Over the past decade, technological advancements have positioned resin 3D printing, or vat photopolymerization, as a leading method for creating highly detailed 3D-printed parts. This technique is widely used for rapid prototyping, rapid tooling, manufacturing aids, and even end-use components.

Its popularity is driven by its high accuracy, fast printing speeds, a broad selection of materials, and isotropic mechanical properties, making it a versatile choice for various applications in the industry.

This comprehensive guide compares SLA, DLP, and MSLA/LCD 3D printers, focusing on critical factors such as print resolution, accuracy, precision, and surface finish. By understanding the strengths and limitations of each, you’ll be able to choose the 3D printing technology that aligns with your project needs and production goals.

What is SLA 3D Printing?

Stereolithography (SLA)

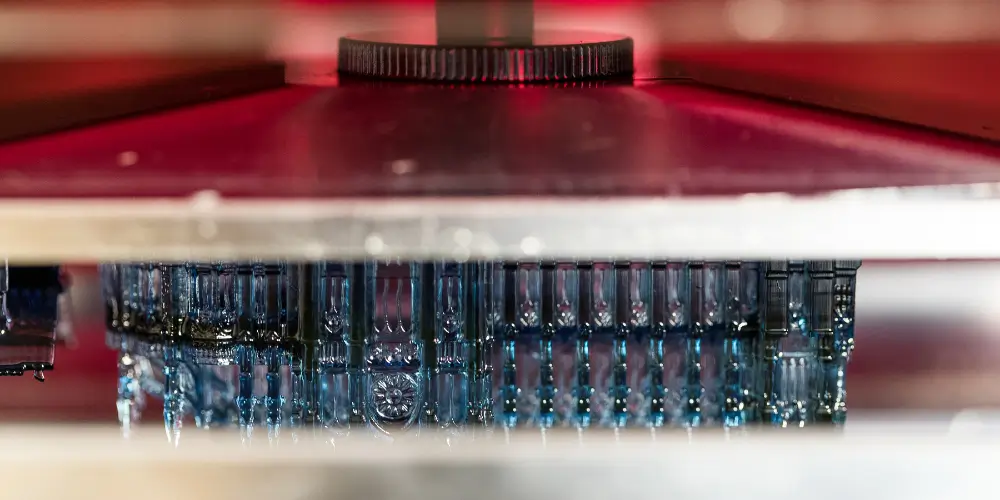

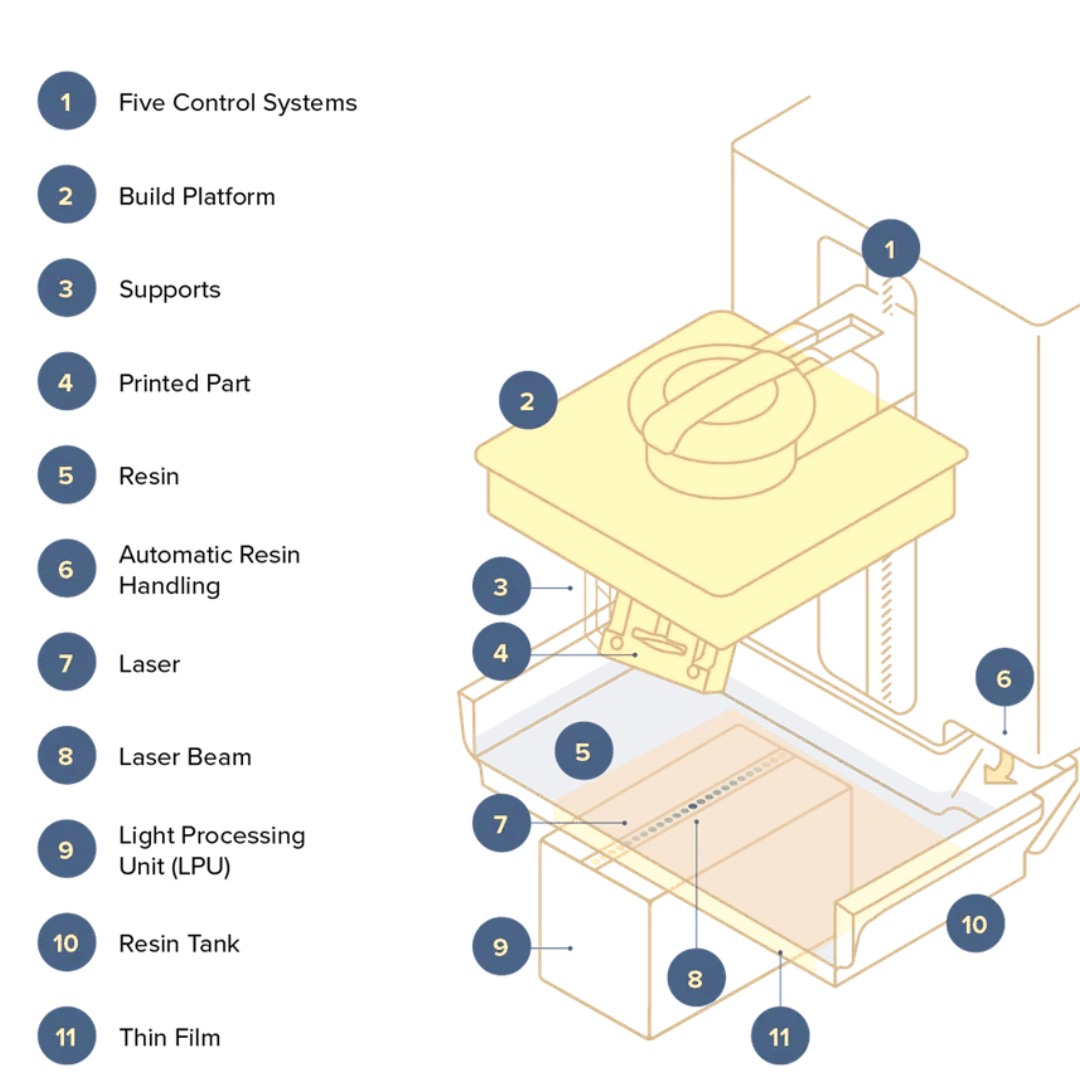

Stereolithography (SLA) is a popular additive manufacturing technique under vat photopolymerization. It uses UV laser beams to cure liquid polymer resin layer by layer, creating 3D objects. This process involves photosensitive thermoset polymers that solidify when exposed to UV light, making SLA a widely-used 3D printing technology.

What is DLP 3D Printing?

Digital light processing (DLP)

