HP’s Multi Jet Fusion (MJF) technology leads the 3D printing industry by delivering a powerful mix of speed, high-quality results, and cost-efficiency.

This innovation has revolutionized prototyping and production, helping businesses launch new products faster and more efficiently.

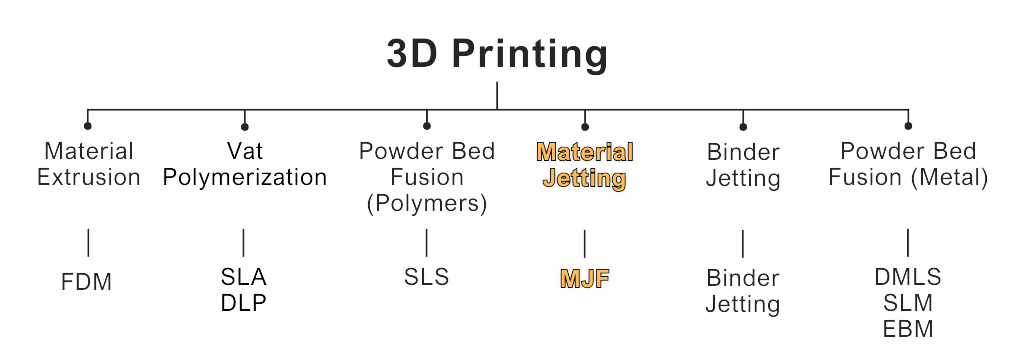

What is Multi Jet Fusion (MJF) 3D printing?

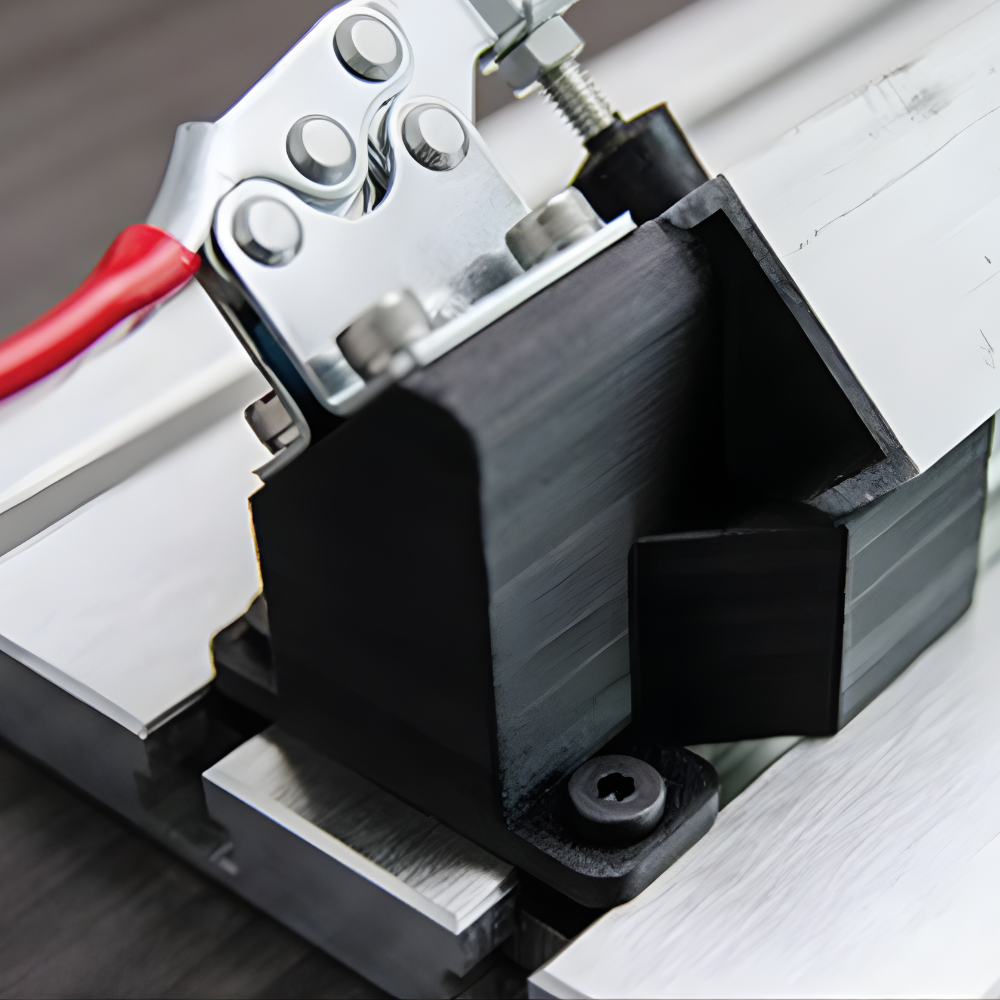

Multi Jet Fusion (MJF) is a fast, industrial 3D printing process that creates high-quality nylon prototypes and production parts, often in just one day. Multi Jet Fusion (MJF) delivers smoother surfaces, finer details, and more uniform mechanical properties compared to techniques like selective laser sintering (SLS). This advanced technology provides high-quality finishes and reliable strength, making it ideal for precision 3D printing. This makes MJF an ideal choice for high-quality, durable parts with a refined finish.

