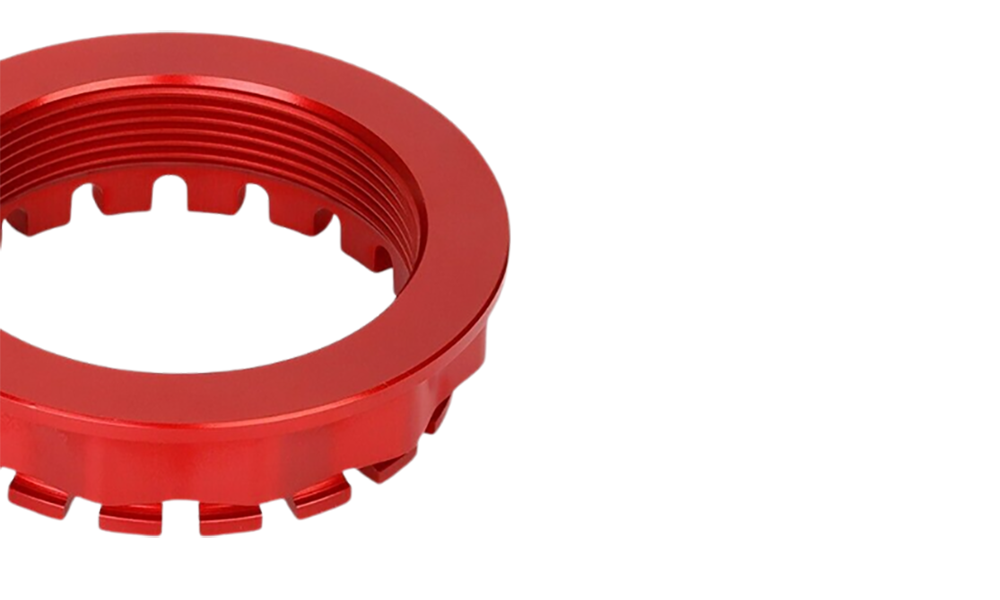

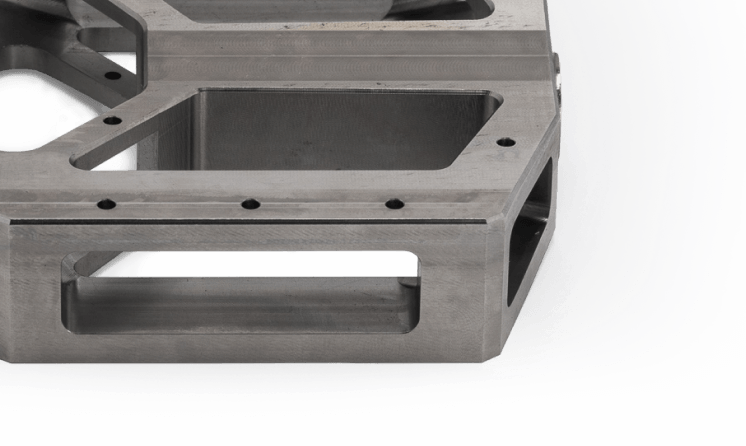

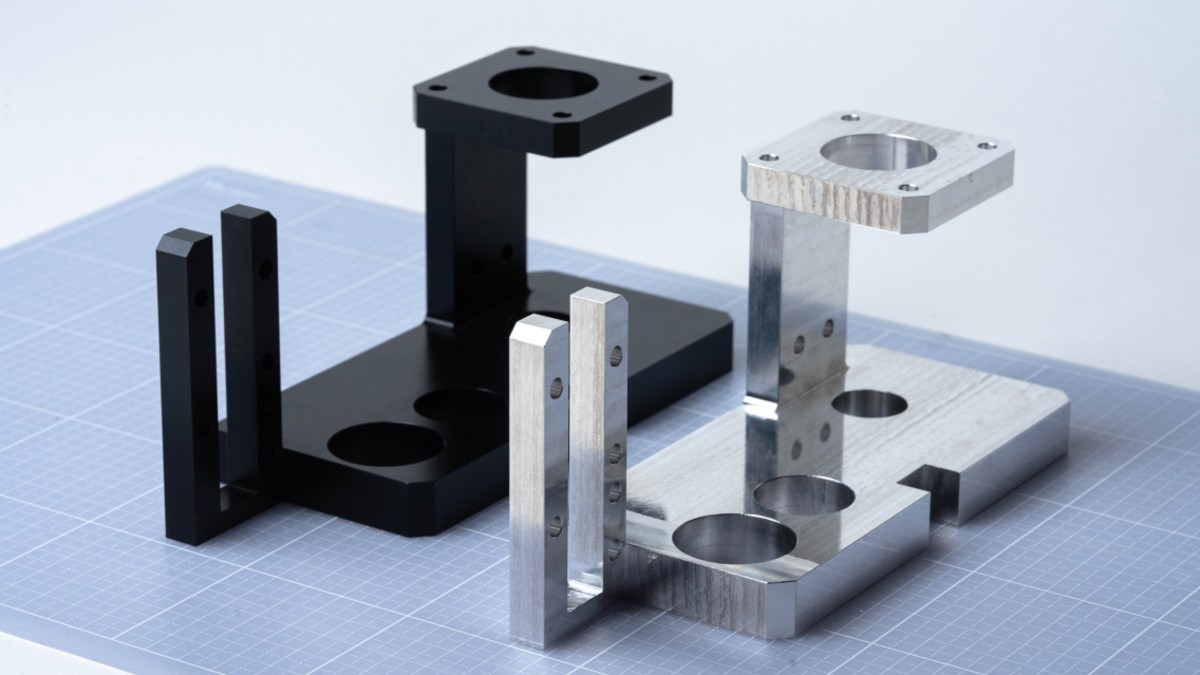

CNC Machining

Milling, Turning

- Tolerances down to ± 0.03 mm

- 3 & 5 axis

- Anodizing, powder coating

- Wide range of material

Rapid prototyping to volume production

Projet actively revolutionizing with technology – propelling entire industries forward by showcasing its impact in every stage, from rapid prototypes to crafting end-use parts that redefine efficiency.

This isn’t just a vision – it’s the reality we’re shaping. We’ve pioneered a groundbreaking solution that revolutionizes how parts are designed and prototyped. By leveraging the unique abilities, we’re able to speed up product development, offer cost-effective low-volume manufacturing with no minimum order quantity, and shore up manufacturing workflows.

Volume production

Time is money, and we’re saving you both. Think of us as production time machine. We’ll warp 3D printing volume orders from months to weeks, leaving our clients with more time to focus on what matters most.

- High-quality finish, meets market standards

- Durable and long-lasting materials specifications

- Low mix high volume/ high mix low volume

- Custom end-use parts/ mass customization

Ensure every order meets your desired specifications, consistently

Projet standard

ISO 9000:2015 certified, we have established rigorous processes to uphold the highest manufacturing standards for every custom part.

Quality control

All parts undergo dimensional checks using calibrated metrology equipment, visual inspection by high trained inspectors.

Quality assurance

Our quality management system helps improve the quality of our products and services and consistently meet our clients' expectations.

ISO 9000 Certified 3D Printing Service

Bring your ideas to life with fast, precise, and affordable 3D printing solutions with no minimum order.

We offer a wide range of additive manufacturing services – from FDM & SLA polymer parts to SLM metal parts, and high performance MJF & SLS printing.

Our precision applications are perfect for aerospace, automotive, medical, robotics, industrial, consumer electronics industries, and many more. We offer CoCs, material certifications, finishing certifications, inspection reports, and hardware certifications.

With more than 30 3D printers, we have unmatched capacity that reliably delivers parts within days. In addition to a broad material selection, we offer several post-processing options to improve cosmetics or enhance mechanical properties.

3D Printing Service Online for Custom Parts

On-demand 3D printing for rapid prototyping and production in as fast as 1 day. Just upload a 3D CAD file to get an instant quote on your 3D printing design. In our quoting platform, you can see real-time cost implications based on your choice of 3D printing material and resolution level.

