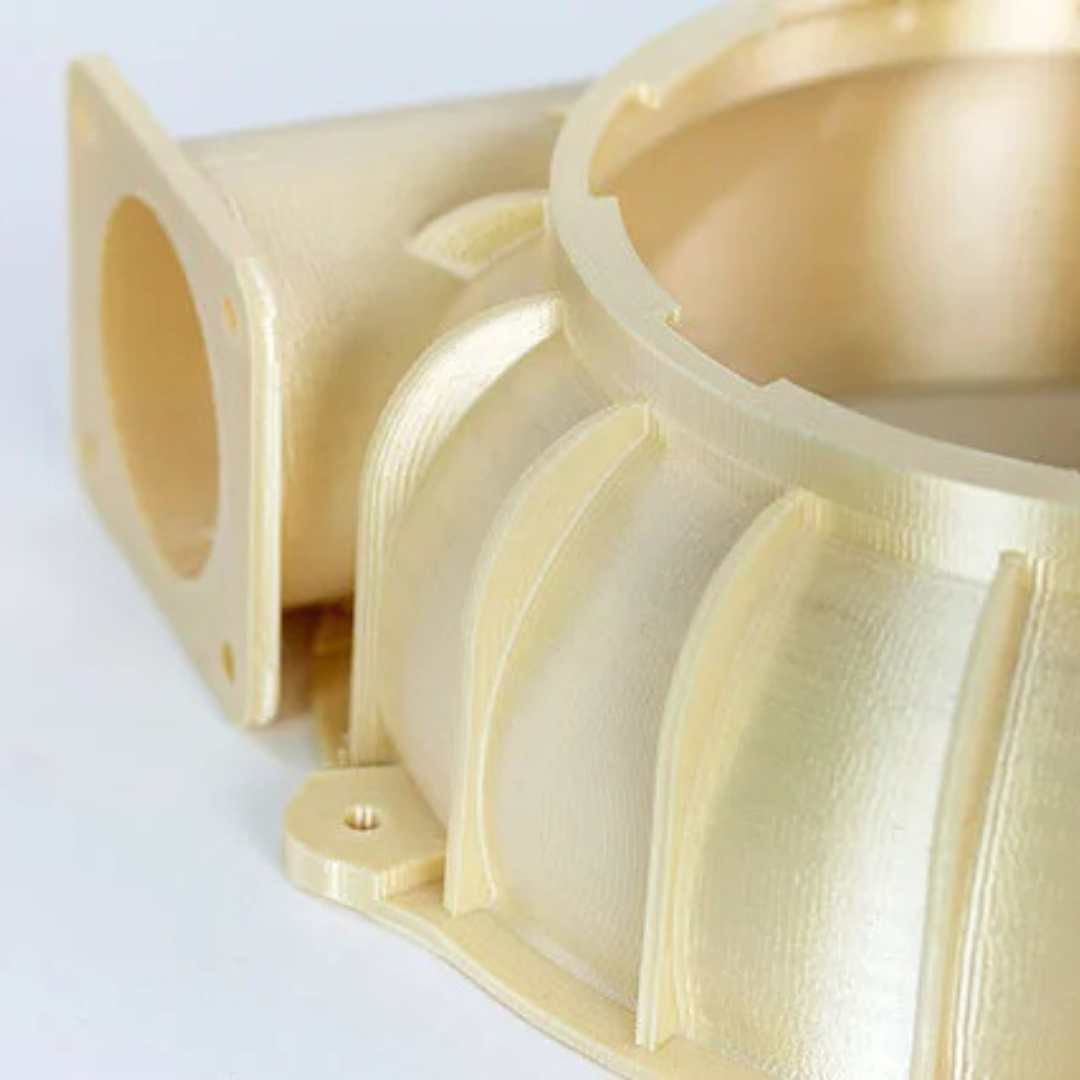

Among the many 3D printing materials available, ULTEM, also known as PEI (Polyetherimide), is a standout high-performance thermoplastic. It offers exceptional strength, heat resistance up to 180ºC, and impressive chemical resistance to both natural and synthetic solvents.

