Additive manufacturing (AM), also known as 3D printing, is a digital technology that’s revolutionizing the medical industry.

Additive manufacturing (AM) is revolutionizing the production of medical devices and other specialized products. This technology is used to create custom, intricate designs for items like dental implants, heart valves, joint replacements, orthoses, prostheses, medical models, and inert implants.

One of AM’s biggest advantages is its ability to improve patient outcomes while minimizing the need for additional surgeries. By reducing downtime for critical medical equipment, AM helps ensure better reliability in healthcare settings.

With the rising demand for medical tools and prosthetics, companies are constantly seeking efficient and cost-effective ways to produce lightweight, complex medical components. Additive manufacturing, often called the “next industrial revolution in manufacturing,” offers a game-changing solution. It enables the creation of detailed, patient-specific parts on demand, making it a key focus in the medical industry today.

Benefits of Additive Manufacturing in the Medical Industry

Personalized Medical Devices and Implants

Additive manufacturing is revolutionizing the healthcare industry by enabling the creation of highly personalized medical devices and implants. This advanced technology uses detailed 3D scans of a patient’s anatomy to design solutions tailored to their unique needs. As a result, devices and implants fit perfectly, offering superior functionality and comfort.

Custom-fit implants and prosthetics not only enhance the recovery process but also boost overall patient satisfaction. By ensuring an optimal fit, these personalized solutions make recovery faster and more comfortable, improving both the experience and outcomes for patients.

Lower Product Development Costs

Additive manufacturing significantly reduces the expenses associated with product development. By streamlining processes and minimizing material waste, manufacturers can create innovative medical devices and tools more cost-effectively.

Faster Prototyping and On-Demand Manufacturing

Additive Manufacturing Technology (3D Printing) enables rapid prototyping, allowing designers to quickly create and test new medical products. Additionally, on-demand manufacturing eliminates the need for large inventories, as parts can be produced when and where they are needed.

Unmatched Customization

A standout advantage of 3D printing is its ability to deliver highly personalized solutions. From patient-specific implants to custom surgical tools, additive manufacturing caters to individual needs with precision.