Click here > https://projet.my/instant-3d-printing-online/

Our achievements so far

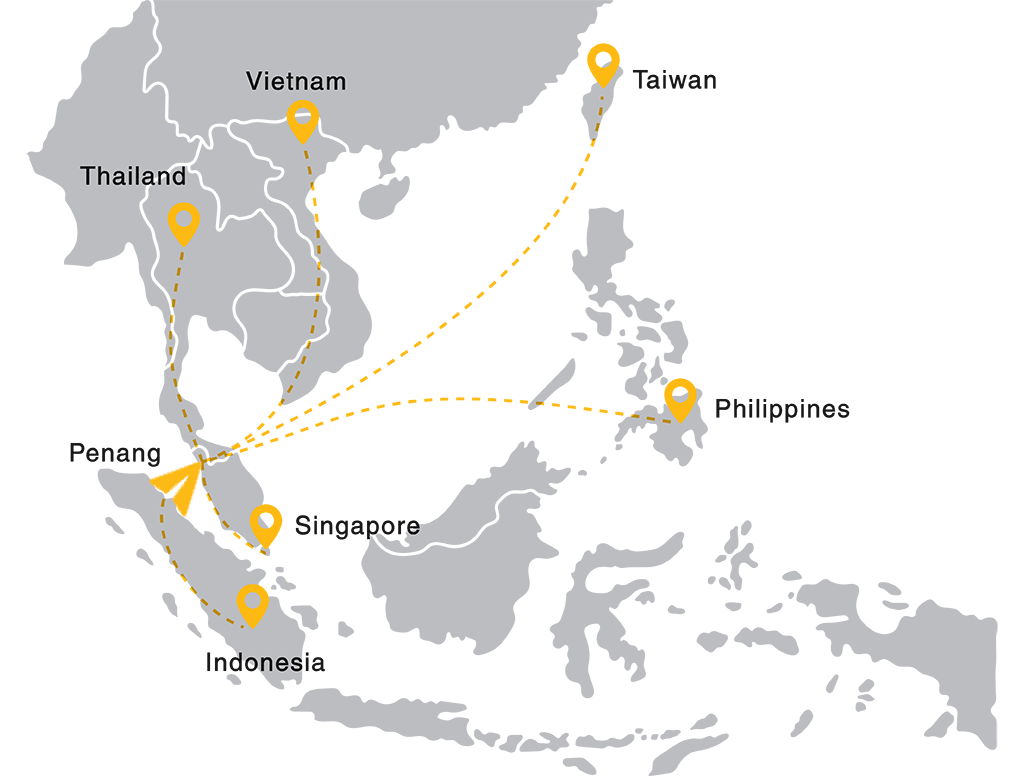

Clients from across the region

Communication and commuting are the keys to our business. Our technical team members speak multiple languages to effectively communicate with clients from different countries, diverse communities, and backgrounds.

We take pride in the convenient access to logistic channels at our location, allowing us to deliver the ‘masterpieces’ to our clients speedy and efficiently to countries like Singapore, Thailand, Indonesia, Taiwan, Philippines and Vietnam.

Our clients' testimonials

Our clients' testimonials

My experience with Projet has been nothing but exceptional. Over the last 2 years, we have undertaken numerous projects with them, from gauges, jigs, and fixtures to end-use products, and they consistently delivered an outstanding job with high-quality results.

Brandon

(E&E)

I highly appreciate working with the company. Their response time is quick, their prices and lead times are excellent, and the products I've received have been outstanding. I can't recommend them enough!

Ng K.

(Medical)

They offers "Additive Manufacturing" education sharing day session. The program not only increased students awareness of this fascinating technology but also provided a clear understanding of how it's shaping the future. The sessions were well-organized, with engaging presentations and valuable insights. Highly recommended for anyone curious about the future of manufacturing!

Dr.Zaini

(Education)

We experienced excellent service from technical team throughout the entire process – from sales and production to delivery and installation. We purchased machine service packages and utilized their 3D printing services. Alex consistently kept us informed about the progress, asked relevant questions, and ensured our satisfaction with the product we would be receiving.

TK Ong

(Automation)

Projet is all you need when designing custom mechanical parts. Their engineering teams helped me address design concerns and choose the correct printing process for my projects.

Prof. May

(Education)

The prototype parts were of great quality and printed at the highest standards. I'm especially impressed with the accuracy and surface finishing. Their 3D print service is consistently top-notch. I highly recommend the services of this company.

Dr. Adam L.

(Aerospace)

Projet has truly opened doors for me with their rapid prototyping, mechanical design, custom 3D printing, and laser services. Their skilful engineers worked closely with me on my project to ensure the parts were produced to our specifications. The customer service is always prompt, helpful, and willing to provide valuable advice.

James T

(Consumer Electronics)

We required low-volume production with a short lead time, and Projet was able to support us with quick turnaround times. Allen and the team consistently provided exceptional customer service, making the entire process seamless. Highly recommended! Thanks for having our back, guys!

CL

(Automotive)

We were initially hesitant to order from this company, but after 2 orders, we are very pleased that we gave it a try! Good service, deliveries faster than expected, and the quality is excellent! Nothing bad to say. Better than expected.