Additionally, ULTEM boasts high dielectric strength and good thermal conductivity. Although it has slightly lower strength, stability, and creep resistance compared to PEEK and PEKK, ULTEM remains a popular choice for metal part replacements.

Its versatility makes it especially valuable in industries like aerospace, automotive, and railroads, where performance and reliability are critical.

Why is it unique?

ULTEM is part of the family of amorphous thermoplastics, which means it lacks a crystalline structure, resulting in unique mechanical and thermal properties. ULTEM is known for its exceptional strength, heat resistance, chemical resistance, and flame retardancy. It was developed by SABIC Innovative Plastics (formerly General Electric Plastics) and is widely used in various industries for applications that require robust, high-performance materials.

Different grades and their specific applications of ULTEM

ULTEM 1000 is the standard grade of ULTEM, offering a well-rounded combination of mechanical, thermal, and electrical properties. Known for its high strength, rigidity, and excellent chemical resistance, it is a versatile material suitable for a wide range of applications.

ULTEM 1010 is a high-performance grade designed for improved flow and ease of processing, which enhances moldability. Along with its strength and rigidity, it also boasts excellent chemical resistance and flame-retardant properties. Select grades meet the stringent UL94V-0 flammability standard, making it ideal for safety-critical applications.

ULTEM 9085 is distinguished by its high strength-to-weight ratio, exceptional heat and chemical resistance, and flame-retardant properties. These characteristics make it the go-to material for producing components used in aircraft interiors, piping systems, electrical enclosures, and other high-performance environments.

ULTEM 9085 vs ULTEM 1010

When it comes to ULTEM materials for 3D printing, there are two main variants to consider: ULTEM 9085 and ULTEM 1010. Both materials offer excellent heat and chemical resistance, along with a high strength-to-weight ratio. Additionally, they are certified with UL94 V0 and FST ratings, making them suitable for demanding applications.

For projects that prioritize high strength and flexibility, ULTEM 9085 is the ideal choice. On the other hand, if chemical resistance is a key requirement, ULTEM 1010 is the superior option.