Common uses for Multi Jet Fusion include:

- Parts needing uniform, strong mechanical properties

- Functional prototypes and finished production parts

- Complex shapes and intricate designs

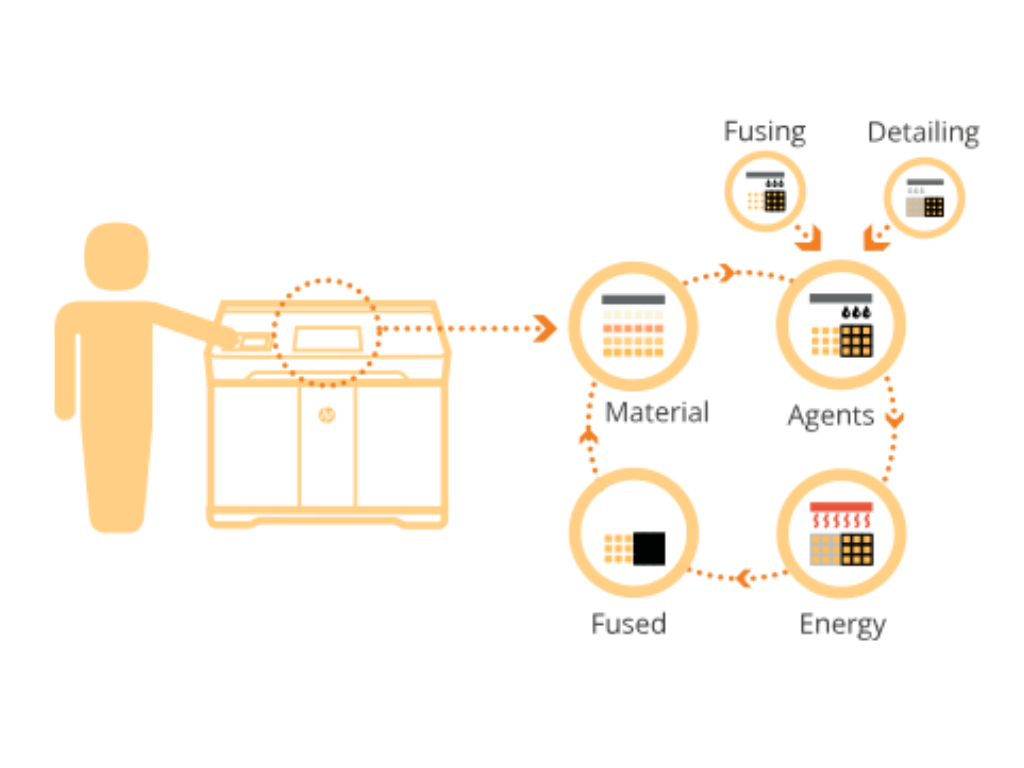

How Does an MJF 3D Printer Work?

MJF (Multi Jet Fusion) uses an inkjet array to precisely apply fusing and detailing agents onto a powder bed, layer by layer, to build parts. Here’s how it works:

- The printer’s build unit is positioned inside the machine.

- The recoater evenly spreads a fine layer of powder over the build area.

- The printing carriage heats the powder to maintain material consistency.

- Inkjet nozzles apply fusing agents in the specific areas to define part shape and properties.

- After each layer, the build unit lowers to make space for the next layer of powder.

This cycle repeats until the part is fully formed. Once printing is done, the part cools in a processing station that also recycles unused powder. Bead blasting then removes remaining powder, preparing the part for final finishing.

3D Printing FDM , 3D Printing service Singapore , 3D Printing service KL, 3D Printing SLA, 3D Scanning Malaysia

