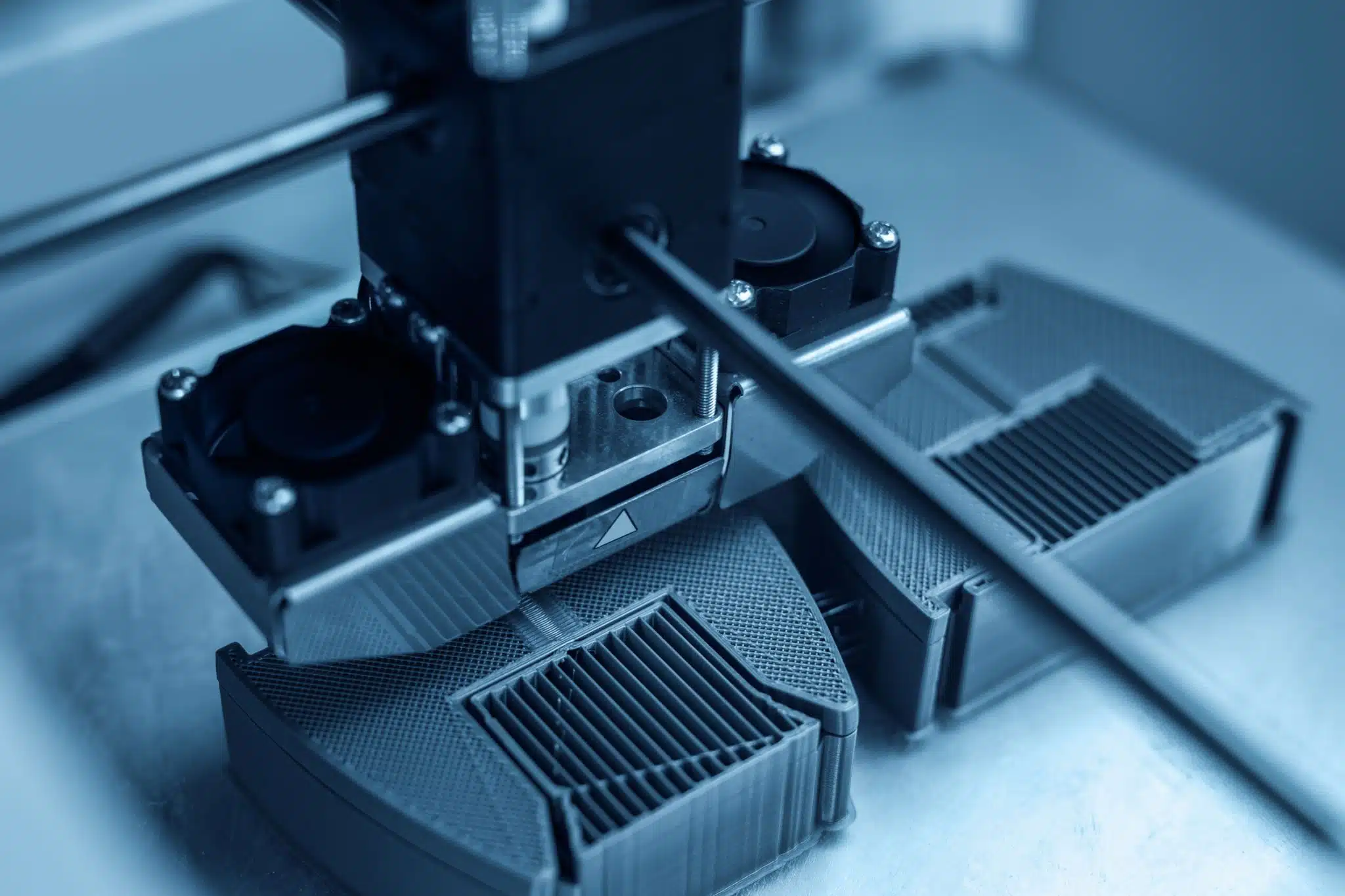

What Is Additive Manufacturing?

In general, the most commonly used term is “3D printing”. But the industrial world chooses to use the term “additive manufacturing”, from the English “direct manufacturing”.

Additive manufacturing can cover all the various techniques that can be applied to various materials. The manufacturing is done by adding, layer by layer, of material, thus allowing it to pass from the virtual part to the manufactured part.

Advantages of additive manufacturing in research and development phase

• Rapid Prototyping:

Additive Manufacturing (AM) significantly enhances the prototyping process by enabling rapid and cost-effective production of prototypes. This technology allows for faster iterations during the design phase, enabling quick testing of various projects and concepts. As a result, improvements can be promptly implemented, significantly reducing the time required to develop the final product.

– Accelerates prototype production

– Enables quick design iterations

– Reduces development time

• Design Flexibility:

Unlike traditional manufacturing, Additive Manufacturing (AM) offers greater design freedom. Complex geometries and customized components can be easily produced, leading to innovative designs and improved product performance.

– Allows for complex geometries

– Facilitates innovative designs

– Enhances product performance

• Cost Efficiency:

Additive Manufacturing (AM) significantly lowers production costs by eliminating the need for complex tooling and minimizing material waste. Unlike traditional prototyping methods, which can be expensive due to the requirement for tools or molds, AM provides a more cost-effective alternative.

– Eliminates need for complex tooling

– Minimizes material waste

– Reduces production costs

• Shortened Lead Times:

Additive Manufacturing (AM) drastically reduces lead times by enabling the rapid creation of prototypes and functional parts. What once took an 9 week production process can now be accomplished in just a few days, showcasing AM’s transformative impact on production efficiency.

– Speeds up prototype and part creation

– Cuts production process from weeks to days

– Increases production efficiency

• Customization:

Researchers can tailor components to meet specific requirements, resulting in better-fit solutions for a wide range of applications. This customization capability ensures that the final products are more precisely aligned with their intended functions and performance criteria.

– Tailor’s components to specific needs

– Ensures better fit solutions

– Aligns products with performance criteria

Connect with Projet:

If you’ve had a positive experience with Projet that you’d like to share, please reach out to us at enquiry@projettech.com. We eagerly anticipate hearing from you.

For additional information, visit our website for comprehensive details about our services and contact information. Our friendly team is ready to assist you at any time.

<meta name=”google-site-verification” content=”MnSJHRG6ALZ5y1rwnqI-Kj-9-pQPUfD6Tpgu1qg1MOA” />