Applications

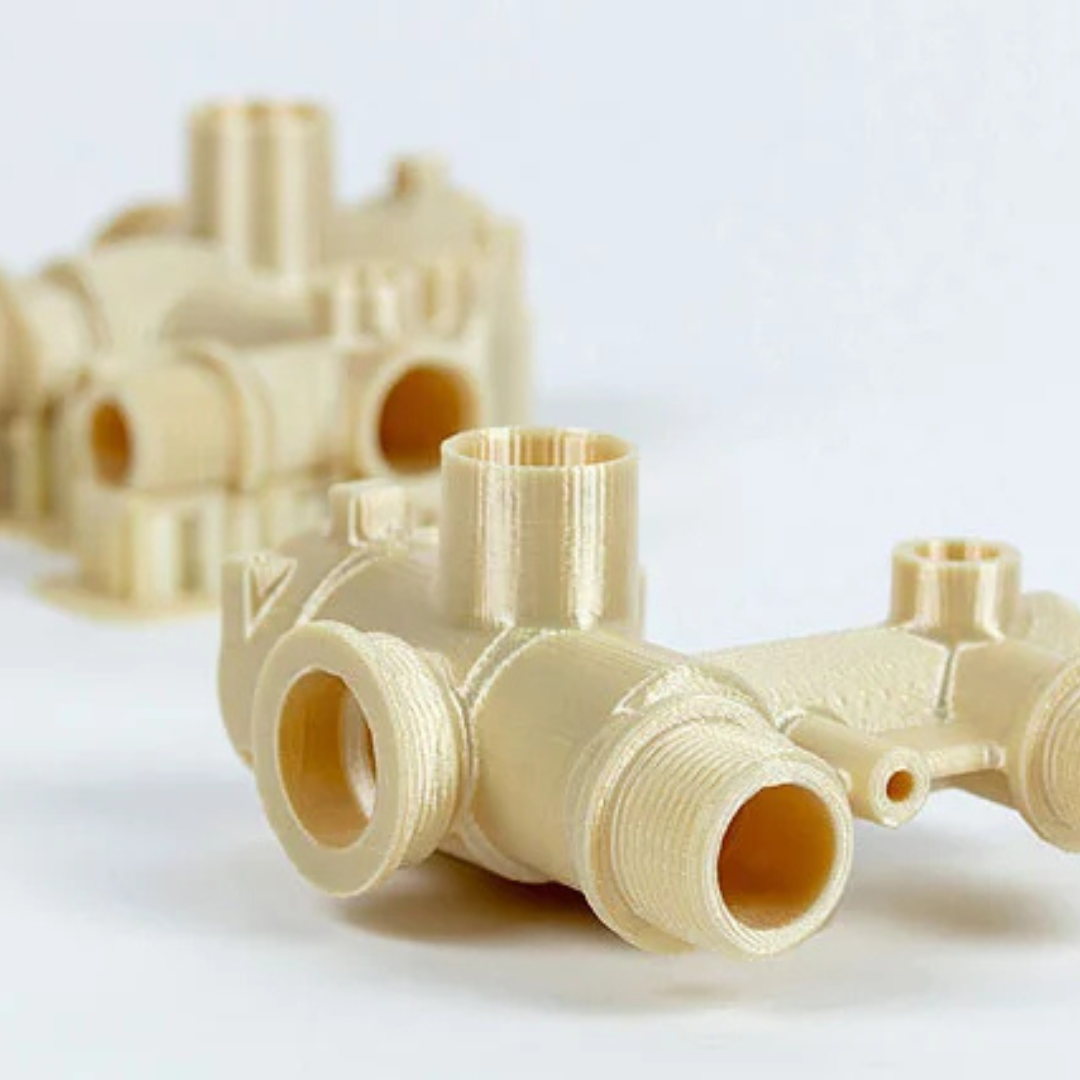

Aerospace: ULTEM is widely used in aerospace applications because of its exceptional strength, lightweight nature, and superior resistance to high temperatures and chemicals. Its application includes interior panels, brackets, electrical connectors, and ducting systems, where high performance is crucial.

Automotive: In the automotive industry, ULTEM is valued for its high mechanical strength, dimensional stability, and resistance to both chemicals and heat. It plays a critical role in components such as fuel systems, electrical connectors, sensor housings, and various under-the-hood parts.

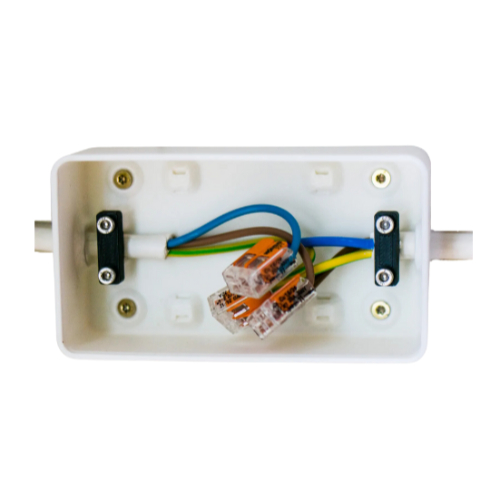

Electrical and Electronics: ULTEM’s excellent electrical insulation properties make it ideal for electrical and electronic applications. It is commonly used in connectors, sockets, insulators, coil bobbins, switches, and other components that require high-temperature resistance and superior electrical performance.

Medical and Healthcare: Due to its biocompatibility, sterilizability, and chemical resistance, ULTEM is an essential material in medical and healthcare applications. It is found in surgical instruments, medical device housings, orthopedic implants, dental tools, and equipment that requires high-temperature sterilization.

Consumer Products: ULTEM is also utilized in various consumer products where high performance and durability are paramount. It is found in sports equipment, mobile phone cases, laptop components, appliance parts, and other consumer goods that benefit from its strength, heat resistance, and chemical durability.

Industrial Equipment: In industrial applications, ULTEM serves as a reliable and robust material for demanding environments. It is frequently used in pump and valve components, fittings, gaskets, filtration systems, and other equipment exposed to harsh conditions or chemicals, ensuring long-lasting performance.

Connect with Projet:

If you’ve had a positive experience with Projet that you’d like to share, please reach out to us at enquiry@projettech.com. We eagerly anticipate hearing from you.

For additional information, visit our website for comprehensive details about our services and contact information. Our friendly team is ready to assist you at any time.