What is obsolete components EOL part?

An obsolete component, or “EOL part” (End-of-Life), is a part that is no longer manufactured or supported by its original manufacturer, potentially leading to challenges in maintaining or repairing products that rely on it.

Additive Manufacturing & 3D Printing: A Solution to End-of-Life Obsolete Components

In today’s fast-paced industrial landscape, innovation is the driving force behind progress. However, with rapid technological advancements comes a significant challenge: the obsolescence of components. As machinery, equipment, and systems evolve, older parts often become discontinued, leaving businesses scrambling to find replacements. This is where additive manufacturing, commonly known as 3D printing, emerges as a game-changing solution. By leveraging this cutting-edge technology, companies can breathe new life into obsolete components, ensuring operational continuity and cost efficiency.

The Problem of Obsolete Components

Obsolete components are a major challenge for industries like aerospace, automotive, healthcare, and manufacturing. When a part is discontinued, businesses are left with tough choices: spend heavily on custom replacements, redesign entire systems, or risk costly downtime. For industries using older, legacy equipment, the problem is even worse.

Traditional manufacturing methods often fail to solve these issues. Why? Because they rely on expensive tooling, take too long to produce parts, and require large production runs. This makes them inefficient and costly for addressing obsolete components.

In short, obsolete parts create unnecessary expenses, delays, and headaches—but there’s a better solution.

Enter Additive Manufacturing

Additive manufacturing, or 3D printing, is transforming industries by offering a revolutionary alternative to traditional methods. Unlike subtractive manufacturing, which cuts away material to create parts, 3D printing builds components layer by layer using digital 3D models. This eliminates the need for expensive molds or tooling, making it ideal for small-batch or custom production.

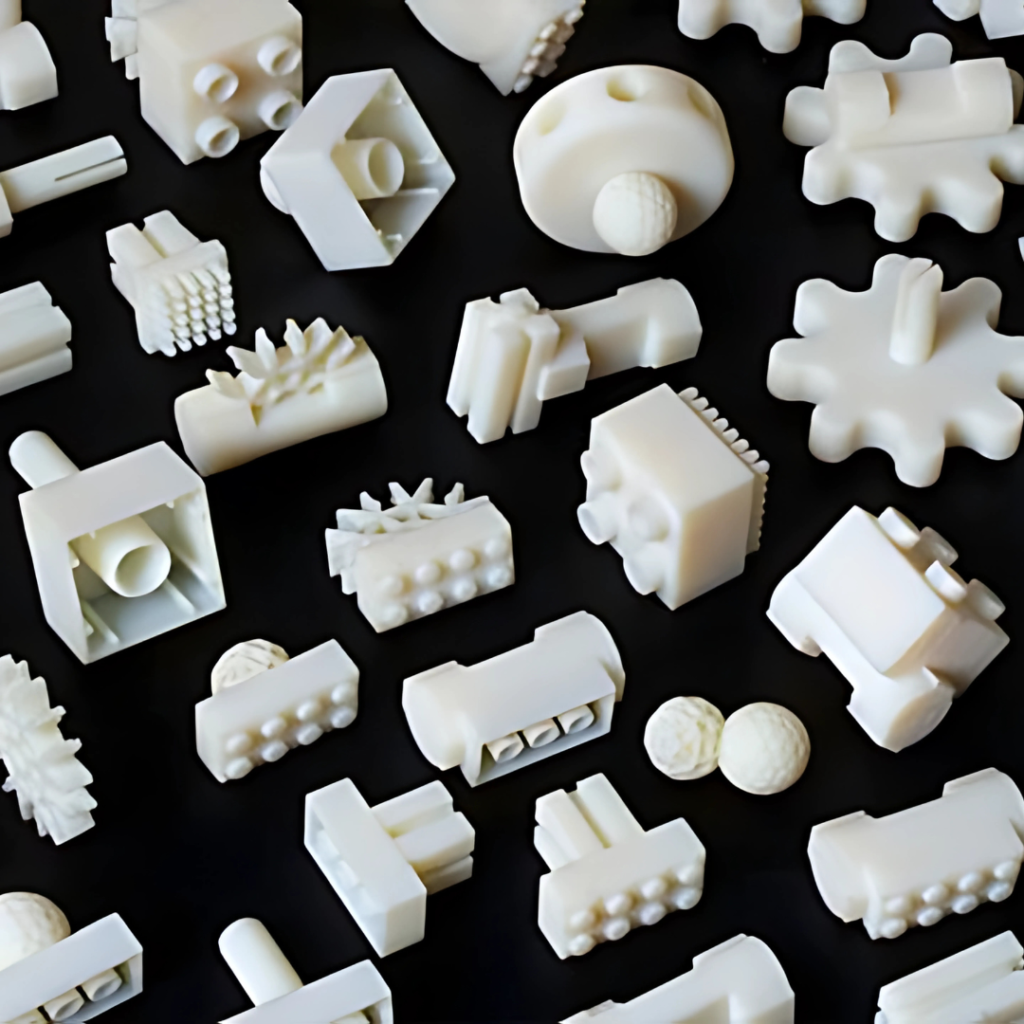

For obsolete components, 3D printing is a game-changer. By reverse-engineering original parts or using existing CAD files, manufacturers can recreate components with precision. Whether it’s a discontinued gear, a rare valve, or a custom bracket, additive manufacturing delivers these parts faster and at a lower cost than traditional methods.

In summary, 3D printing is the ultimate solution for tackling obsolete parts—saving time, reducing costs, and ensuring precision.

Benefits of 3D Printing for Obsolete Components

- Cost Efficiency: Traditional manufacturing methods often require significant upfront investment in tooling and setup. With 3D printing, these costs are drastically reduced, making it an economical solution for low-volume or one-off production.

- Speed: Additive manufacturing significantly shortens lead times. Once the digital design is ready, the part can be printed in hours or days, compared to weeks or months with conventional methods.

- Customization: 3D printing allows for easy modifications to the original design. If a component needs to be updated or improved, changes can be made to the digital model without additional tooling costs.

- Material Versatility: Modern 3D printers can work with a wide range of materials, including plastics, metals, and composites. This versatility ensures that the replicated part meets the required performance standards.

- Sustainability: By producing parts on demand, additive manufacturing reduces waste and minimizes the need for inventory storage. This aligns with the growing emphasis on sustainable practices in manufacturing.

Real-World Applications

The potential of additive manufacturing to address obsolete components is already being realized across industries. For example:

Aerospace: Airlines and manufacturers are using 3D printing to recreate discontinued parts for older aircraft, ensuring safety and compliance without grounding planes.

Healthcare: Hospitals are leveraging 3D printing to produce custom surgical tools and replacement parts for medical devices that are no longer in production.

Automotive: Classic car enthusiasts and repair shops are using 3D printing to restore vintage vehicles by recreating hard-to-find parts.