Hilmi

(Agriculture)

They gave made the process of building custom parts easier than I ever imagined. The parts turned out exactly as designed, and the timing was as expected. It was an overall positive experience, and I'm particularly satisfied with the results, especially the surface finishing and high-quality painting jobs.

Jennifer

(Architecture)

We engaged Projet for reverse engineering for my machine components, the experience was outstanding. The customer service, particularly from Jin was top-notch, ensuring a smooth and satisfactory process throughout.

Dr. Yang

(Medical)

We received excellent results with the complex CNC parts from Projet. Their work aligned perfectly with the schedule and budget of our project. The precision and quality of the CNC machining from Projet were excellent, exceeding our expectations.

Judy

(Semiconductor)

I approached Projet for cosmetic prototyping as part of our soft launch for new products in the market. They guided me through the entire project, from mechanical design and custom 3D printing to the painting process. Their service was excellent, with quick responses to our requests. The shipment arrived earlier than expected and the quality exceeded our expectations.

Zulkifli

(FMCG)

I needed a project for my final year, and I had a rough idea of what I wanted. Their engineering team helped refine my design and addressed all my concerns. The 3D prototype they provided was detailed and well-crafted. I highly recommend their 3D printing services!

Danish

(USM Student)

We experienced excellent service from Projet. Their engineering team provided invaluable advice on selecting the best materials and print options for our model. The quality of small, detailed parts was excellent. Projet is highly recommended for their helpfulness and efficiency, from design discussions through to delivery, and their keen interest in meeting our needs.

Sophia

(E&E)

I needed a prototype to present to my funder, and they delivered it quickly within my timeline, adapting perfectly to my requirements. If you need a product or project 3D printed, I highly recommend Projet. Their 3D printing technology promises to turn any idea into reality.

Azim

(Inventor)

They provided a fair quote and successfully manufactured a scale model of our factory. While the lead time was not the shortest, it was acceptable given the high quality. The parts have consistently met our standards, with excellent quality nearly every time.

Amanda

(Medical)

I was really impressed with the 3D printing instant quote system! It was super easy to use, incredibly fast, and I got my quote in no time. The whole process was smooth and hassle-free from start to finish. Plus, the quick delivery exceeded my expectations. Highly recommend for anyone looking for a seamless 3D printing experience!

Cheng

(E&E)

Start your next project with us today

Manufacturing limitless possibilities with industrial fabrication solutions.

Your one-stop destination for rapid prototypes and custom parts

We guarantee consistent quality for complex prototypes and end-use parts.

- From rapid prototyping to on-demand production.

- Lead times from 3 business days

- All uploads are secure and confidential

Successfully assisted

Our Manufacturing Capabilities

We are a highly dependable mechanical powerhouse with an extensive array of manufacturing capabilities. Catering to both one-off prototyping and low-volume production, we offer solutions that span from basic to industrial, including advanced cosmetic finishing manufacturing.

3D Printing

FDM, SLA, SLS

- Tolerances down to ± 0.2 mm

- Class 1 visual finishing

- Basic to engineering grade material

Laser Cutting

CO2 Laser Cutting

- Tolerances down to ± 0.3 mm

- Metal, plastic, foam, wood

Vacuum Casting

Vacuum Casting

- Tolerances down to ± 0.3 mm

- High transparency

- High performace production-like parts

CNC Machining

Milling, Turning

- Tolerances down to ± 0.03 mm

- Up to 5 axis

Rapid prototyping to volume production

Projet actively revolutionizing with technology – propelling entire industries forward by showcasing its impact in every stage, from rapid prototypes to crafting end-use parts that redefine efficiency.

This isn't just a vision – it's the reality we're shaping. We've pioneered a groundbreaking solution that revolutionizes how parts are designed and prototyped. By leveraging the unique abilities, we're able to speed up product development, offer cost-effective low-volume manufacturing with no minimum order quantity, and shore up manufacturing workflows.

Rapid Prototyping

Prototype like a PRO! With Projet, you can transform your ideas into masterpieces in days, not weeks.

- May not be as refined, focus on functionality

- Prototypes material specifications

- Limited / One-offs or small batches

- Concept models / Functional prototypes

Volume Production

Time is money, and we're saving you both. Think of us as your production time machine. We'll warp your volume orders from months to weeks, leaving you with more time to focus on what matters most.

- High-quality finish, meets market standards

- Durable and long-lasting materials specifications

- Low mix high volume / High mix low volume

- Custom end-use parts / Mass customization