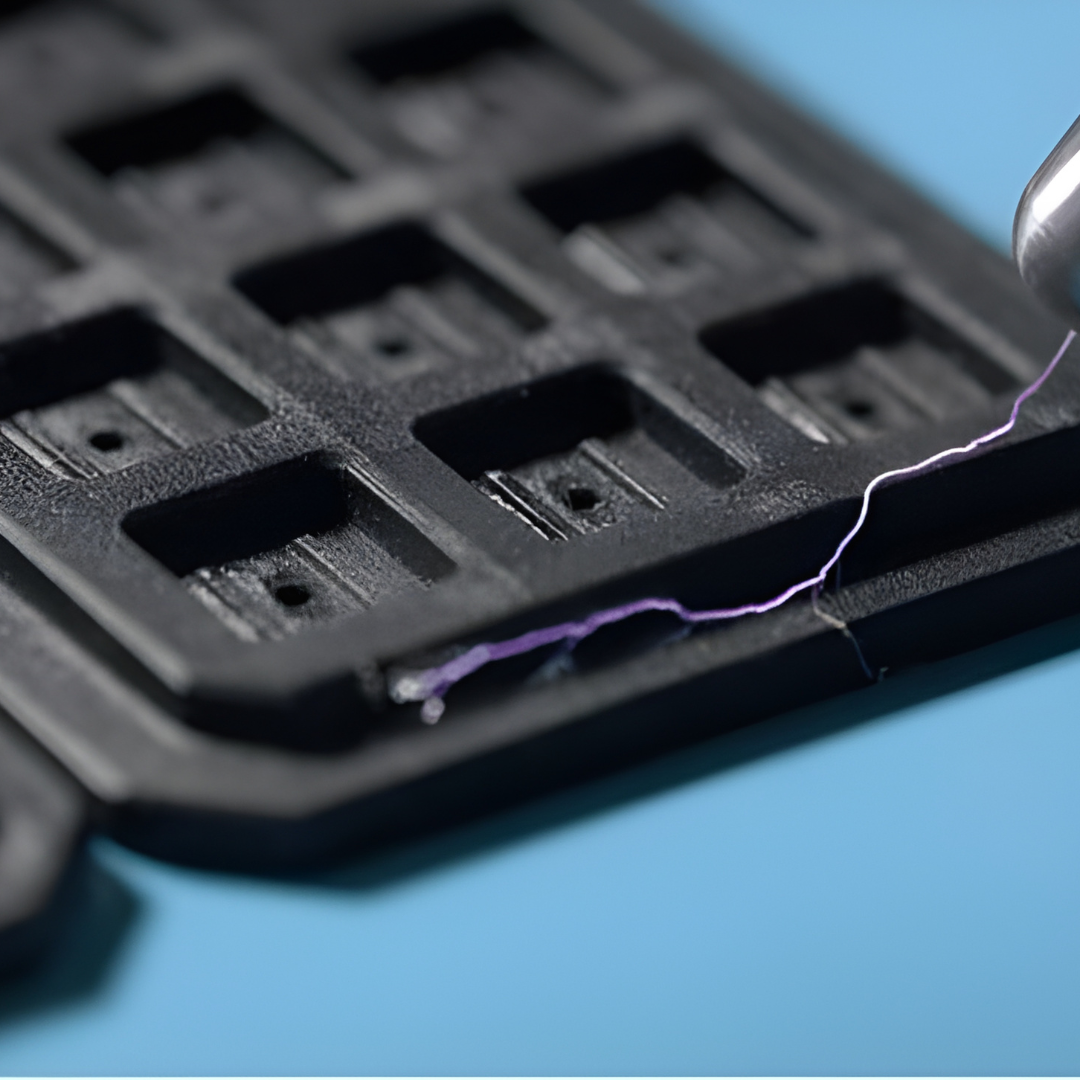

No Need for Support Structures in MJF 3D Printing

Multi Jet Fusion (MJF) technology eliminates the need for traditional support structures, which are usually required in 3D printing to hold complex designs in place during production. With MJF, parts can be printed directly without supports, making the process faster, more efficient, and less wasteful. This means reduced costs and shorter production times, making it ideal for both prototypes and end-use parts.

Brief History and Evolution of MJF Technology

HP introduced Multi Jet Fusion (MJF) technology in 2016, leveraging its decades-long expertise in inkjet printing and precision mechanics. While MJF launched in 2016, its development roots trace back many years prior within HP’s innovation journey.

3D Printing service malaysia

3D Printing service malaysia

What are the advantages of MJF 3D printing?

If you need to create durable prototypes or small production runs of functional end-use parts, Multi Jet Fusion (MJF) is an ideal solution. MJF technology excels at producing stronger parts than those made with Selective Laser Sintering (SLS).

One of MJF’s biggest advantages is that it can produce ready-to-use parts with minimal post-processing, making it highly efficient. Compared to other additive manufacturing (AM) methods, MJF offers faster production speeds and more advanced automation. This leads to shorter lead times and high-quality surface finishes, all with minimal human involvement.

What Materials are Available for MJF 3D Printing?

Materials used for MJF 3D printing can be divided into two categories:

Rigid plastics: Nylon PA11, Nylon PA12, PP, Nylon PA12 Glass Beads

Flexible plastics: TPU M95A , TPA

Collaborate with 3D printing bureau to choose the best material and optimize build orientation for your project’s needs.Explore our 3D Printing Materials Guide to learn about various plastic and metal materials across technologies.

Discover more about multi jet fusion at projet.my. For assistance, reach out to our applications engineer at enquiry@projettech.com or +604-2858 335.