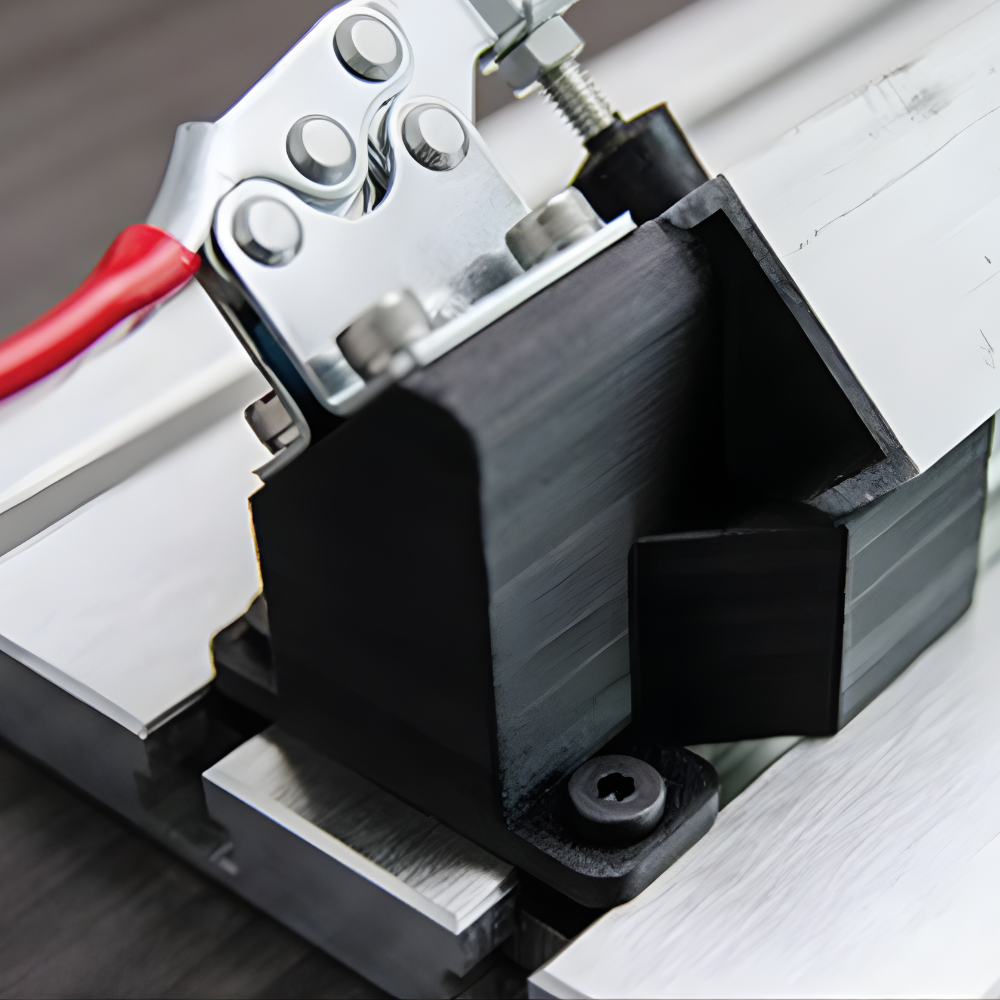

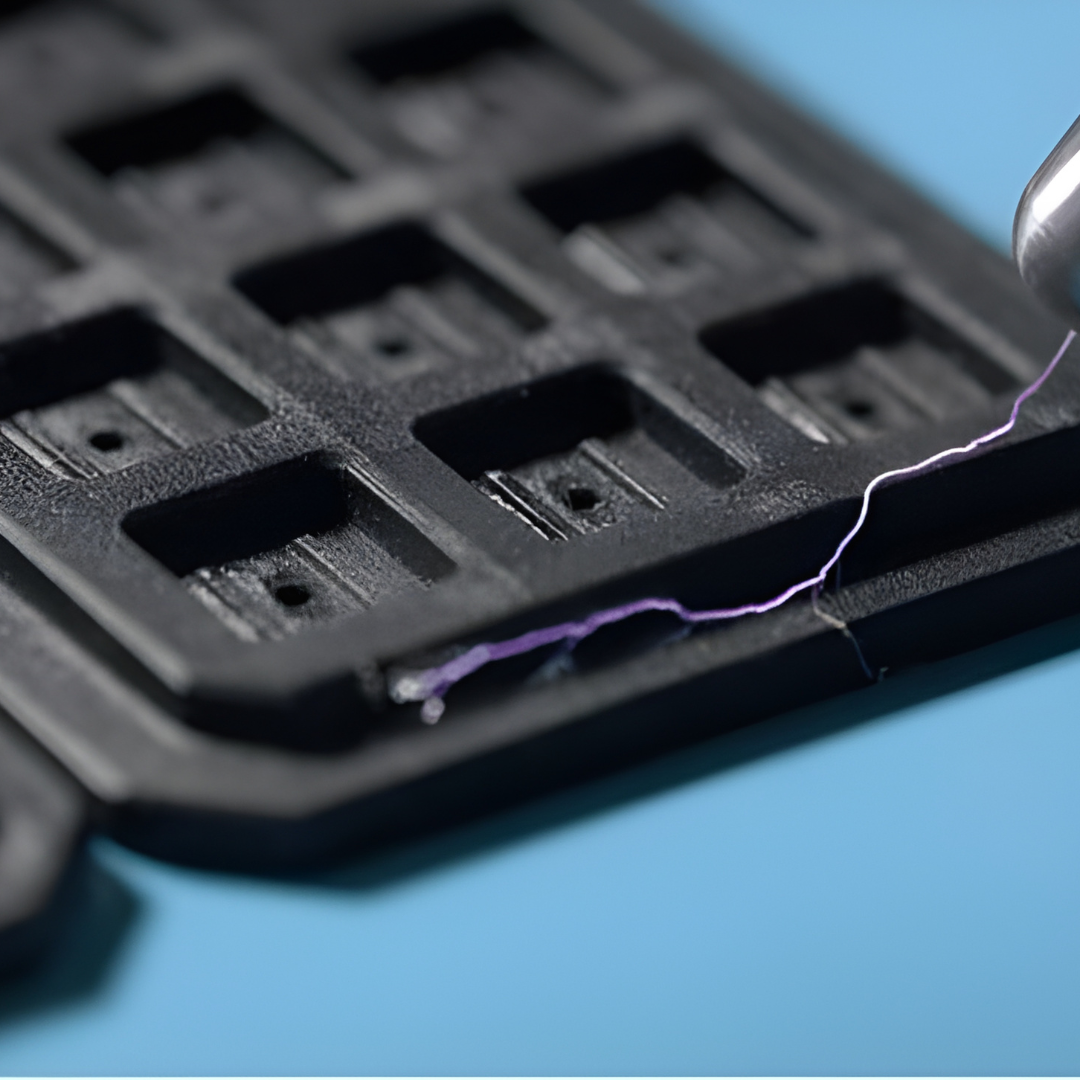

Simplified Production of Complex Parts

With additive manufacturing, complex designs and intricate structures can be created in a single step. This reduces the need for assembling multiple components, saving both time and resources.

3D Printing Service Malaysia , 3D Printing service Singapore , 3D Printing service KL , 3D Scanning Malaysia

Collaborate with 3D printing bureau to choose the best material and optimize build orientation for your project’s needs. Explore our 3D Printing Materials Guide to learn about various plastic and metal materials across technologies.

Discover more about additive manufacturing at projet.my. For assistance, reach out to our applications engineer at enquiry@projettech.com or +604-2858 335.