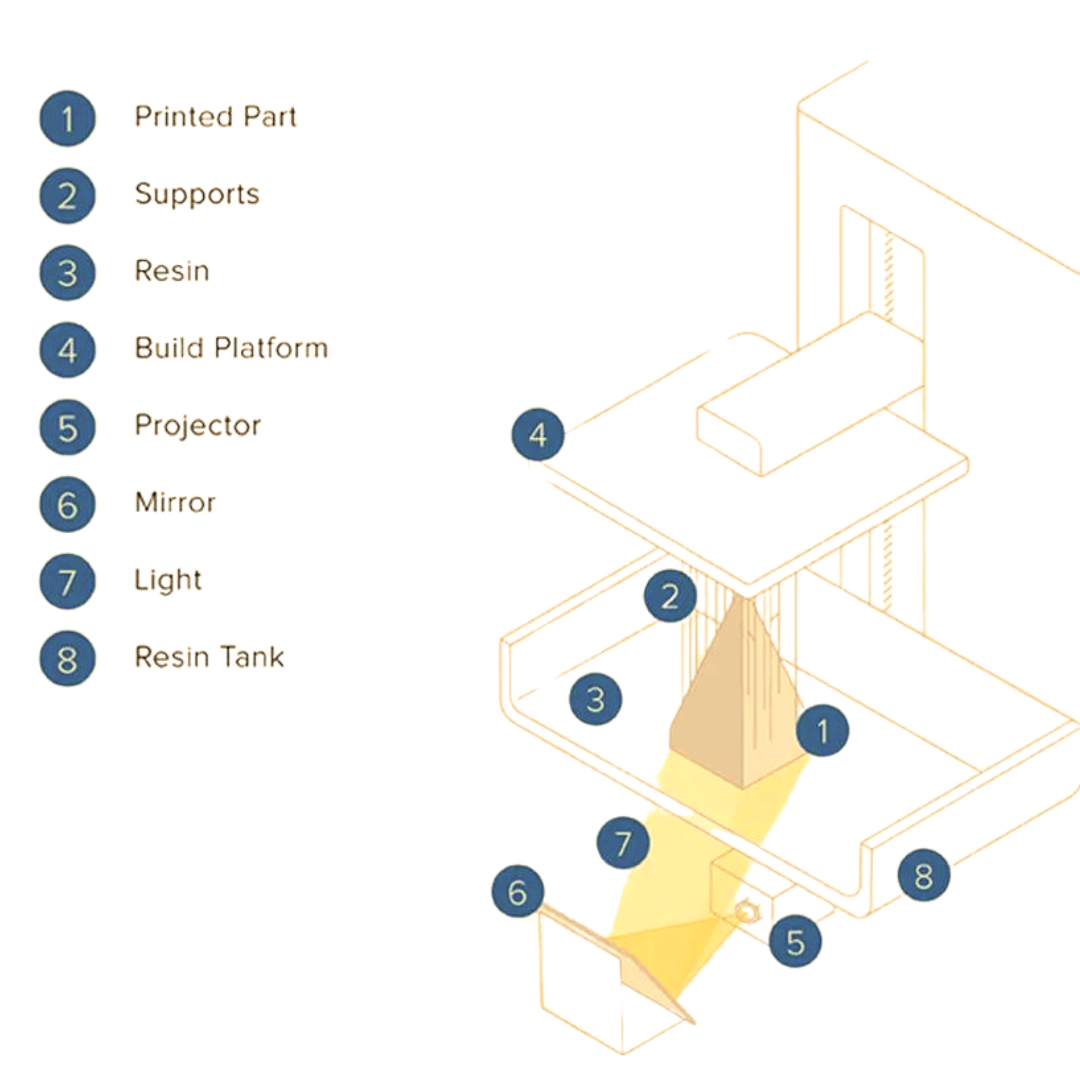

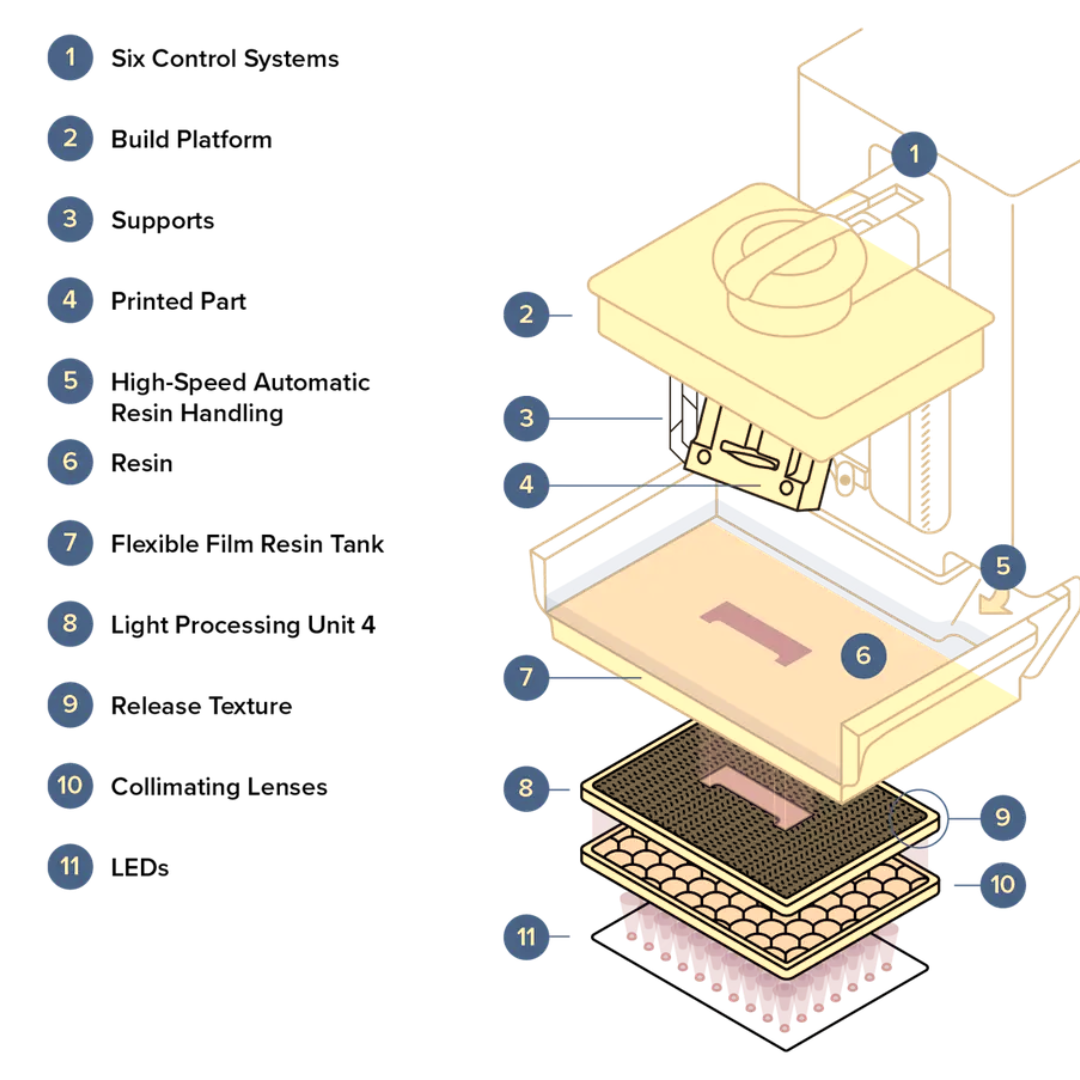

Digital Light Processing (DLP) technology utilizes a digital light projector to cure resin by projecting full-layer images onto the bottom of the vat. This method precisely directs light through a digital micromirror device (DMD), consisting of hundreds of thousands of tiny mirrors.

What is MSLA 3D Printing (or LCD 3D Printing)?

Masked stereolithography (MSLA)

Masked Stereolithography (MSLA) 3D printing is an advanced photopolymerization technique that selectively cures liquid resin using a masked light source. Though commonly associated with LCD 3D printing, MSLA applies to any masked resin 3D printing method. Its versatility allows for different light sources and masking techniques, offering exceptional adaptability in 3D printing.

Comparing SLA, DLP, MSLA/LCD 3D Printing Processes

Laser-powered SLA, DLP, and MSLA/LCD 3D printers are all variations of stereolithography that use light to cure liquid resin. The key distinctions between these resin 3D printing technologies lie in factors such as surface finish, resolution, accuracy, and precision. These differences are primarily influenced by the specific light source and processing methods unique to each technique.

Surface Finish

In SLA 3D printing (left), layer lines are almost imperceptible, which significantly reduces surface roughness. This results in smoother finishes and, for clear materials, more translucent parts. On the other hand, DLP and MSLA/LCD 3D printing rely on rectangular voxels to form images, often leading to visible vertical voxel lines (right).

Resolution

For SLA (Stereolithography) printers, several key factors impact performance. These include the laser spot size, laser power distribution, the precision of the galvanometer in the XY plane, and the minimum layer height along the Z-axis.

On the other hand, DLP (Digital Light Processing) printers rely on factors like pixel size, light power and uniformity, anti-aliasing techniques, and the layer height on the Z-axis.

Similarly, MSLA (Masked Stereolithography) printers are affected by the LCD pixel size, the collimation and uniformity of the light source, anti-aliasing methods, and the minimum Z-axis layer height.

Accuracy & Precision

The accuracy of LCD and MSLA 3D printers depends on factors like light source uniformity, collimation, pixel size, and LCD quality. Conversely, DLP printers struggle with pixel distortion at build area edges, as their micromirror devices project light over longer distances, leading to reduced precision in those areas.

Connect with Projet:

If you’ve had a positive experience with Projet that you’d like to share, please reach out to us at enquiry@projettech.com. We eagerly anticipate hearing from you.

For additional information, visit our website for comprehensive details about our services and contact information. Our friendly team is ready to assist you at any time.